CAN networks offer reliable, cost-effective communication for automotive systems but face limitations in bandwidth and scalability, while FlexRay provides higher data rates, deterministic timing, and fault tolerance for advanced vehicle applications. Explore the rest of the article to understand which protocol best suits your automotive communication needs.

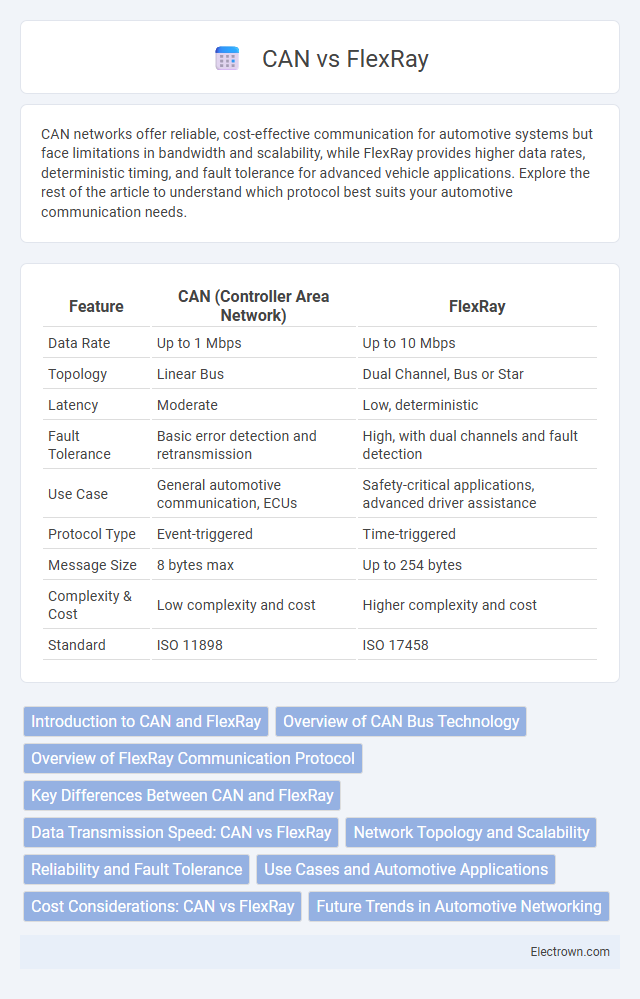

Table of Comparison

| Feature | CAN (Controller Area Network) | FlexRay |

|---|---|---|

| Data Rate | Up to 1 Mbps | Up to 10 Mbps |

| Topology | Linear Bus | Dual Channel, Bus or Star |

| Latency | Moderate | Low, deterministic |

| Fault Tolerance | Basic error detection and retransmission | High, with dual channels and fault detection |

| Use Case | General automotive communication, ECUs | Safety-critical applications, advanced driver assistance |

| Protocol Type | Event-triggered | Time-triggered |

| Message Size | 8 bytes max | Up to 254 bytes |

| Complexity & Cost | Low complexity and cost | Higher complexity and cost |

| Standard | ISO 11898 | ISO 17458 |

Introduction to CAN and FlexRay

Controller Area Network (CAN) is a robust vehicle bus standard designed for efficient communication among microcontrollers and devices without a host computer, widely used in automotive applications for its simplicity and real-time capabilities. FlexRay offers a higher data rate and deterministic timing, making it suitable for advanced automotive systems requiring fault tolerance and synchronization, such as drive-by-wire technology. Understanding the differences between CAN and FlexRay helps you select the right communication protocol for your vehicle's electronic control units (ECUs) based on speed, reliability, and complexity requirements.

Overview of CAN Bus Technology

CAN (Controller Area Network) bus technology is a robust vehicle bus standard designed for real-time communication between microcontrollers and devices without a host computer. It uses a multi-master, message-oriented protocol that allows multiple nodes to communicate simultaneously with error detection and fault confinement. Your automotive systems benefit from CAN's simplicity, cost-effectiveness, and widespread adoption in engine control, diagnostics, and body electronics.

