High-K dielectrics offer superior capacitance and reduced leakage current compared to low-K dielectrics, making them essential in advanced semiconductor devices for improved performance and energy efficiency. Explore the rest of the article to understand how your choice between high-K and low-K dielectrics impacts device design and functionality.

Table of Comparison

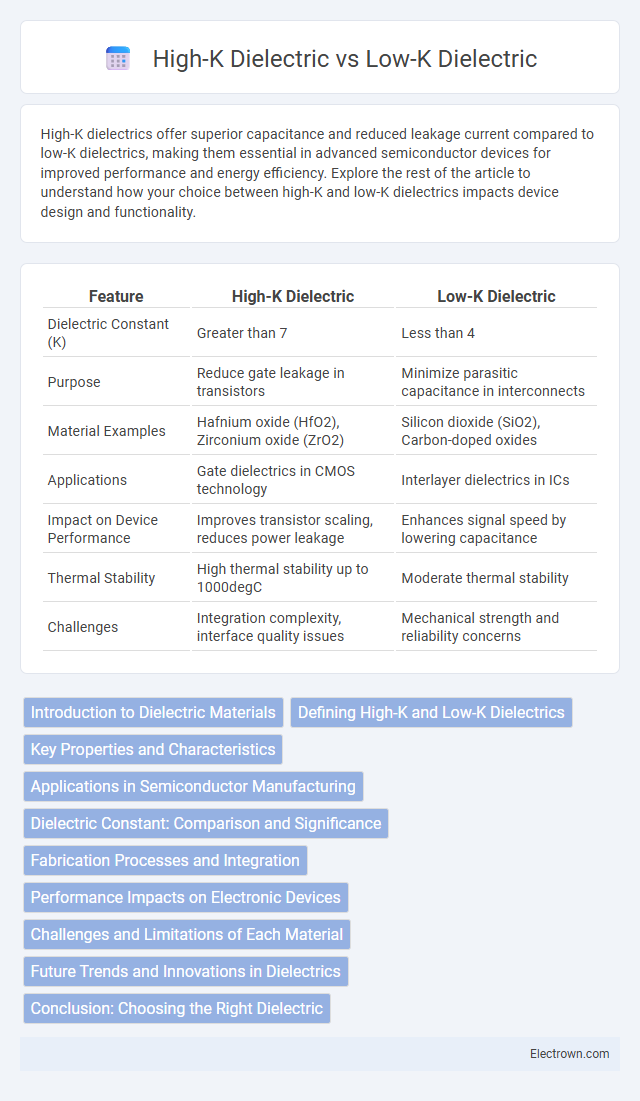

| Feature | High-K Dielectric | Low-K Dielectric |

|---|---|---|

| Dielectric Constant (K) | Greater than 7 | Less than 4 |

| Purpose | Reduce gate leakage in transistors | Minimize parasitic capacitance in interconnects |

| Material Examples | Hafnium oxide (HfO2), Zirconium oxide (ZrO2) | Silicon dioxide (SiO2), Carbon-doped oxides |

| Applications | Gate dielectrics in CMOS technology | Interlayer dielectrics in ICs |

| Impact on Device Performance | Improves transistor scaling, reduces power leakage | Enhances signal speed by lowering capacitance |

| Thermal Stability | High thermal stability up to 1000degC | Moderate thermal stability |

| Challenges | Integration complexity, interface quality issues | Mechanical strength and reliability concerns |

Introduction to Dielectric Materials

Dielectric materials, essential for insulating components in electronic devices, are classified into high-K and low-K types based on their dielectric constant values. High-K dielectrics exhibit a higher dielectric constant, improving capacitance and reducing leakage currents in transistors, while low-K dielectrics provide lower permittivity, minimizing parasitic capacitance for faster signal propagation. Understanding these properties helps you optimize semiconductor performance by choosing the appropriate dielectric material for specific device applications.

Defining High-K and Low-K Dielectrics

High-K dielectrics refer to materials with a high dielectric constant, typically greater than that of silicon dioxide, which enhances capacitance while reducing leakage current in semiconductor devices. Low-K dielectrics possess a lower dielectric constant, often below 3, and are primarily used to minimize parasitic capacitance and improve signal speed in integrated circuits. The selection between high-K and low-K dielectrics depends on balancing electrical performance, scaling requirements, and power efficiency in microelectronics.

