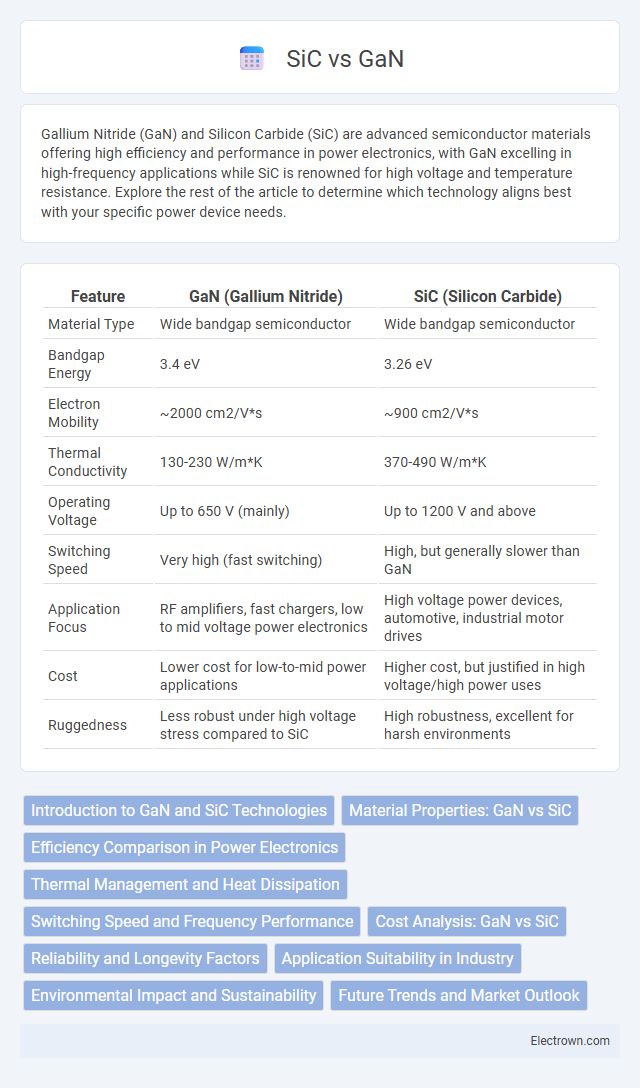

Gallium Nitride (GaN) and Silicon Carbide (SiC) are advanced semiconductor materials offering high efficiency and performance in power electronics, with GaN excelling in high-frequency applications while SiC is renowned for high voltage and temperature resistance. Explore the rest of the article to determine which technology aligns best with your specific power device needs.

Table of Comparison

| Feature | GaN (Gallium Nitride) | SiC (Silicon Carbide) |

|---|---|---|

| Material Type | Wide bandgap semiconductor | Wide bandgap semiconductor |

| Bandgap Energy | 3.4 eV | 3.26 eV |

| Electron Mobility | ~2000 cm2/V*s | ~900 cm2/V*s |

| Thermal Conductivity | 130-230 W/m*K | 370-490 W/m*K |

| Operating Voltage | Up to 650 V (mainly) | Up to 1200 V and above |

| Switching Speed | Very high (fast switching) | High, but generally slower than GaN |

| Application Focus | RF amplifiers, fast chargers, low to mid voltage power electronics | High voltage power devices, automotive, industrial motor drives |

| Cost | Lower cost for low-to-mid power applications | Higher cost, but justified in high voltage/high power uses |

| Ruggedness | Less robust under high voltage stress compared to SiC | High robustness, excellent for harsh environments |

Introduction to GaN and SiC Technologies

Gallium Nitride (GaN) and Silicon Carbide (SiC) are advanced semiconductor materials revolutionizing power electronics with superior efficiency and thermal performance compared to traditional silicon. GaN excels in high-frequency, high-electron-mobility applications, making it ideal for RF amplifiers and fast-switching power devices, while SiC offers exceptional durability and efficiency for high-voltage, high-temperature environments such as electric vehicles and industrial power converters. These wide bandgap semiconductors enable higher power density, faster switching speeds, and improved thermal management, driving innovations in energy-efficient systems and compact power solutions.

