PMICs integrate multiple power management functions into a single chip, offering improved efficiency, reduced board space, and simplified design compared to discrete components that require individual management and connections. Discover how choosing between PMICs and discrete components can impact your device's performance and design by reading the full article.

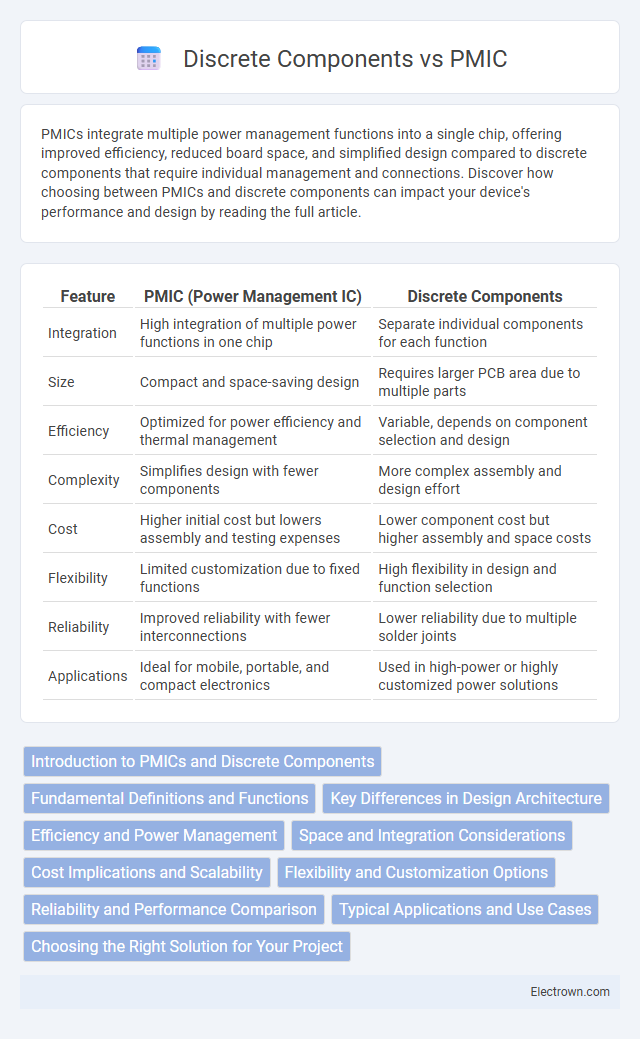

Table of Comparison

| Feature | PMIC (Power Management IC) | Discrete Components |

|---|---|---|

| Integration | High integration of multiple power functions in one chip | Separate individual components for each function |

| Size | Compact and space-saving design | Requires larger PCB area due to multiple parts |

| Efficiency | Optimized for power efficiency and thermal management | Variable, depends on component selection and design |

| Complexity | Simplifies design with fewer components | More complex assembly and design effort |

| Cost | Higher initial cost but lowers assembly and testing expenses | Lower component cost but higher assembly and space costs |

| Flexibility | Limited customization due to fixed functions | High flexibility in design and function selection |

| Reliability | Improved reliability with fewer interconnections | Lower reliability due to multiple solder joints |

| Applications | Ideal for mobile, portable, and compact electronics | Used in high-power or highly customized power solutions |

Introduction to PMICs and Discrete Components

Power Management Integrated Circuits (PMICs) consolidate multiple power functions into a single chip, optimizing efficiency and saving board space compared to discrete components, which are individual devices like regulators, capacitors, and inductors performing separate power tasks. PMICs simplify design complexity and improve reliability by integrating voltage regulation, battery management, and power sequencing, while discrete components offer flexibility and customization for specific applications. Understanding the differences between PMICs and discrete components helps you select the most effective power management approach for your electronic design.

