Sintered silver offers superior thermal and electrical conductivity compared to traditional wire bonding, enhancing the performance and longevity of electronic components. Discover how choosing the right connection method can optimize your device's efficiency by reading the rest of the article.

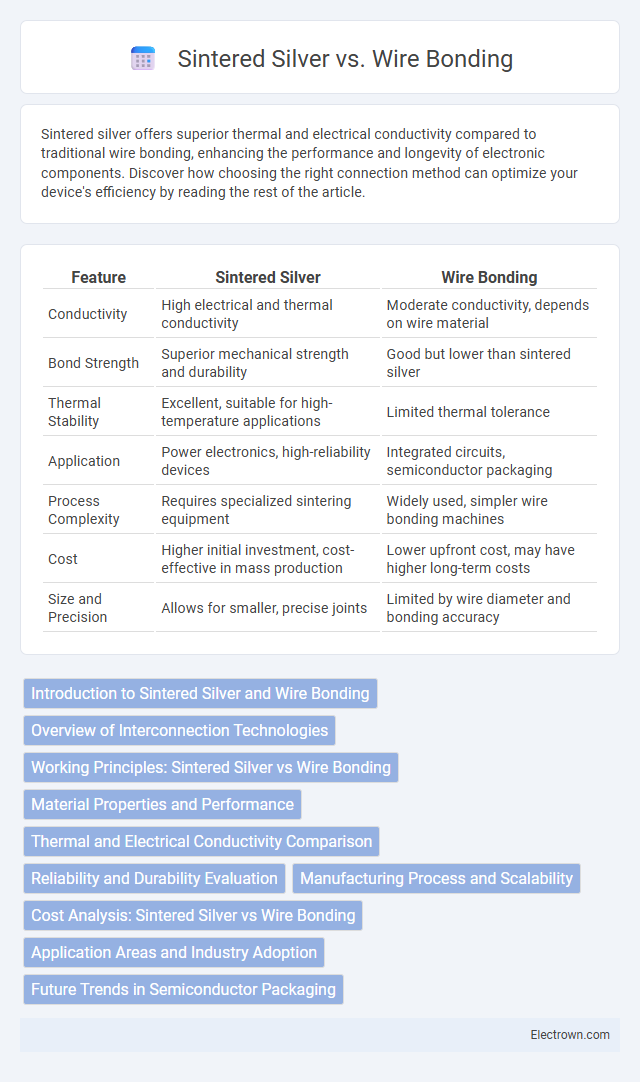

Table of Comparison

| Feature | Sintered Silver | Wire Bonding |

|---|---|---|

| Conductivity | High electrical and thermal conductivity | Moderate conductivity, depends on wire material |

| Bond Strength | Superior mechanical strength and durability | Good but lower than sintered silver |

| Thermal Stability | Excellent, suitable for high-temperature applications | Limited thermal tolerance |

| Application | Power electronics, high-reliability devices | Integrated circuits, semiconductor packaging |

| Process Complexity | Requires specialized sintering equipment | Widely used, simpler wire bonding machines |

| Cost | Higher initial investment, cost-effective in mass production | Lower upfront cost, may have higher long-term costs |

| Size and Precision | Allows for smaller, precise joints | Limited by wire diameter and bonding accuracy |

Introduction to Sintered Silver and Wire Bonding

Sintered silver is an advanced die-attach technology that uses high-temperature pressing to form a highly conductive, mechanically robust bond ideal for power electronics and high-reliability applications. Wire bonding involves creating electrical interconnections by ultrasonically or thermosonically bonding thin metal wires, commonly gold or copper, to semiconductor devices and substrates. Understanding the differences in electrical conductivity, mechanical strength, and thermal performance between sintered silver and wire bonding is essential for optimizing your electronic device packaging.

