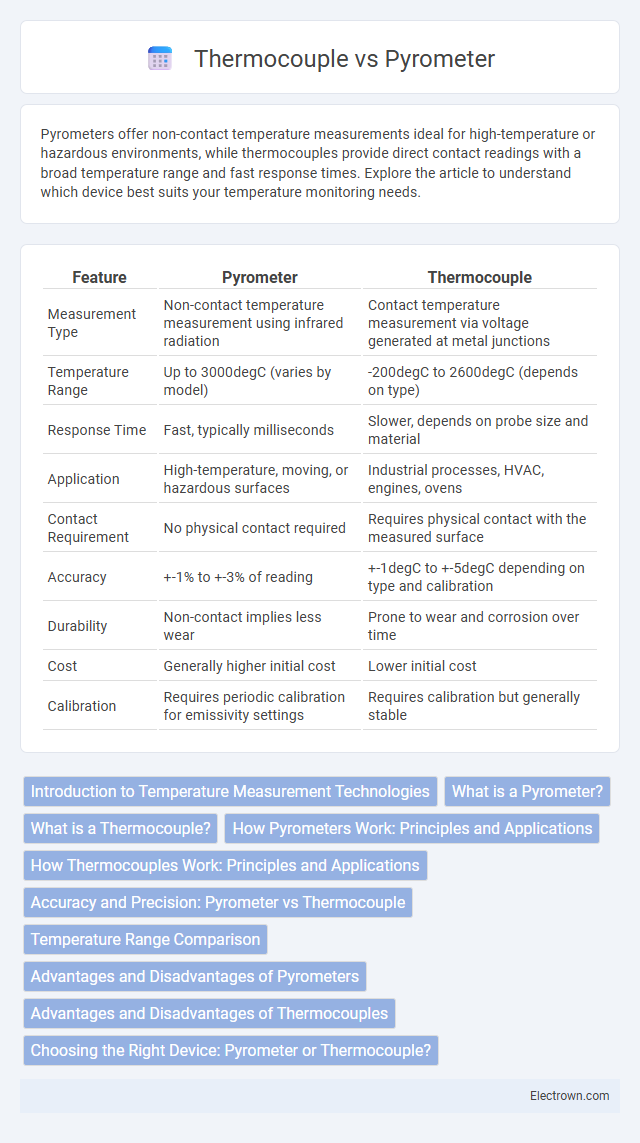

Pyrometers offer non-contact temperature measurements ideal for high-temperature or hazardous environments, while thermocouples provide direct contact readings with a broad temperature range and fast response times. Explore the article to understand which device best suits your temperature monitoring needs.

Table of Comparison

| Feature | Pyrometer | Thermocouple |

|---|---|---|

| Measurement Type | Non-contact temperature measurement using infrared radiation | Contact temperature measurement via voltage generated at metal junctions |

| Temperature Range | Up to 3000degC (varies by model) | -200degC to 2600degC (depends on type) |

| Response Time | Fast, typically milliseconds | Slower, depends on probe size and material |

| Application | High-temperature, moving, or hazardous surfaces | Industrial processes, HVAC, engines, ovens |

| Contact Requirement | No physical contact required | Requires physical contact with the measured surface |

| Accuracy | +-1% to +-3% of reading | +-1degC to +-5degC depending on type and calibration |

| Durability | Non-contact implies less wear | Prone to wear and corrosion over time |

| Cost | Generally higher initial cost | Lower initial cost |

| Calibration | Requires periodic calibration for emissivity settings | Requires calibration but generally stable |

Introduction to Temperature Measurement Technologies

Temperature measurement technologies include pyrometers and thermocouples, each utilizing different principles to monitor heat accurately. Pyrometers measure temperature remotely by detecting thermal radiation emitted by an object, ideal for high-temperature or inaccessible environments. Thermocouples are contact sensors that generate voltage based on temperature differences between metal junctions, providing precise and direct temperature readings for various industrial applications.

