Synchronous machines operate at a constant speed synchronized with the supply frequency, offering precise control ideal for power generation and industrial applications, while asynchronous machines, also known as induction machines, run at speeds slightly less than the supply frequency and are valued for their ruggedness and simplicity in variable-speed applications. Explore the rest of the article to understand which machine aligns best with your specific needs and operational goals.

Table of Comparison

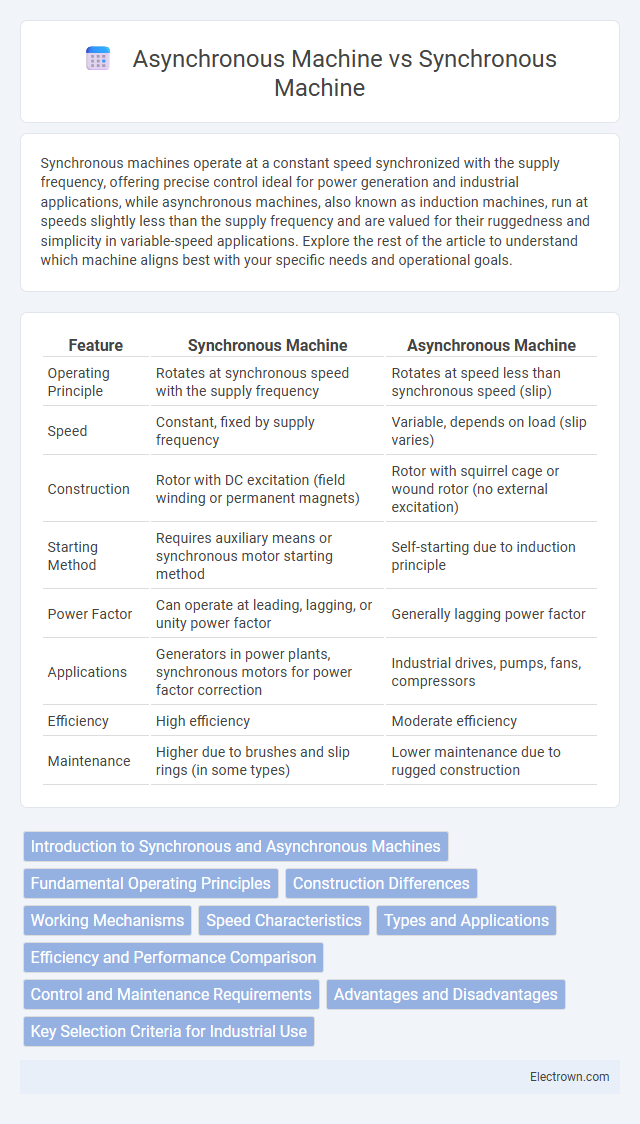

| Feature | Synchronous Machine | Asynchronous Machine |

|---|---|---|

| Operating Principle | Rotates at synchronous speed with the supply frequency | Rotates at speed less than synchronous speed (slip) |

| Speed | Constant, fixed by supply frequency | Variable, depends on load (slip varies) |

| Construction | Rotor with DC excitation (field winding or permanent magnets) | Rotor with squirrel cage or wound rotor (no external excitation) |

| Starting Method | Requires auxiliary means or synchronous motor starting method | Self-starting due to induction principle |

| Power Factor | Can operate at leading, lagging, or unity power factor | Generally lagging power factor |

| Applications | Generators in power plants, synchronous motors for power factor correction | Industrial drives, pumps, fans, compressors |

| Efficiency | High efficiency | Moderate efficiency |

| Maintenance | Higher due to brushes and slip rings (in some types) | Lower maintenance due to rugged construction |

Introduction to Synchronous and Asynchronous Machines

Synchronous machines operate at a constant speed directly proportional to the supply frequency, with the rotor's magnetic field synchronized with the stator's rotating magnetic field. Asynchronous machines, commonly known as induction motors, run at speeds slightly less than the synchronous speed, with rotor currents induced by electromagnetic induction. Understanding the fundamental differences between these machines helps optimize your choice for applications requiring precise speed control or robust, cost-effective operation.

