Dual-inline packages (DIP) feature through-hole mounting with pins extending perpendicularly, offering easier manual soldering and prototyping, while surface-mount devices (SMD) are mounted directly on the PCB surface, allowing for more compact designs and automated assembly. Understanding the advantages of each can help you choose the best packaging type for your electronic project; read on to explore their applications and benefits in detail.

Table of Comparison

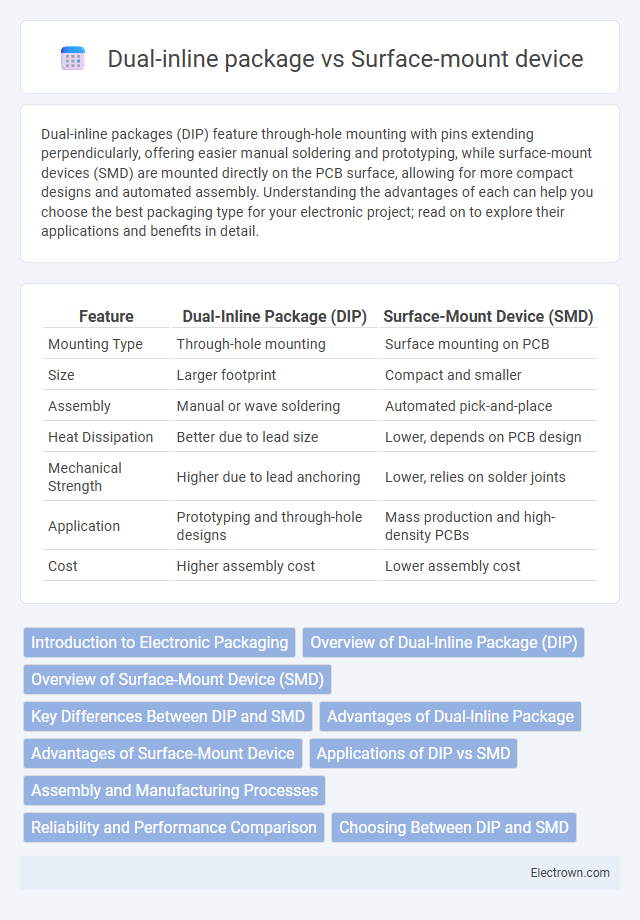

| Feature | Dual-Inline Package (DIP) | Surface-Mount Device (SMD) |

|---|---|---|

| Mounting Type | Through-hole mounting | Surface mounting on PCB |

| Size | Larger footprint | Compact and smaller |

| Assembly | Manual or wave soldering | Automated pick-and-place |

| Heat Dissipation | Better due to lead size | Lower, depends on PCB design |

| Mechanical Strength | Higher due to lead anchoring | Lower, relies on solder joints |

| Application | Prototyping and through-hole designs | Mass production and high-density PCBs |

| Cost | Higher assembly cost | Lower assembly cost |

Introduction to Electronic Packaging

Dual-inline package (DIP) offers through-hole mounting with leads extending from both sides to fit into circuit board holes, providing easy manual assembly and prototyping advantages. Surface-mount devices (SMD) feature compact, flat components soldered directly onto PCB surfaces, enabling higher component density and improved electrical performance. Electronic packaging choice influences manufacturing cost, assembly speed, thermal management, and overall device reliability in modern electronics.

Overview of Dual-Inline Package (DIP)

Dual-inline packages (DIPs) feature two parallel rows of pins extending perpendicularly from a rectangular housing, designed for through-hole mounting on printed circuit boards (PCBs). This packaging style facilitates easy manual insertion and soldering, making it ideal for prototyping and low-volume production. Your choice of DIP components provides reliable mechanical stability and straightforward replacement in electronic assemblies compared to surface-mount devices (SMDs).

Overview of Surface-Mount Device (SMD)

Surface-Mount Devices (SMD) are electronic components designed for direct placement onto the surface of printed circuit boards (PCBs), enabling higher circuit density and automated assembly processes. Unlike Dual Inline Packages (DIP), which have through-hole leads, SMDs feature smaller leads or no leads, allowing for reduced size and weight in electronic devices. This packaging technology supports faster manufacturing speeds, improved electrical performance, and enhanced mechanical reliability in modern electronics.

Key Differences Between DIP and SMD

Key differences between Dual-inline Package (DIP) and Surface-Mount Devices (SMD) include their physical mounting techniques and size; DIP components are through-hole mounted with leads inserted into holes on a printed circuit board (PCB), while SMDs are directly soldered onto the surface. DIP packages are generally larger, making them easier to handle and suitable for prototyping, whereas SMDs offer higher component density, better electrical performance, and enable more compact PCB designs. Your choice between DIP and SMD affects assembly methods, cost, and device performance depending on specific application requirements.

Advantages of Dual-Inline Package

Dual-Inline Package (DIP) offers ease of manual handling and soldering, making it ideal for prototyping and educational purposes. Its through-hole mounting provides stronger mechanical bonds on printed circuit boards (PCBs) compared to Surface-Mount Devices (SMDs). The larger size of DIPs allows for easier visual inspection and testing during assembly, reducing manufacturing errors.

Advantages of Surface-Mount Device

Surface-Mount Devices (SMDs) offer significant advantages over Dual-Inline Packages (DIP) by enabling higher circuit density and smaller PCB footprints, which supports miniaturization in modern electronics. Their automated assembly process reduces production time and costs while improving reliability through stronger mechanical bonds and lower parasitic inductance. Your electronic designs benefit from enhanced signal integrity and better performance in high-frequency applications by choosing SMD components.

Applications of DIP vs SMD

Dual-inline package (DIP) components are frequently used in prototyping, educational kits, and through-hole mounting applications where ease of manual insertion and soldering is essential. Surface-mount devices (SMD) dominate in high-density printed circuit boards (PCBs) for modern consumer electronics, telecommunications, and automotive systems due to their smaller size and suitability for automated assembly. DIP is preferred in applications requiring mechanical durability and easier replacement, whereas SMD is favored for mass production and compact designs with higher electrical performance.

Assembly and Manufacturing Processes

Dual-inline packages (DIP) require through-hole assembly, where component leads pass through PCB holes and are soldered on the opposite side, facilitating manual or wave soldering processes ideal for prototyping and low-volume production. Surface-mount devices (SMD) utilize automated pick-and-place machines and reflow soldering, enabling higher component density, faster assembly, and suitability for mass production with minimal manual intervention. The choice between DIP and SMD impacts line speed, manufacturing costs, and ease of inspection within electronic device fabrication.

Reliability and Performance Comparison

Dual-inline packages (DIP) generally offer higher mechanical robustness and easier manual inspection, resulting in strong reliability for through-hole mounting, especially in high-vibration environments. Surface-mount devices (SMD) provide superior electrical performance due to shorter lead lengths, enhancing signal integrity and enabling higher frequency operation. Your choice depends on balancing mechanical reliability demands with the performance benefits that SMD technology affords in compact, high-speed electronic designs.

Choosing Between DIP and SMD

Choosing between Dual-inline Package (DIP) and Surface-Mount Device (SMD) depends on factors like assembly method, space constraints, and rework ease. DIP components are preferred for prototyping and through-hole mounting on printed circuit boards (PCBs) due to their ease of manual handling and reliability in mechanical connections. SMD components offer higher component density and improved performance at smaller sizes, making them ideal for compact, automated assembly in modern electronic devices.

Dual-inline package vs surface-mount device Infographic

electrown.com

electrown.com