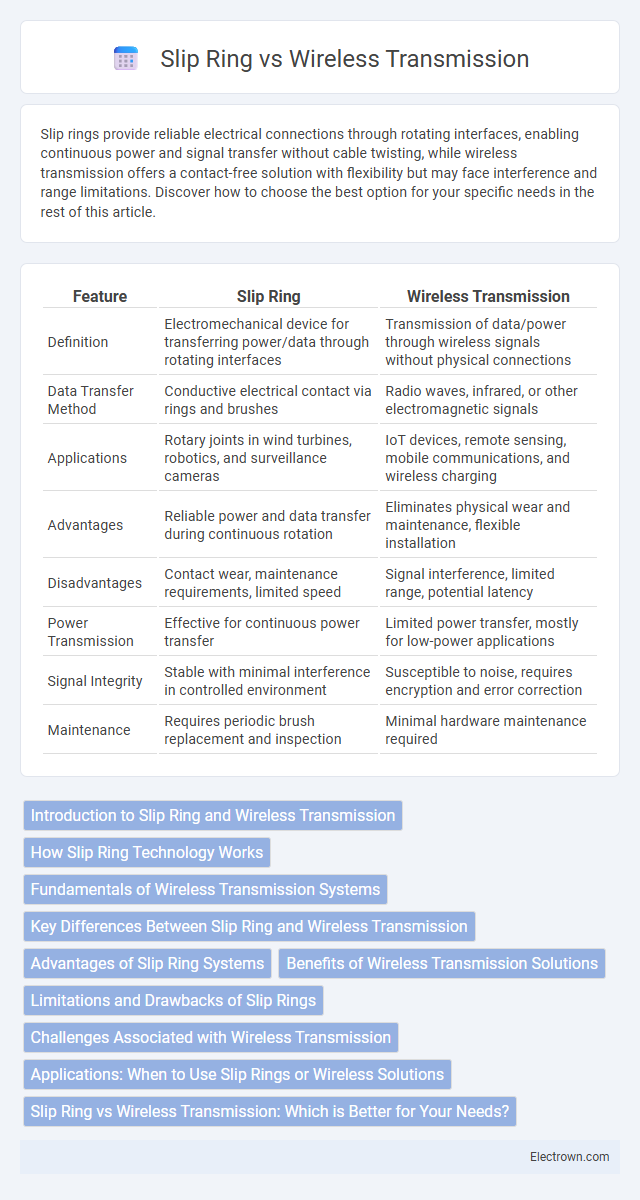

Slip rings provide reliable electrical connections through rotating interfaces, enabling continuous power and signal transfer without cable twisting, while wireless transmission offers a contact-free solution with flexibility but may face interference and range limitations. Discover how to choose the best option for your specific needs in the rest of this article.

Table of Comparison

| Feature | Slip Ring | Wireless Transmission |

|---|---|---|

| Definition | Electromechanical device for transferring power/data through rotating interfaces | Transmission of data/power through wireless signals without physical connections |

| Data Transfer Method | Conductive electrical contact via rings and brushes | Radio waves, infrared, or other electromagnetic signals |

| Applications | Rotary joints in wind turbines, robotics, and surveillance cameras | IoT devices, remote sensing, mobile communications, and wireless charging |

| Advantages | Reliable power and data transfer during continuous rotation | Eliminates physical wear and maintenance, flexible installation |

| Disadvantages | Contact wear, maintenance requirements, limited speed | Signal interference, limited range, potential latency |

| Power Transmission | Effective for continuous power transfer | Limited power transfer, mostly for low-power applications |

| Signal Integrity | Stable with minimal interference in controlled environment | Susceptible to noise, requires encryption and error correction |

| Maintenance | Requires periodic brush replacement and inspection | Minimal hardware maintenance required |

Introduction to Slip Ring and Wireless Transmission

Slip rings enable continuous electrical power and signal transfer between stationary and rotating components, making them essential in rotating machinery. Wireless transmission uses radio waves or electromagnetic fields to send data or power without physical connections, ideal for eliminating mechanical wear and increasing flexibility. Your choice between slip ring and wireless transmission depends on factors like power requirements, signal integrity, and environmental conditions.

