A flow meter measures the volume of fluid passing through a point over time, while a mass flow meter directly measures the mass of the fluid, offering greater accuracy in processes where fluid density varies. Discover how choosing the right type of flow meter can optimize your system's efficiency and accuracy by reading the rest of the article.

Table of Comparison

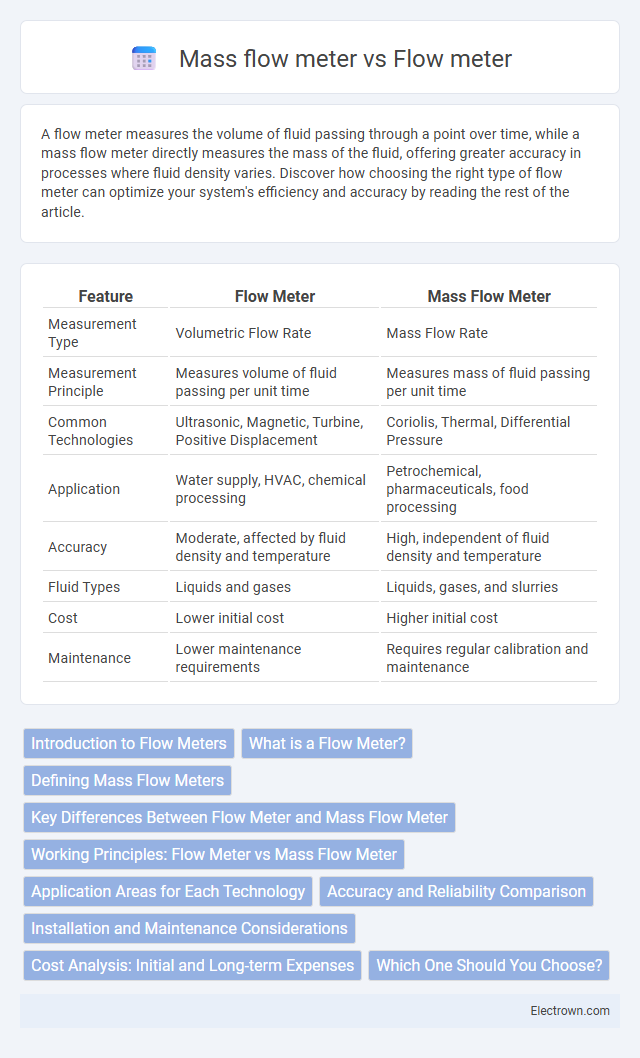

| Feature | Flow Meter | Mass Flow Meter |

|---|---|---|

| Measurement Type | Volumetric Flow Rate | Mass Flow Rate |

| Measurement Principle | Measures volume of fluid passing per unit time | Measures mass of fluid passing per unit time |

| Common Technologies | Ultrasonic, Magnetic, Turbine, Positive Displacement | Coriolis, Thermal, Differential Pressure |

| Application | Water supply, HVAC, chemical processing | Petrochemical, pharmaceuticals, food processing |

| Accuracy | Moderate, affected by fluid density and temperature | High, independent of fluid density and temperature |

| Fluid Types | Liquids and gases | Liquids, gases, and slurries |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Lower maintenance requirements | Requires regular calibration and maintenance |

Introduction to Flow Meters

Flow meters measure the volume or mass of fluid passing through a system, essential for process control and monitoring. Traditional flow meters gauge volumetric flow rates, often using mechanical or ultrasonic sensor technologies, while mass flow meters directly measure the mass flow using thermal or Coriolis principles, ensuring greater accuracy in varying temperature and pressure conditions. Understanding the differences helps you select the right flow meter for precise fluid measurement tailored to your application's needs.

What is a Flow Meter?

A flow meter measures the volume or velocity of a fluid moving through a pipe or conduit, providing essential data for process control and monitoring. Traditional flow meters typically measure volumetric flow rate, while mass flow meters directly quantify the mass of the fluid passing through, offering higher accuracy in varying temperature and pressure conditions. Understanding the distinction is crucial for selecting the appropriate device in industries such as oil and gas, chemical processing, and water treatment.

