DIP (Dual In-line Package) components feature through-hole leads for easy manual soldering and prototyping, while SMD (Surface-Mount Device) components are designed for automated assembly with compact footprints ideal for high-density circuit boards. Explore the rest of the article to understand the advantages and applications of each to optimize your electronics design.

Table of Comparison

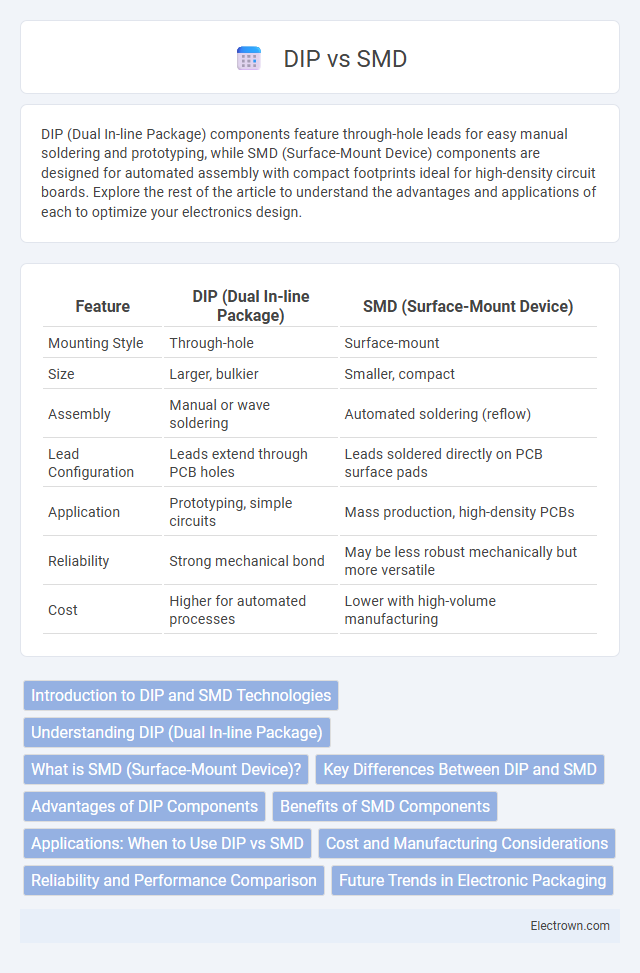

| Feature | DIP (Dual In-line Package) | SMD (Surface-Mount Device) |

|---|---|---|

| Mounting Style | Through-hole | Surface-mount |

| Size | Larger, bulkier | Smaller, compact |

| Assembly | Manual or wave soldering | Automated soldering (reflow) |

| Lead Configuration | Leads extend through PCB holes | Leads soldered directly on PCB surface pads |

| Application | Prototyping, simple circuits | Mass production, high-density PCBs |

| Reliability | Strong mechanical bond | May be less robust mechanically but more versatile |

| Cost | Higher for automated processes | Lower with high-volume manufacturing |

Introduction to DIP and SMD Technologies

DIP (Dual In-line Package) technology features through-hole components with two parallel rows of pins mounted on a PCB, offering ease of manual assembly and reliable mechanical connection. SMD (Surface-Mount Device) technology uses smaller components soldered directly onto the PCB surface, enabling higher component density and automated assembly. The shift from DIP to SMD reflects the electronics industry's push toward miniaturization and increased manufacturing efficiency.

Understanding DIP (Dual In-line Package)

DIP (Dual In-line Package) is a type of electronic component packaging characterized by two parallel rows of pins suitable for through-hole mounting on printed circuit boards (PCBs). DIP components are widely utilized in prototyping and hobbyist projects due to their ease of insertion and removal compared to surface-mount devices (SMD). Key advantages of DIP include straightforward manual handling, compatibility with breadboards and sockets, and enhanced mechanical stability in high-reliability applications.

What is SMD (Surface-Mount Device)?

SMD (Surface-Mount Device) refers to electronic components designed for surface-mount technology (SMT), where components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike DIP (Dual In-line Package) components, SMDs are smaller, allowing for higher component density and automated assembly processes that enhance manufacturing efficiency. Common SMD types include resistors, capacitors, and integrated circuits, which contribute to compact, lightweight, and high-performance electronic designs.

Key Differences Between DIP and SMD

DIP (Dual In-line Package) components feature through-hole leads designed for insertion into PCB holes, offering robust mechanical strength and ease of manual soldering. SMD (Surface-Mount Device) components are designed for mounting directly onto the PCB surface, enabling higher component density and suitability for automated assembly processes. Key differences include size, with SMD components being significantly smaller, and application methods, where DIP is favored for prototyping and repairs, while SMD is preferred for mass production and compact device design.

Advantages of DIP Components

DIP (Dual Inline Package) components offer easy handling and soldering, making them ideal for prototyping and manual assembly. Their through-hole design ensures stronger mechanical bonding to the PCB compared to surface-mount devices (SMD), enhancing durability in high-stress environments. You benefit from straightforward replacement and troubleshooting, which simplifies maintenance in your electronic projects.

Benefits of SMD Components

SMD components offer significant benefits, including smaller size and lighter weight, enabling higher component density on printed circuit boards (PCBs) and more compact device designs. Their automated assembly compatibility reduces production time and manufacturing costs while improving precision and reliability. Enhanced electrical performance and lower parasitic inductance make SMDs ideal for high-frequency applications, contributing to superior overall device efficiency.

Applications: When to Use DIP vs SMD

DIP (Dual In-line Package) components are preferred in prototyping, educational projects, and applications requiring manual soldering or easy replacement due to their larger size and through-hole mounting. SMD (Surface-Mount Device) components are ideal for high-density circuit designs, automated manufacturing, and applications demanding compact, lightweight, and high-frequency performance. Choosing between DIP and SMD depends on factors such as production volume, design complexity, repairability, and mechanical stability requirements.

Cost and Manufacturing Considerations

DIP (Dual Inline Package) components generally incur higher manufacturing costs due to their larger size and more complex through-hole assembly process compared to SMD (Surface Mount Device) components. SMD technology enables automated, high-speed placement and soldering on compact PCBs, significantly reducing labor and production expenses. Cost efficiency in mass production favors SMDs, while DIP remains preferred for prototyping and low-volume runs due to ease of manual handling.

Reliability and Performance Comparison

DIP (Dual In-line Package) components generally offer higher reliability in harsh environments due to their robust through-hole mounting, which provides better mechanical stability and heat dissipation compared to SMD (Surface-Mount Device) components. SMD components excel in performance with higher speed, lower parasitic inductance, and greater miniaturization, making them ideal for high-frequency and compact circuit designs. Your choice between DIP and SMD depends on the balance you need between mechanical durability and electrical performance in your specific application.

Future Trends in Electronic Packaging

Surface-Mount Devices (SMD) dominate future electronic packaging trends due to their smaller size, higher component density, and better thermal performance compared to Dual In-line Package (DIP). Advances in 3D packaging and System-in-Package (SiP) technologies further enhance SMD's integration capabilities, enabling more complex and compact electronic systems. Meanwhile, DIP packaging remains relevant for prototyping and through-hole mounting applications but is gradually being phased out in mass production environments.

DIP vs SMD Infographic

electrown.com

electrown.com