How Slip Ring Technology Works

Slip ring technology operates by using rotating conductive rings and stationary brushes to transmit electrical signals or power across a rotating interface, enabling continuous energy or data transfer without cable twisting. The slip ring consists of multiple conductive rings fixed to a rotating shaft and corresponding stationary brushes that maintain contact to allow current flow. This mechanical contact ensures reliable transmission for applications such as wind turbines, robotics, and radar systems where rotational movement is essential.

Fundamentals of Wireless Transmission Systems

Wireless transmission systems use electromagnetic waves to transmit data without physical connectors, offering higher flexibility and eliminating wear issues common in slip rings. These systems rely on antennas, modulators, and demodulators to convert electrical signals into radio waves and back, enabling seamless communication over varying distances. Your choice between slip rings and wireless transmission depends on factors like data rate requirements, environmental conditions, and maintenance considerations.

Key Differences Between Slip Ring and Wireless Transmission

Slip rings provide continuous electrical connection for rotating equipment using physical contacts, whereas wireless transmission relies on electromagnetic waves for contactless data or power transfer. Slip rings excel in high power and real-time signal applications but are prone to wear and require maintenance, while wireless transmission offers flexibility and reduces mechanical wear but can face interference and limited range issues. The choice depends on factors such as power requirements, signal integrity, environmental conditions, and system complexity.

Advantages of Slip Ring Systems

Slip ring systems provide continuous and reliable electrical connections for rotating equipment, enabling efficient power and signal transmission without interruption. They offer high durability, capable of handling high current loads and harsh environments, making them ideal for industrial machinery and wind turbines. Your operations benefit from minimal maintenance requirements and precise data transfer, ensuring optimal performance in applications requiring consistent rotation.

Benefits of Wireless Transmission Solutions

Wireless transmission solutions eliminate physical wear and tear issues associated with slip rings, ensuring longer equipment lifespan and reduced maintenance costs. They offer seamless data and power transfer across rotating or moving parts without the constraints of mechanical contact, enhancing system reliability and operational flexibility. Your operations can benefit from increased precision and reduced downtime, supporting advanced industrial and robotic applications.

Limitations and Drawbacks of Slip Rings

Slip rings face limitations such as mechanical wear, which leads to maintenance needs and reduced lifespan due to friction between contacts. Their performance can degrade under harsh environmental conditions like dust, moisture, and vibration, causing signal interference or loss. Wireless transmission avoids these drawbacks by eliminating physical contact, offering greater flexibility and reliability for Your rotating systems.

Challenges Associated with Wireless Transmission

Wireless transmission faces significant challenges such as signal interference, limited range, and bandwidth constraints, which can impact data integrity and communication reliability. Environmental factors like obstacles and electromagnetic noise further degrade wireless performance, making consistent operation difficult in industrial settings. Your choice between wireless transmission and slip rings should consider these limitations to ensure seamless connectivity and system efficiency.

Applications: When to Use Slip Rings or Wireless Solutions

Slip rings are ideal for applications requiring continuous rotation with electrical power or signal transmission, such as wind turbines, robotics, and radar systems. Wireless transmission suits scenarios needing contactless data transfer or where physical connections are impractical, including wearable devices, remote sensors, and automotive telemetry. Your choice depends on factors like rotational speed, environmental conditions, and signal type to ensure reliable performance.

Slip Ring vs Wireless Transmission: Which is Better for Your Needs?

Slip ring systems provide reliable, continuous electrical transmission in rotating applications with minimal signal loss, ideal for high-torque machinery and industrial equipment requiring stable power and data transfer. Wireless transmission offers flexibility, ease of installation, and reduced maintenance by eliminating physical connections, best suited for applications needing mobility or where wiring is impractical but may face interference and limited data rates. Evaluating factors such as environmental conditions, transmission distance, data integrity, and maintenance capabilities helps determine whether slip rings or wireless transmission better align with specific operational requirements.

Slip ring vs Wireless transmission Infographic

electrown.com

electrown.com