High-speed CAN offers faster data transmission rates up to 1 Mbps, ideal for time-sensitive automotive and industrial applications, while low-speed CAN provides reliable communication at rates up to 125 kbps, suitable for less critical or longer-distance networks. Explore the rest of the article to understand which CAN type best fits your system's needs and optimize your communication setup.

Table of Comparison

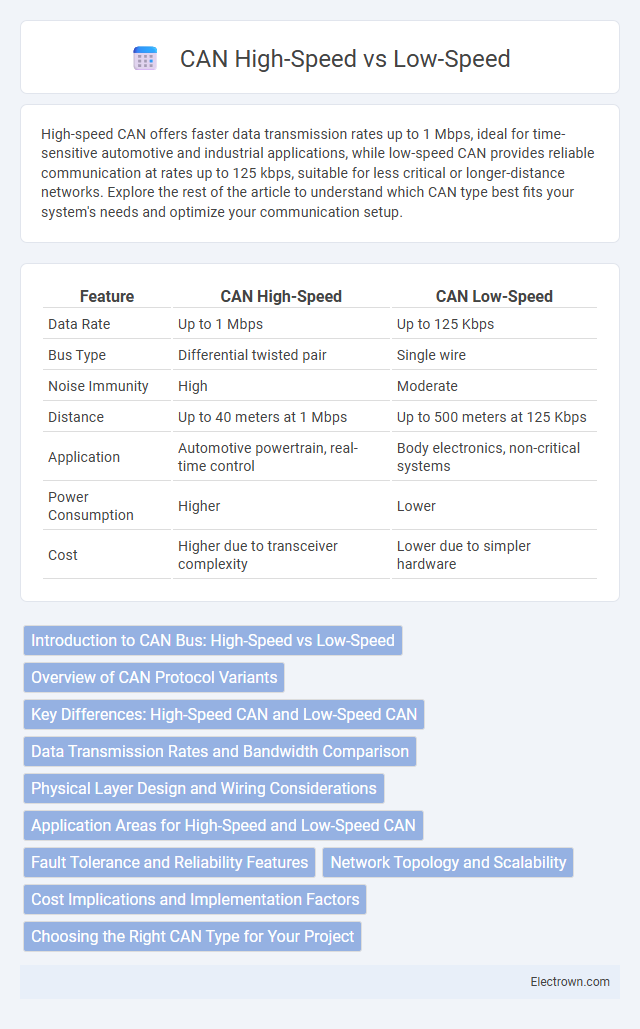

| Feature | CAN High-Speed | CAN Low-Speed |

|---|---|---|

| Data Rate | Up to 1 Mbps | Up to 125 Kbps |

| Bus Type | Differential twisted pair | Single wire |

| Noise Immunity | High | Moderate |

| Distance | Up to 40 meters at 1 Mbps | Up to 500 meters at 125 Kbps |

| Application | Automotive powertrain, real-time control | Body electronics, non-critical systems |

| Power Consumption | Higher | Lower |

| Cost | Higher due to transceiver complexity | Lower due to simpler hardware |

Introduction to CAN Bus: High-Speed vs Low-Speed

CAN High-Speed supports data rates up to 1 Mbps, making it ideal for real-time automotive and industrial communication where rapid data transfer and reliability are critical. CAN Low-Speed, operating at speeds up to 125 kbps, is suited for less time-sensitive applications with simpler wiring and reduced cost. Both use differential signaling for noise immunity, but High-Speed CAN features a dominant-recessive bit technique enabling faster and more robust data transmission.

Overview of CAN Protocol Variants

CAN High-Speed supports data rates up to 1 Mbps, enabling rapid communication in automotive and industrial applications, while CAN Low-Speed typically maxes out at 125 kbps for simpler networks requiring fault tolerance. Both variants use the same CAN protocol, including message arbitration and error detection, but differ in physical layer complexity and transmission speed. Choosing between CAN High-Speed and Low-Speed depends on system requirements such as bandwidth, cost, and environmental robustness.

