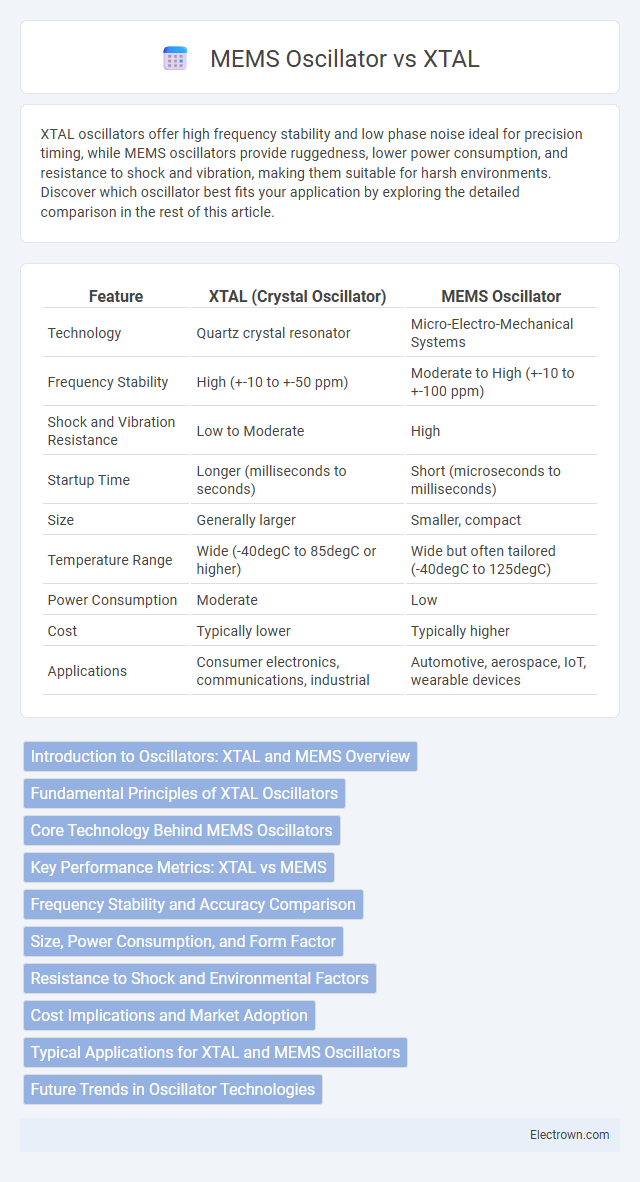

XTAL oscillators offer high frequency stability and low phase noise ideal for precision timing, while MEMS oscillators provide ruggedness, lower power consumption, and resistance to shock and vibration, making them suitable for harsh environments. Discover which oscillator best fits your application by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | XTAL (Crystal Oscillator) | MEMS Oscillator |

|---|---|---|

| Technology | Quartz crystal resonator | Micro-Electro-Mechanical Systems |

| Frequency Stability | High (+-10 to +-50 ppm) | Moderate to High (+-10 to +-100 ppm) |

| Shock and Vibration Resistance | Low to Moderate | High |

| Startup Time | Longer (milliseconds to seconds) | Short (microseconds to milliseconds) |

| Size | Generally larger | Smaller, compact |

| Temperature Range | Wide (-40degC to 85degC or higher) | Wide but often tailored (-40degC to 125degC) |

| Power Consumption | Moderate | Low |

| Cost | Typically lower | Typically higher |

| Applications | Consumer electronics, communications, industrial | Automotive, aerospace, IoT, wearable devices |

Introduction to Oscillators: XTAL and MEMS Overview

XTAL oscillators utilize quartz crystal resonators known for their high-frequency stability and precision in timing applications, making them ideal for clocks, communication devices, and microcontrollers. MEMS oscillators, based on microelectromechanical systems technology, offer enhanced shock resistance, miniaturization, and lower power consumption, suitable for mobile and IoT devices. Your choice between XTAL and MEMS oscillators depends on the required frequency stability, environmental robustness, and form factor constraints.

Fundamental Principles of XTAL Oscillators

XTAL oscillators rely on the piezoelectric effect of quartz crystals to generate highly stable and precise frequency signals by converting mechanical vibrations into electrical oscillations. The crystal's lattice structure resonates at a specific natural frequency, providing superior frequency accuracy and low phase noise compared to MEMS oscillators. These fundamental principles enable XTAL oscillators to excel in applications demanding stringent timing precision and long-term stability.