Overview of FlexRay Communication Protocol

FlexRay is a high-speed automotive communication protocol designed for advanced driver assistance systems and in-vehicle networks, offering data rates up to 10 Mbps compared to CAN's 1 Mbps maximum. It uses time-triggered and event-triggered messaging with a dual-channel architecture to ensure deterministic, fault-tolerant communication and increased reliability in complex vehicle systems. FlexRay's synchronization mechanisms and scheduled data transmission provide greater bandwidth and reduced latency essential for real-time control applications.

Key Differences Between CAN and FlexRay

CAN (Controller Area Network) operates with a maximum data rate of 1 Mbps and uses message priority arbitration for collision management, making it suitable for simple automotive communication. FlexRay supports data rates up to 10 Mbps with time-triggered communication and dual-channel redundancy, providing higher reliability and deterministic timing for advanced vehicle systems. Your choice between CAN and FlexRay depends on system complexity, data rate requirements, and the need for fault tolerance in automotive networks.

Data Transmission Speed: CAN vs FlexRay

FlexRay supports data transmission speeds up to 10 Mbps, significantly outperforming the Controller Area Network (CAN) bus, which maxes out at 1 Mbps. The higher bandwidth of FlexRay enables reliable real-time communication for advanced automotive systems such as adaptive cruise control and stability management. CAN remains widely used for simpler control applications due to its robustness and lower cost, but FlexRay's speed advantage is critical for modern, high-performance vehicle networks.

Network Topology and Scalability

CAN bus employs a multi-master, broadcast network topology with a linear or star physical layout, supporting up to 1 Mbps data rates and a limited number of nodes, typically around 110, constrained by bus length and signal integrity. FlexRay utilizes a dual-channel, time-triggered network topology with static and dynamic segments, allowing for higher data rates up to 10 Mbps and enhanced scalability, supporting more nodes with fault tolerance and deterministic communication. This makes FlexRay suitable for complex automotive systems requiring synchronized and reliable data exchange across multiple ECUs.

Reliability and Fault Tolerance

FlexRay offers superior reliability and fault tolerance compared to CAN due to its dual-channel architecture that enables redundant data transmission, minimizing the risk of communication failure. CAN's single-channel design supports error detection through CRC checks and automatic retransmission but lacks the robustness for high-integrity systems requiring fail-safe operation. Your choice between CAN and FlexRay impacts system resilience, with FlexRay favored in safety-critical automotive and industrial applications demanding deterministic and fault-tolerant communication.

Use Cases and Automotive Applications

CAN (Controller Area Network) remains the standard communication protocol for real-time control systems in automotive applications such as engine management, powertrain, and body electronics due to its simplicity and cost-effectiveness. FlexRay offers higher bandwidth and deterministic data transmission, making it ideal for advanced driver-assistance systems (ADAS), autonomous driving, and safety-critical applications requiring fast and reliable communication. Automotive manufacturers increasingly integrate FlexRay alongside CAN to meet the demands of complex vehicle architectures and enhanced vehicle-to-vehicle communication systems.

Cost Considerations: CAN vs FlexRay

CAN networks offer significant cost advantages due to their simpler hardware requirements and widespread adoption, making them ideal for budget-conscious automotive applications. FlexRay, while more expensive because of its advanced communication protocols and higher bandwidth capabilities, provides superior performance for safety-critical systems where timing and fault tolerance are essential. Your choice between CAN and FlexRay should consider the balance between budget constraints and the need for robust, high-speed data transmission.

Future Trends in Automotive Networking

FlexRay offers higher bandwidth and deterministic data transmission, making it well-suited for future automotive applications such as advanced driver-assistance systems (ADAS) and autonomous driving, where low latency and reliability are critical. CAN remains dominant due to its simplicity and cost-effectiveness but is gradually complemented by Ethernet and FlexRay in complex vehicle architectures demanding increased data rates and real-time communication. Your choice of network technology will depend on the balance between cost, speed, and safety requirements as automotive networks evolve towards more integrated and intelligent systems.

CAN vs FlexRay Infographic

electrown.com

electrown.com