Key Properties and Characteristics

High-K dielectrics exhibit a higher dielectric constant, often greater than 10, which significantly reduces gate leakage current in semiconductor devices and improves capacitance without increasing physical thickness. Low-K dielectrics have a dielectric constant typically below 3.5, offering lower parasitic capacitance and improved signal speed in interconnects, making them ideal for minimizing RC delay in integrated circuits. The choice between high-K and low-K materials depends on balancing gate efficiency and interconnect performance in advanced microelectronics.

Applications in Semiconductor Manufacturing

High-K dielectrics are essential in advanced semiconductor manufacturing for improving transistor gate capacitance, enabling further device scaling and reducing leakage currents in DRAM and CMOS technologies. Low-K dielectrics are primarily applied to minimize parasitic capacitance in interconnect layers, enhancing signal speed and reducing power consumption in integrated circuits. Both materials play critical roles in optimizing performance, with high-K dielectrics used for gate insulators and low-K dielectrics integrated into interlayer dielectrics to maintain signal integrity.

Dielectric Constant: Comparison and Significance

High-K dielectrics possess a dielectric constant significantly greater than traditional low-K materials, typically exceeding values of 10 compared to less than 4 for low-K dielectrics. This higher dielectric constant enables improved capacitive coupling and reduced gate leakage currents in semiconductor devices, enhancing transistor performance and power efficiency. The choice between high-K and low-K dielectrics critically influences device scaling, signal integrity, and overall integrated circuit reliability.

Fabrication Processes and Integration

High-K dielectrics utilize materials such as hafnium oxide deposited via atomic layer deposition (ALD) to achieve superior capacitance and reduce leakage currents in advanced semiconductor devices. Low-K dielectrics, typically silicon-based oxides or porous materials, are integrated using chemical vapor deposition (CVD) techniques to minimize parasitic capacitance in interconnects, enhancing signal speed. Integration challenges for High-K dielectrics include thermal stability and interface quality with metal gates, while Low-K dielectrics demand careful mechanical strength management to prevent cracking during back-end-of-line (BEOL) processing.

Performance Impacts on Electronic Devices

High-K dielectric materials enhance the performance of electronic devices by reducing gate leakage current and improving capacitance in transistors, enabling faster switching speeds and lower power consumption. Low-K dielectric materials are primarily used to minimize interconnect capacitance in integrated circuits, reducing signal delay and crosstalk for improved overall speed. Your choice between high-K and low-K dielectrics directly influences device efficiency, reliability, and scaling potential in semiconductor applications.

Challenges and Limitations of Each Material

High-K dielectrics present challenges such as increased leakage current due to trap states and compatibility issues with existing silicon processes, complicating integration in semiconductor devices. Low-K dielectrics suffer from mechanical fragility, reduced thermal stability, and difficulty maintaining low dielectric constants at nanoscale thicknesses, which limits their effectiveness in advanced integrated circuits. Your choice between these materials must consider trade-offs in electrical performance, manufacturability, and long-term device reliability.

Future Trends and Innovations in Dielectrics

Future trends in high-K and low-K dielectrics emphasize the development of materials with optimized permittivity and minimal leakage currents to enhance semiconductor device performance. Innovations include integrating novel high-K metal oxides and low-K porous organosilicates to reduce power consumption and improve scaling in advanced integrated circuits. Your choice of dielectric materials will significantly impact the efficiency and reliability of next-generation electronic components.

Conclusion: Choosing the Right Dielectric

High-K dielectrics offer superior capacitance and reduced leakage currents, making them ideal for advanced semiconductor devices requiring enhanced performance and power efficiency. Low-K dielectrics excel in minimizing parasitic capacitance, thus improving signal speed and reducing power consumption in interconnects for large-scale integrated circuits. Your choice depends on whether your application prioritizes gate insulation quality or interconnect speed, balancing performance demands with fabrication constraints.

High-K Dielectric vs Low-K Dielectric Infographic

electrown.com

electrown.com