Core Technology Behind MEMS Oscillators

MEMS oscillators utilize microelectromechanical systems technology, where tiny mechanical resonators are fabricated on semiconductor chips, offering greater resistance to shock and vibration compared to traditional quartz crystal oscillators (XTAL). These resonators enable MEMS oscillators to achieve precise frequency stability, low phase noise, and miniaturized form factors, making them ideal for modern electronics requiring robust timing solutions. Your choice between XTAL and MEMS oscillators should consider the enhanced durability and integration capabilities provided by the core MEMS technology.

Key Performance Metrics: XTAL vs MEMS

XTAL oscillators provide superior frequency stability and low phase noise due to their quartz crystal resonators, making them ideal for applications requiring high precision and reliability. MEMS oscillators offer better shock resistance, smaller size, and faster startup times, while maintaining competitive frequency accuracy through microelectromechanical systems technology. Key performance metrics such as frequency stability (+-10 to +-50 ppm for MEMS vs. +-0.1 to +-10 ppb for XTAL), phase noise, and aging rates highlight the trade-offs between robustness and precision in choosing between XTAL and MEMS oscillators.

Frequency Stability and Accuracy Comparison

XTAL oscillators typically offer superior frequency stability with aging rates as low as +-1 ppm per year and temperature stability around +-0.5 ppm, making them highly reliable for precision timing applications. MEMS oscillators provide competitive accuracy, often ranging from +-10 ppm to +-50 ppm, but their frequency stability can vary more with temperature and environmental factors. The choice hinges on application requirements where XTAL excels in ultra-stable environments, while MEMS oscillators benefit from robustness and integration at the cost of slightly less frequency precision.

Size, Power Consumption, and Form Factor

MEMS oscillators offer significantly smaller size and more compact form factors compared to traditional XTAL oscillators, enabling integration in space-constrained applications like wearables and mobile devices. Power consumption of MEMS devices is generally lower due to their advanced semiconductor-based design, which enhances energy efficiency for battery-powered systems. XTAL oscillators remain favored for their superior frequency stability, but MEMS technology's advantages in miniaturization and reduced power make it ideal for modern low-power, high-density electronic designs.

Resistance to Shock and Environmental Factors

MEMS oscillators exhibit superior resistance to shock and environmental factors compared to traditional XTAL crystals, due to their solid-state silicon structures that can withstand high levels of mechanical stress without performance degradation. The inherent fragility of quartz crystals in XTAL oscillators makes them more susceptible to frequency shifts and failures under extreme temperature changes, humidity, and vibrations. MEMS technology also offers enhanced stability over a wider temperature range, making it ideal for harsh industrial and automotive applications where environmental resilience is critical.

Cost Implications and Market Adoption

XTAL oscillators generally offer lower initial costs due to simpler manufacturing processes and widespread adoption in traditional electronics markets. MEMS oscillators present higher upfront expenses but promise cost-efficiency in large-scale production through integration with silicon-based technologies. Your choice depends on balancing budget constraints with long-term market trends favoring MEMS adoption in modern, miniaturized devices.

Typical Applications for XTAL and MEMS Oscillators

XTAL oscillators are typically used in applications requiring high frequency stability and precision, such as telecommunications, GPS devices, and wristwatches. MEMS oscillators excel in environments demanding robustness and miniaturization, commonly found in automotive systems, aerospace, and portable consumer electronics. When choosing between the two, your application's tolerance for vibration, size constraints, and power consumption will determine the most suitable oscillator technology.

Future Trends in Oscillator Technologies

XTAL oscillators continue to offer unmatched frequency stability and low phase noise, making them ideal for precision applications, while MEMS oscillators provide enhanced resilience to shock, vibration, and temperature variations, promoting their adoption in mobile and automotive sectors. Emerging trends indicate a growing integration of MEMS technology with silicon-based processes, enabling smaller, lower-power oscillators suitable for IoT and 5G devices. Your choice between XTAL and MEMS oscillator technologies should consider upcoming needs for miniaturization, power efficiency, and environmental robustness in future electronic designs.

XTAL vs MEMS Oscillator Infographic

electrown.com

electrown.com