What is a Pyrometer?

A pyrometer is a non-contact temperature measurement device that uses infrared radiation emitted by an object to determine its temperature accurately. Unlike thermocouples, which require physical contact to measure heat through electrical voltage, pyrometers enable measurement of high temperatures from a distance, making them ideal for hazardous or moving objects. Your choice of a pyrometer ensures precise temperature readings in environments where contact sensors like thermocouples are impractical or unsafe.

What is a Thermocouple?

A thermocouple is a temperature sensor consisting of two different metal wires joined at one end, generating a voltage proportional to the temperature difference between the joined end and the other ends. Unlike a pyrometer, which measures temperature remotely using infrared radiation, a thermocouple requires direct contact with the object to provide precise temperature readings. Your choice between a thermocouple and a pyrometer depends on factors like measurement range, environment, and response time.

How Pyrometers Work: Principles and Applications

Pyrometers measure temperature by detecting the infrared radiation emitted by an object, relying on the principle that all objects emit thermal radiation proportional to their temperature. Unlike thermocouples, which require direct contact to measure temperature through voltage generated at the junction of two metals, pyrometers provide non-contact temperature readings ideal for moving, hazardous, or high-temperature surfaces. Your choice of pyrometer or thermocouple should depend on factors such as the required temperature range, measurement environment, and response time.

How Thermocouples Work: Principles and Applications

Thermocouples work on the principle of the Seebeck effect, where two dissimilar metals joined at one end generate a voltage proportional to the temperature difference between the junction and the reference end, allowing precise temperature measurements. Widely used in industrial applications, thermocouples measure extreme temperatures in furnaces, engines, and manufacturing processes due to their durability and fast response time. Your choice between a pyrometer and a thermocouple depends on the need for contact or non-contact temperature measurement and the specific environmental conditions.

Accuracy and Precision: Pyrometer vs Thermocouple

Pyrometers offer high accuracy in non-contact temperature measurements, especially at elevated temperatures, with precision dependent on sensor quality and environmental factors. Thermocouples provide reliable accuracy across a broad temperature range but may require calibration to maintain precision during extended use. Your choice between pyrometer and thermocouple should consider the required measurement environment and precision needs for optimal results.

Temperature Range Comparison

Pyrometers typically measure high temperatures ranging from 500degC to over 3000degC, making them ideal for non-contact measurements in extreme heat environments such as furnaces and molten metal. Thermocouples cover a broader temperature range, from approximately -200degC up to 1800degC depending on the type (e.g., Type K, Type J), offering versatility for both low and high-temperature applications. Selection between pyrometers and thermocouples depends on required temperature range accuracy, environmental conditions, and measurement contact preferences.

Advantages and Disadvantages of Pyrometers

Pyrometers offer non-contact temperature measurement, making them ideal for monitoring high-temperature objects or hazardous environments where thermocouples cannot be safely placed. They provide fast response times and require minimal maintenance, but their accuracy can be affected by surface emissivity and environmental conditions like dust or smoke. Your choice depends on whether you prioritize non-intrusive measurement and speed over the typically broader temperature range and durability of thermocouples.

Advantages and Disadvantages of Thermocouples

Thermocouples offer high-temperature measurement capabilities up to 2300degC, making them ideal for industrial applications requiring durability and fast response times. However, they can suffer from accuracy drift over time and may require frequent calibration to maintain precision. Your choice of temperature sensor should consider these trade-offs between cost-effectiveness and measurement stability.

Choosing the Right Device: Pyrometer or Thermocouple?

Choosing between a pyrometer and a thermocouple depends on your specific temperature measurement needs and the environment. Pyrometers are ideal for non-contact, high-temperature measurements in hazardous or hard-to-reach areas, offering fast response with minimal interference. Thermocouples provide accurate contact temperature readings across a wide range, suitable for direct measurement in industrial and scientific applications where sensor placement is feasible.

Pyrometer vs Thermocouple Infographic

electrown.com

electrown.com