Fundamental Definitions and Functions

Power Management Integrated Circuits (PMICs) are specialized chips designed to manage power requirements for electronic devices by integrating multiple power functions such as voltage regulation, battery charging, and power sequencing into a single package. Discrete components consist of separate individual elements like regulators, transistors, and capacitors that each perform a specific power management function independently. You benefit from PMICs' compactness and efficiency when managing complex power needs, while discrete components offer flexibility and customization for specific applications.

Key Differences in Design Architecture

PMICs (Power Management Integrated Circuits) integrate multiple power management functions into a single chip, enabling compact design and enhanced efficiency, while discrete components consist of separate individual elements like regulators, capacitors, and inductors. PMICs feature a centralized architecture with programmable control, allowing for dynamic voltage scaling and comprehensive power sequencing, whereas discrete designs rely on independent, fixed-function components that offer flexibility but require more board space and complex layout. The integration level in PMICs reduces electromagnetic interference and improves thermal performance compared to the distributed nature of discrete component arrangements.

Efficiency and Power Management

PMICs (Power Management Integrated Circuits) offer superior efficiency by integrating multiple power functions into a single chip, reducing energy loss and minimizing heat generation compared to discrete components. Your system benefits from precise voltage regulation and dynamic power scaling provided by PMICs, which optimize power distribution and enhance battery life. Discrete components, while customizable, often face higher power dissipation and increased complexity in power management design.

Space and Integration Considerations

Power Management Integrated Circuits (PMICs) significantly reduce PCB space by integrating multiple power functions into a single chip, minimizing the need for discrete components like inductors, capacitors, and regulators. This high level of integration not only optimizes board layout but also enhances overall system reliability and thermal management. Your designs benefit from simpler assembly processes and improved space utilization, which is critical in compact or portable electronic devices.

Cost Implications and Scalability

Power Management Integrated Circuits (PMICs) offer lower overall system costs compared to discrete components by consolidating multiple power functions into a single chip, reducing PCB space and assembly complexity. Discrete components may incur higher expenses due to individual part procurement, increased design complexity, and larger board area requirements, impacting both manufacturing and inventory management costs. Scalability favors PMICs as they provide modular power solutions adaptable to evolving product line needs, while discrete components often require redesign and additional validation for scaling.

Flexibility and Customization Options

PMICs offer integrated power management with limited flexibility, often designed for specific applications, while discrete components provide extensive customization options by allowing you to tailor voltage, current, and power sequencing to precise requirements. Discrete configurations enable easier modification and scalability for complex systems, supporting unique or evolving design needs. Choosing between PMICs and discrete solutions depends on your prioritization of streamlined integration versus detailed control and adaptability.

Reliability and Performance Comparison

PMICs (Power Management Integrated Circuits) offer enhanced reliability by integrating multiple power functions into a single chip, reducing component count and minimizing failure points compared to discrete components. Performance-wise, PMICs provide optimized power sequencing, improved efficiency, and better thermal management, ensuring stable voltage supply and reduced noise. Your system benefits from PMICs through compact design and consistent performance, while discrete components may allow more customization but often suffer from increased assembly complexity and potential reliability issues.

Typical Applications and Use Cases

Power Management ICs (PMICs) are ideal for compact consumer electronics like smartphones, tablets, and wearables where space efficiency and integrated functionality are critical. Discrete components are preferred in industrial and automotive applications requiring high-current handling and customization flexibility, such as motor control and power conversion systems. Your choice between PMICs and discrete components depends on factors like design complexity, thermal management, and specific voltage or current requirements.

Choosing the Right Solution for Your Project

Selecting between Power Management ICs (PMICs) and discrete components hinges on project complexity, space constraints, and power efficiency requirements. PMICs offer integrated solutions with multiple regulators, reducing PCB size and simplifying design, ideal for compact or battery-operated devices. Discrete components provide greater customization and scalability for specialized power needs but may increase board space and design time.

PMIC vs Discrete Components Infographic

electrown.com

electrown.com