Key Differences: High-Speed CAN and Low-Speed CAN

High-Speed CAN operates at data rates up to 1 Mbps and is designed for time-critical automotive applications requiring real-time communication, while Low-Speed CAN supports speeds up to 125 kbps and is typically used for non-critical functions such as window controls and seat adjustments. High-Speed CAN utilizes a differential signaling method for noise immunity over longer cable lengths, contrasting with Low-Speed CAN's single-wire, fault-tolerant design suitable for simpler wiring harnesses. Your choice between these two depends on the required data transmission speed, network complexity, and system safety requirements.

Data Transmission Rates and Bandwidth Comparison

CAN High-Speed supports data transmission rates up to 1 Mbps, offering a broader bandwidth suitable for time-critical automotive and industrial control applications. In contrast, CAN Low-Speed operates at a maximum of 125 kbps, providing reduced bandwidth typically used for non-critical, ignition-switched systems with lower data demands. The significant difference in data throughput positions CAN High-Speed for faster communication and CAN Low-Speed for cost-effective, simpler network implementations.

Physical Layer Design and Wiring Considerations

CAN High-Speed networks utilize a twisted pair wiring configuration supporting data rates up to 1 Mbps with differential signaling to ensure noise immunity and signal integrity over longer distances. CAN Low-Speed features a single-wire bus design, operating at lower speeds up to 125 kbps, often used for simple, shorter-distance applications where cost and wiring simplicity are prioritized. Your choice between High-Speed and Low-Speed CAN depends on the required data throughput, cable length, and electromagnetic noise environment, impacting the physical layer design and wiring considerations.

Application Areas for High-Speed and Low-Speed CAN

High-Speed CAN is commonly used in automotive applications requiring rapid data transmission, such as engine control units, antilock braking systems, and advanced driver-assistance systems, where fast and reliable communication is critical. Low-Speed CAN is typically found in body control modules, door and window motors, and interior lighting systems where data transfer speed is less critical but robustness and cost-effectiveness are prioritized. Your choice between High-Speed and Low-Speed CAN should depend on the specific application needs, balancing speed requirements and system complexity.

Fault Tolerance and Reliability Features

CAN High-Speed offers advanced fault tolerance with automatic retransmission and error detection mechanisms, making it ideal for critical automotive and industrial systems requiring high reliability. CAN Low-Speed provides basic fault tolerance suitable for less critical applications with lower data rates, incorporating simplified error detection and fault confinement features to ensure network stability. Your choice between the two should consider the required fault tolerance level and system reliability demands.

Network Topology and Scalability

CAN High-Speed networks utilize a twisted pair bus topology with termination resistors at both ends, enabling robust communication up to 1 Mbps and supporting longer cable lengths, making them ideal for scalable, complex automotive systems. CAN Low-Speed, also known as fault-tolerant CAN, employs a similar bus topology but operates at lower speeds up to 125 kbps, prioritizing fault tolerance over speed and suitable for smaller, less complex networks with limited scalability. Your choice between CAN High-Speed and Low-Speed affects the network's ability to grow and maintain performance across multiple nodes in automotive and industrial applications.

Cost Implications and Implementation Factors

CAN High-Speed offers faster data rates up to 1 Mbps, suitable for complex automotive systems but involves higher costs due to more advanced transceivers and shielding requirements. CAN Low-Speed operates at speeds up to 125 kbps, ideal for simpler sensor networks with lower cost components and easier implementation due to reduced electromagnetic interference concerns. Implementation factors include network length, node count, and environmental noise, where High-Speed is preferred for longer, more data-intensive networks, while Low-Speed suits shorter, cost-sensitive applications.

Choosing the Right CAN Type for Your Project

Selecting the appropriate CAN type depends on your project's speed and data priority requirements; CAN High-Speed supports up to 1 Mbps, ideal for applications demanding fast, reliable communication such as automotive or industrial control systems. CAN Low-Speed, operating at speeds up to 125 kbps, suits simpler, cost-sensitive environments like body electronics where fault tolerance and lower bandwidth suffice. Understanding these specifications ensures your project's efficiency, performance, and compatibility with existing hardware and protocols.

CAN High-Speed vs Low-Speed Infographic

electrown.com

electrown.com