Defining Mass Flow Meters

Mass flow meters directly measure the mass rate of a fluid flowing through a pipe, providing accurate data vital for applications requiring precise mass flow measurement such as chemical processing and HVAC systems. Unlike traditional flow meters that measure volumetric flow, mass flow meters account for fluid density and composition, ensuring reliable readings regardless of temperature or pressure changes. Your choice of a mass flow meter enhances process control by delivering data critical for maintaining system efficiency and product quality.

Key Differences Between Flow Meter and Mass Flow Meter

Flow meters measure the volumetric flow rate of liquids or gases, typically in units such as gallons per minute (GPM) or cubic meters per hour (m3/h), while mass flow meters measure the actual mass of the fluid passing through, commonly in kilograms per second (kg/s) or pounds per hour (lb/h). Key differences include that mass flow meters are unaffected by changes in fluid density, temperature, or pressure, providing precise mass measurements essential for accurate process control. Your choice depends on whether measuring volume or mass is critical for your application's accuracy and consistency.

Working Principles: Flow Meter vs Mass Flow Meter

Flow meters measure the volumetric flow rate by detecting the velocity of a fluid passing through a pipe, using methods like differential pressure, turbine rotation, or ultrasonic signals. Mass flow meters, such as Coriolis or thermal flow meters, directly measure the mass of fluid flowing per unit time, providing higher accuracy for varying fluid densities and compositions. Your choice depends on whether you require volume or mass flow data, as mass flow meters compensate for temperature and pressure changes, ensuring precise flow measurement in critical applications.

Application Areas for Each Technology

Flow meters are widely used in water treatment, HVAC systems, and chemical processing for measuring volumetric flow rates, ensuring precise control of liquid and gas volumes. Mass flow meters dominate industries such as pharmaceuticals, food and beverage, and natural gas processing where accurate mass measurement is critical for process control and billing. Both technologies serve essential roles depending on the need for volume-based or mass-based flow measurement in industrial and commercial applications.

Accuracy and Reliability Comparison

Mass flow meters provide higher accuracy and reliability than traditional flow meters by directly measuring the mass of the fluid, eliminating errors caused by temperature, pressure, and density fluctuations. Flow meters, such as volumetric types, often require additional corrections to ensure precise readings, which can affect consistency in variable conditions. Your choice of a mass flow meter ensures dependable and precise flow measurement, especially in applications demanding tight process control.

Installation and Maintenance Considerations

Flow meters require careful alignment and proper positioning for accurate readings, often needing straight pipe runs before and after installation, while mass flow meters, like Coriolis or thermal types, are generally easier to install due to fewer requirements for straight pipe lengths and can measure flow directly without density corrections. Maintenance for traditional flow meters may involve recalibration and cleaning due to mechanical wear or buildup, whereas mass flow meters typically have fewer moving parts, resulting in lower maintenance needs and increased reliability. Your choice should consider the installation environment and maintenance capabilities to ensure optimal performance and longevity.

Cost Analysis: Initial and Long-term Expenses

Flow meters generally have lower initial costs compared to mass flow meters, making them a budget-friendly option for simple applications. However, mass flow meters often provide more accurate measurements and require less maintenance, potentially reducing long-term expenses and operational downtime. Your choice should weigh upfront investment against the benefits of precision and reliability for cost efficiency over time.

Which One Should You Choose?

Choosing between a flow meter and a mass flow meter depends on the specific requirements of your application, including the type of fluid and measurement accuracy needed. Flow meters measure volumetric flow rates, making them ideal for liquids and gases where volume is the critical parameter, while mass flow meters measure the mass flow rate, which is essential for precise process control in chemical, pharmaceutical, and food industries. Your choice should prioritize mass flow meters if you need accurate measurement regardless of fluid density or temperature changes.

Flow meter vs Mass flow meter Infographic

electrown.com

electrown.com