Fundamental Operating Principles

Synchronous machines operate by rotating their magnetic field in sync with the stator's rotating magnetic field, maintaining a constant speed determined by the supply frequency. Asynchronous machines, or induction motors, rely on the relative speed difference (slip) between the rotor and stator magnetic fields to induce current and produce torque. The synchronous generator's rotor speed matches the stator's magnetic field frequency, whereas the asynchronous motor rotor speed is always slightly less than the synchronous speed, enabling electromagnetic induction.

Construction Differences

Synchronous machines feature a rotor with a permanent magnet or DC-excited electromagnet that rotates at a constant speed synchronized with the stator's rotating magnetic field. In contrast, asynchronous machines, commonly known as induction motors, have a rotor constructed with squirrel cage bars or wound coils that induce current from the stator field, causing it to rotate at a speed slightly less than the synchronous speed. The construction of synchronous machines requires slip rings and brushes for rotor excitation, whereas asynchronous machines typically have simpler rotor constructions without external excitation.

Working Mechanisms

Synchronous machines operate with a rotor speed that precisely matches the stator's rotating magnetic field, ensuring constant speed at synchronous frequency and often utilizing field windings energized by DC current. Asynchronous machines, also known as induction motors, function with a rotor that rotates at a speed slightly less than the stator's magnetic field, inducing current in the rotor through electromagnetic induction without the need for an external excitation source. Your choice between these machines depends on application requirements such as speed control precision and starting torque characteristics.

Speed Characteristics

Synchronous machines operate at a constant speed directly proportional to the supply frequency, allowing precise control in applications requiring fixed speed. Asynchronous machines, also known as induction machines, run at speeds slightly less than synchronous speed, with slip varying depending on load conditions. The fixed-speed characteristic of synchronous machines contrasts with the variable speed of asynchronous machines, influencing their selection for specific industrial uses.

Types and Applications

Synchronous machines include salient pole and cylindrical rotor types, commonly used in power generation and grid synchronization where constant speed is essential. Asynchronous machines, primarily squirrel cage and wound rotor types, dominate industrial applications such as pumps, fans, and conveyors due to their ruggedness and simple construction. The selection depends on performance needs; synchronous machines excel in precise speed control and reactive power management, while asynchronous machines offer cost-effective and maintenance-friendly operation.

Efficiency and Performance Comparison

Synchronous machines generally offer higher efficiency and better power factor control compared to asynchronous machines, making them ideal for applications requiring precise speed and voltage regulation. Asynchronous machines, also known as induction motors, tend to have lower initial costs and simpler construction but exhibit lower efficiency due to slip and higher rotor losses. Your choice depends on balancing efficiency needs against budget and performance requirements for specific industrial or commercial applications.

Control and Maintenance Requirements

Synchronous machines require precise control of excitation current to maintain constant speed and voltage stability, making their control systems more complex but enabling better power factor correction. Asynchronous machines rely on slip for operation, resulting in simpler control mechanisms but less efficiency in speed regulation and reactive power control. Maintenance of synchronous machines typically involves regular inspection of the excitation system and rotor position sensors, while asynchronous machines demand less rigorous upkeep due to their rugged construction and absence of brushes or slip rings.

Advantages and Disadvantages

Synchronous machines offer precise speed control and better efficiency under constant load, making them ideal for applications requiring exact synchronization with the grid. Asynchronous machines, or induction motors, are simpler, more robust, and cost-effective, but suffer from slip and reduced efficiency at varying loads. Your choice depends on the need for accuracy versus cost and maintenance considerations.

Key Selection Criteria for Industrial Use

Synchronous machines offer precise speed control and power factor correction, making them ideal for applications requiring constant speed and high efficiency, such as generators and heavy-duty industrial drives. Asynchronous machines, commonly known as induction motors, provide simplicity, robustness, and lower cost, which suits variable-speed operations and general-purpose industrial use. Your choice depends on factors like cost constraints, speed regulation needs, load characteristics, and maintenance capabilities.

Synchronous Machine vs Asynchronous Machine Infographic

electrown.com

electrown.com