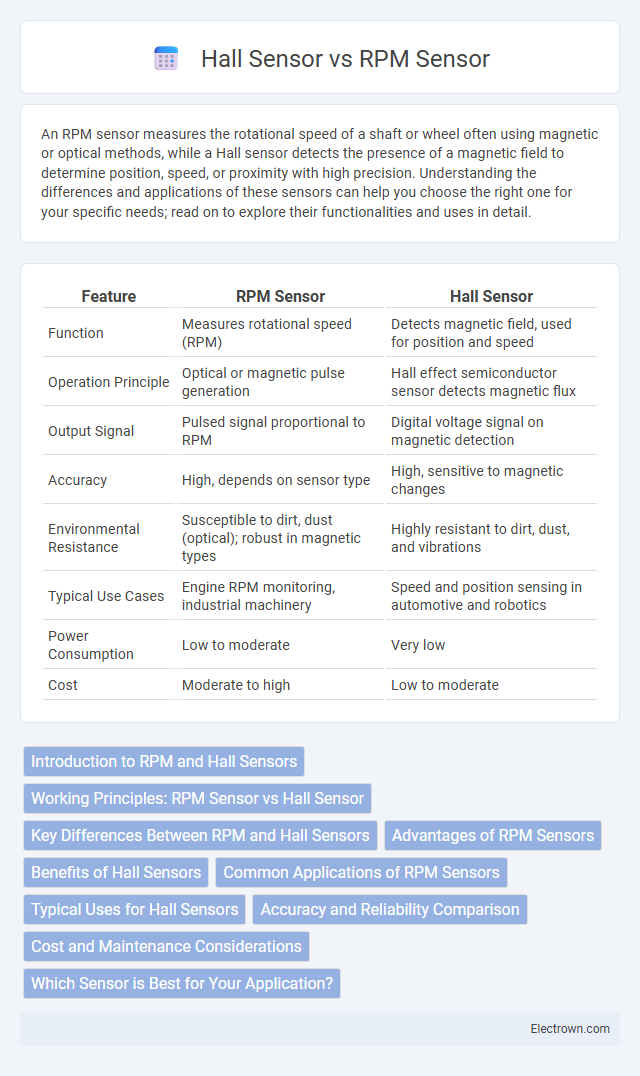

An RPM sensor measures the rotational speed of a shaft or wheel often using magnetic or optical methods, while a Hall sensor detects the presence of a magnetic field to determine position, speed, or proximity with high precision. Understanding the differences and applications of these sensors can help you choose the right one for your specific needs; read on to explore their functionalities and uses in detail.

Table of Comparison

| Feature | RPM Sensor | Hall Sensor |

|---|---|---|

| Function | Measures rotational speed (RPM) | Detects magnetic field, used for position and speed |

| Operation Principle | Optical or magnetic pulse generation | Hall effect semiconductor sensor detects magnetic flux |

| Output Signal | Pulsed signal proportional to RPM | Digital voltage signal on magnetic detection |

| Accuracy | High, depends on sensor type | High, sensitive to magnetic changes |

| Environmental Resistance | Susceptible to dirt, dust (optical); robust in magnetic types | Highly resistant to dirt, dust, and vibrations |

| Typical Use Cases | Engine RPM monitoring, industrial machinery | Speed and position sensing in automotive and robotics |

| Power Consumption | Low to moderate | Very low |

| Cost | Moderate to high | Low to moderate |

Introduction to RPM and Hall Sensors

RPM sensors measure the rotational speed of a shaft or component, providing critical data for engine control and diagnostic systems. Hall sensors detect magnetic field changes caused by rotating magnets or metal teeth, converting these signals into electrical pulses for precise speed and position tracking. Your choice between RPM and Hall sensors depends on accuracy, application environment, and integration requirements.

Working Principles: RPM Sensor vs Hall Sensor

RPM sensors typically operate using magnetic or optical methods to detect rotational speed by measuring the frequency of passing teeth or marks on a rotating object. Hall sensors function based on the Hall effect, generating a voltage when a magnetic field perpendicular to the sensor passes by, enabling precise detection of angular position or rotation. While RPM sensors often rely on changes in magnetic flux or light interruptions for speed measurement, Hall sensors provide direct electrical signals corresponding to magnetic field variations linked to rotation.

Key Differences Between RPM and Hall Sensors

RPM sensors measure rotational speed by detecting the frequency of signals generated from rotating objects, often using optical or magnetic methods, while Hall sensors detect the presence and strength of magnetic fields to determine position or speed. Hall sensors provide precise digital signals by reacting to changes in magnetic flux, making them durable and reliable in harsh environments. Your choice between RPM and Hall sensors depends on the specific application requirements, such as accuracy, environmental conditions, and signal type needed.

Advantages of RPM Sensors

RPM sensors provide precise rotational speed measurements essential for engine control and industrial automation. They operate effectively in harsh environments, offering high reliability and durability due to their non-contact measurement methods. Compared to Hall sensors, RPM sensors deliver faster response times and higher accuracy in detecting rapid speed changes.

Benefits of Hall Sensors

Hall sensors offer precise RPM measurement by detecting changes in magnetic fields, providing higher accuracy and reliability compared to traditional RPM sensors. Their non-contact operation reduces wear and maintenance needs, enhancing durability and performance in various automotive and industrial applications. Your systems can benefit from faster response times and better immunity to environmental contaminants, ensuring consistent and accurate RPM readings.

Common Applications of RPM Sensors

RPM sensors are commonly used in automotive engines, industrial machinery, and electric motors to monitor rotational speed for performance optimization and safety control. Hall sensors, a type of RPM sensor, are widely applied in brushless DC motors, anti-lock braking systems (ABS), and speedometers due to their precise magnetic field detection and durability. You can enhance your system's accuracy and reliability by selecting the appropriate RPM sensor based on the specific application's environmental and operational demands.

Typical Uses for Hall Sensors

Hall sensors are commonly used in automotive applications to measure the position and speed of rotating parts, such as crankshafts and camshafts, providing precise RPM data for engine control systems. They are also widely employed in brushless DC motors for speed detection and commutation control, ensuring efficient operation. Your choice of sensor can impact the accuracy and reliability of RPM measurements in industrial automation and robotics, where Hall sensors deliver non-contact sensing with high durability.

Accuracy and Reliability Comparison

RPM sensors typically offer high accuracy in measuring rotational speed by generating precise electrical pulses corresponding to shaft rotations, making them reliable for critical applications. Hall sensors, while slightly less precise due to magnetic field variations and potential interference, provide robust and consistent performance under harsh environments with fewer moving parts. Your choice depends on the required accuracy level and operating conditions, with RPM sensors excelling in precision-sensitive tasks and Hall sensors favored for durability and stability.

Cost and Maintenance Considerations

RPM sensors generally have lower upfront costs compared to Hall sensors, making them more economical for basic speed measurement applications. Hall sensors, while slightly more expensive, offer higher reliability and reduced maintenance needs due to their solid-state design and lack of mechanical wear. Choosing between the two depends on balancing initial investment against long-term durability and maintenance expenses.

Which Sensor is Best for Your Application?

Choosing between an RPM sensor and a Hall sensor depends on the specific application requirements such as accuracy, environmental conditions, and measurement type. RPM sensors, often optical or magnetic, provide direct rotational speed readings ideal for precise tachometer use, while Hall sensors detect magnetic field changes, offering robust, non-contact speed and position measurements suitable for harsh environments. Evaluating factors like response time, durability, and installation complexity helps determine the best sensor for automotive, industrial, or consumer electronics applications.

RPM sensor vs hall sensor Infographic

electrown.com

electrown.com