Timer Counter (TC) modules provide precise time measurement and event counting, while Pulse Width Modulation (PWM) generates variable duty cycle signals for controlling devices like motors and LEDs. Explore how understanding both concepts can enhance Your project's timing and control capabilities in the full article.

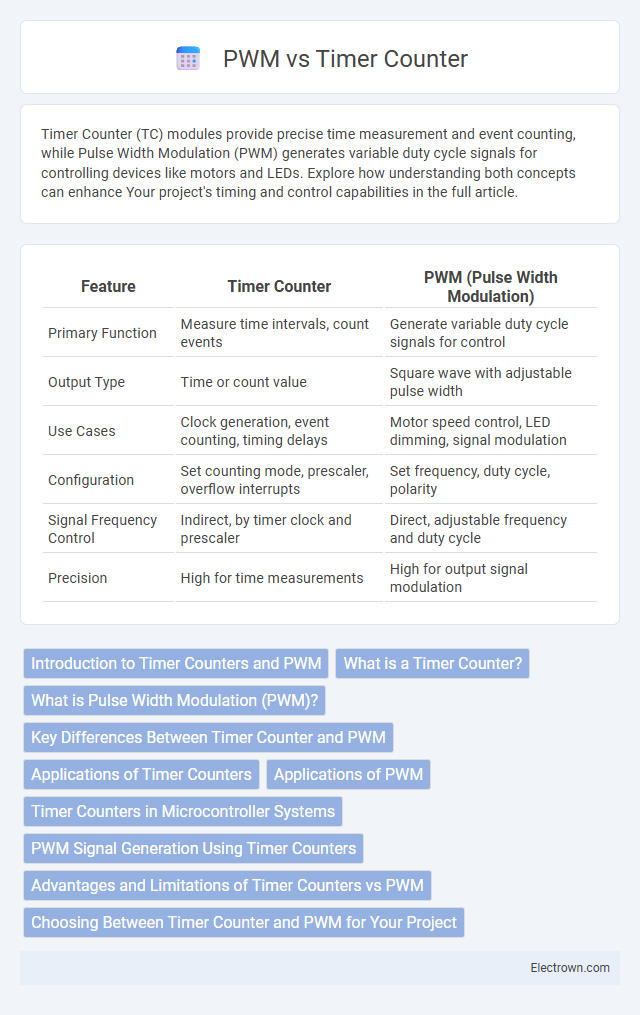

Table of Comparison

| Feature | Timer Counter | PWM (Pulse Width Modulation) |

|---|---|---|

| Primary Function | Measure time intervals, count events | Generate variable duty cycle signals for control |

| Output Type | Time or count value | Square wave with adjustable pulse width |

| Use Cases | Clock generation, event counting, timing delays | Motor speed control, LED dimming, signal modulation |

| Configuration | Set counting mode, prescaler, overflow interrupts | Set frequency, duty cycle, polarity |

| Signal Frequency Control | Indirect, by timer clock and prescaler | Direct, adjustable frequency and duty cycle |

| Precision | High for time measurements | High for output signal modulation |

Introduction to Timer Counters and PWM

Timer Counters are hardware modules within microcontrollers that measure time intervals and count events based on clock pulses, essential for precise time management in embedded systems. Pulse Width Modulation (PWM) uses Timer Counters to generate signals with variable duty cycles, controlling power delivery to devices such as motors and LEDs. Understanding how Timer Counters underpin PWM allows you to optimize signal timing and power control in your electronic projects.

What is a Timer Counter?

A Timer Counter is a microcontroller peripheral that counts clock pulses to measure time intervals or generate precise delays. It operates by incrementing a register value at a fixed frequency, enabling tasks like event counting, frequency measurement, and time-based interrupt generation. Timer Counters serve as the foundation for PWM (Pulse Width Modulation) signals by controlling signal timing and duty cycles in embedded systems.

What is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a technique that controls the amount of power delivered to an electrical device by varying the width of the pulses in a pulse train. It leverages Timer Counters within microcontrollers to generate precise on-off signals with adjustable duty cycles, enabling efficient management of motor speed, LED brightness, and other applications. Understanding PWM allows you to optimize your embedded system designs for energy efficiency and performance.

Key Differences Between Timer Counter and PWM

Timer Counter primarily measures time intervals and counts events, while PWM (Pulse Width Modulation) generates a variable duty cycle signal for controlling power delivery. Timer Counters operate by incrementing or decrementing counts based on clock pulses, useful for timing and event measurement, whereas PWM modulates signal duration to control devices like motors and LEDs. Key differences include Timer Counter's focus on precise counting and timekeeping versus PWM's role in signal modulation for analog control through digital means.

Applications of Timer Counters

Timer Counters are essential in embedded systems for measuring time intervals, generating precise delays, and counting events, making them ideal for applications such as real-time clocks, frequency measurement, and event counting. Unlike PWM, which primarily controls signal duty cycles for motor speed or LED dimming, Timer Counters provide accurate timing functions crucial for scheduling tasks and synchronizing processes. Your projects that require precise time tracking, stopwatch functionality, or periodic interrupts benefit significantly from the versatility of Timer Counters.

Applications of PWM

Pulse Width Modulation (PWM) finds extensive applications in motor speed control, LED brightness adjustment, and power delivery in electrical circuits due to its efficient modulation of signal power without energy waste. It enables precise control of the average voltage and current supplied to devices, making it ideal for use in battery-powered systems, audio signal generation, and digital-to-analog conversion. PWM's ability to provide variable power output with minimal heat generation is critical in embedded systems, robotics, and renewable energy applications such as solar inverter management.

Timer Counters in Microcontroller Systems

Timer Counters in microcontroller systems provide precise time measurement and event counting capabilities essential for task scheduling, frequency measurement, and generating accurate delays. Unlike PWM (Pulse Width Modulation), which primarily controls signal duty cycles for motor speed or LED brightness, Timer Counters monitor time intervals or count external events with high resolution. Your effective use of Timer Counters enhances real-time control and synchronization in embedded applications, ensuring accurate timing functions beyond simple signal modulation.

PWM Signal Generation Using Timer Counters

PWM signal generation using timer counters involves configuring timer modules to create precise duty cycles and frequencies by toggling output pins at specific intervals. Timer counters operate by counting clock pulses and resetting upon reaching a predefined value, enabling modulation of the signal's high and low states for effective pulse-width modulation. This method allows efficient control of motor speed, LED brightness, and other applications requiring variable power delivery through accurate PWM waveform synthesis.

Advantages and Limitations of Timer Counters vs PWM

Timer counters provide precise measurement and event-counting capabilities with high-resolution timing, making them ideal for applications requiring accurate time interval calculations or frequency measurement. PWM (Pulse Width Modulation) excels in efficiently controlling power delivery and motor speed by varying duty cycles, but it has limitations in timing precision and event counting compared to timer counters. While timer counters offer flexibility in timing functions, PWM is limited to output waveform generation and may introduce switching noise in sensitive circuits.

Choosing Between Timer Counter and PWM for Your Project

Selecting between Timer Counter and PWM depends on the specific requirements of your project, such as precision timing or output waveform control. Timer Counters excel in measuring time intervals and event counting, making them ideal for applications requiring accurate time tracking or frequency measurement. PWM stands out for controlling motor speed, LED brightness, and generating analog voltage levels through duty cycle modulation, offering efficient power management and signal control.

Timer Counter vs PWM Infographic

electrown.com

electrown.com