Material Properties: GaN vs SiC

Gallium Nitride (GaN) offers higher electron mobility and critical electric field strength compared to Silicon Carbide (SiC), enabling faster switching speeds and greater efficiency in high-frequency applications. SiC exhibits superior thermal conductivity and mechanical robustness, making it highly suitable for high-power and high-temperature environments. Both materials are wide-bandgap semiconductors, but GaN's lower on-resistance and faster electron saturation velocity make it ideal for compact power devices, whereas SiC's durability ensures long-term reliability in heavy-duty applications.

Efficiency Comparison in Power Electronics

Gallium Nitride (GaN) devices exhibit higher efficiency than Silicon Carbide (SiC) in power electronics due to their superior electron mobility and lower on-resistance, which reduces conduction losses. GaN transistors operate at higher frequencies and temperatures, enabling smaller passive components and improved overall system efficiency. SiC, while slightly less efficient in switching speed, offers better performance under high-voltage and high-current conditions, making it suitable for heavy-duty applications.

Thermal Management and Heat Dissipation

GaN (Gallium Nitride) devices offer superior thermal conductivity compared to SiC (Silicon Carbide), enabling more efficient heat dissipation in high-power applications. While SiC can withstand higher junction temperatures, GaN's ability to operate at lower thermal resistance reduces the need for bulky cooling systems, enhancing your device's overall thermal management. Optimizing thermal pathways with GaN can significantly improve performance and longevity in compact electronic designs.

Switching Speed and Frequency Performance

GaN (Gallium Nitride) devices outperform SiC (Silicon Carbide) in switching speed due to their higher electron mobility and lower gate charge, enabling operations at frequencies exceeding several MHz. SiC devices exhibit robust high-voltage handling and thermal stability but typically switch at lower frequencies compared to GaN, making GaN ideal for applications demanding ultra-fast switching. Your choice between GaN and SiC should consider the required switching frequency and efficiency, with GaN preferred for high-frequency solutions.

Cost Analysis: GaN vs SiC

Gallium Nitride (GaN) devices generally offer lower material and manufacturing costs compared to Silicon Carbide (SiC) due to simpler substrate production and higher wafer yields. However, SiC components tend to provide superior thermal performance and durability, which can justify their higher upfront expenses in high-power, high-temperature applications. You can optimize your investment by selecting GaN for cost-sensitive, high-frequency uses and SiC where robustness and efficiency under extreme conditions are critical.

Reliability and Longevity Factors

GaN (Gallium Nitride) devices exhibit superior switching speed and efficiency but face challenges in thermal management that can impact long-term reliability compared to SiC (Silicon Carbide), which offers robust thermal conductivity and higher breakdown voltage, enhancing device longevity in harsh environments. SiC components maintain stable performance under high temperatures and electrical stress, making them ideal for applications requiring durable and reliable power electronics. Your choice between GaN and SiC should consider the specific operational conditions and lifecycle demands for optimal reliability.

Application Suitability in Industry

GaN (Gallium Nitride) excels in high-frequency, high-efficiency power electronics ideal for communication infrastructure and fast-charging devices, while SiC (Silicon Carbide) offers superior thermal performance and robustness suited for heavy-duty industrial applications like electric vehicle powertrains and renewable energy systems. Your choice depends on whether your industry prioritizes high-speed switching and miniaturization with GaN or high-temperature endurance and durability with SiC. Both materials significantly enhance energy efficiency and reliability across various industrial power electronic applications.

Environmental Impact and Sustainability

GaN (Gallium Nitride) devices generally offer higher energy efficiency and smaller device sizes compared to SiC (Silicon Carbide), reducing material usage and operational energy consumption, which lowers overall environmental impact. SiC, with its robustness and high thermal conductivity, supports longer device lifespans and better thermal management, contributing to sustainability by minimizing waste and improving energy efficiency in high-power applications. Your choice between GaN and SiC should consider the specific application's environmental goals, balancing efficiency, durability, and lifecycle impact for optimal sustainability outcomes.

Future Trends and Market Outlook

Gallium Nitride (GaN) and Silicon Carbide (SiC) technologies are poised for significant growth driven by increasing demand in electric vehicles, renewable energy, and 5G infrastructure. GaN is preferred for high-frequency applications and efficiency, while SiC excels in high-power and high-temperature environments, shaping distinct market niches. Forecasts predict a CAGR exceeding 20% for both semiconductors, with global GaN market valuation expected to surpass $4 billion by 2028 and SiC market reaching $10 billion due to advancements in power electronics and automotive sectors.

GaN vs SiC Infographic

electrown.com

electrown.com