Overview of Interconnection Technologies

Sintered silver and wire bonding are critical interconnection technologies in advanced electronics packaging, each offering distinct advantages in thermal conductivity and mechanical strength. Sintered silver provides superior electrical performance and high-temperature stability due to its dense, porous microstructure, making it ideal for power electronics and high-reliability applications. Wire bonding remains a cost-effective, versatile solution widely used for high-volume semiconductor packaging, ensuring reliable electrical connections through fine metal wires such as gold, aluminum, or copper.

Working Principles: Sintered Silver vs Wire Bonding

Sintered silver uses high-temperature compression to fuse silver particles into a solid, conductive joint, providing superior thermal and electrical conductivity with enhanced mechanical strength. Wire bonding relies on ultrasonic or thermocompression techniques to create fine metal wire connections between semiconductor devices and substrates, suitable for complex circuit integration. Both methods optimize electrical performance but differ significantly in application scale and thermal management capabilities.

Material Properties and Performance

Sintered silver exhibits superior thermal conductivity and mechanical strength compared to traditional wire bonding materials, enabling enhanced heat dissipation in high-power electronic applications. The porous structure formed during the sintering process provides improved electrical performance with lower resistance and higher current-carrying capacity. Wire bonding, typically using gold or aluminum wires, offers flexibility and cost-effectiveness but generally falls short in thermal management and long-term reliability under harsh operating conditions.

Thermal and Electrical Conductivity Comparison

Sintered silver offers superior thermal conductivity, approximately 330 W/m*K, compared to traditional wire bonding materials like gold, which typically have thermal conductivity around 318 W/m*K. Electrical conductivity in sintered silver is also higher, with its bulk conductivity reaching up to 6.3 x 10^7 S/m, outperforming gold wire bonds that average about 4.1 x 10^7 S/m. These characteristics make sintered silver preferable for applications requiring efficient heat dissipation and electrical performance in power electronics.

Reliability and Durability Evaluation

Sintered silver exhibits superior reliability and durability compared to wire bonding, with enhanced resistance to thermal cycling and mechanical stress, leading to prolonged lifespan in high-power electronics. Its porous microstructure allows better heat dissipation, reducing failures associated with thermal fatigue that commonly affect wire bonds. Evaluation tests confirm sintered silver joints maintain electrical integrity under harsh conditions where wire bonding often experiences bond lift-off or cracking.

Manufacturing Process and Scalability

Sintered silver involves a high-temperature process where silver particles fuse into a solid mass, offering superior thermal and electrical conductivity ideal for high-power applications. Wire bonding uses fine metal wires attached via ultrasonic or thermosonic welding, enabling precise connections but with potential scalability limits due to slower production speeds. Your choice depends on manufacturing volume and performance needs, with sintered silver providing scalability for large-scale production and wire bonding excelling in delicate, low-volume assemblies.

Cost Analysis: Sintered Silver vs Wire Bonding

Sintered silver offers superior thermal conductivity and mechanical strength compared to traditional wire bonding, but its initial material and processing costs are higher. Wire bonding remains a cost-effective choice for large-scale production due to lower equipment expenses and established manufacturing infrastructure. Evaluating total cost of ownership, including yield rates and long-term reliability, is crucial when comparing sintered silver and wire bonding in semiconductor packaging applications.

Application Areas and Industry Adoption

Sintered silver technology is widely adopted in high-power electronics and automotive sectors for its superior thermal and electrical conductivity, enabling efficient heat dissipation in electric vehicle batteries and power modules. Wire bonding remains prevalent in semiconductor packaging, telecommunications, and consumer electronics due to its cost-effectiveness and precision in connecting integrated circuits. Your choice between sintered silver and wire bonding depends on the application's performance requirements and industry standards.

Future Trends in Semiconductor Packaging

Sintered silver offers superior thermal conductivity and mechanical strength compared to traditional wire bonding, positioning it as a key material in advanced semiconductor packaging. Future trends emphasize enhancing package reliability and miniaturization, where sintered silver's high-performance bonding will support higher power densities and faster signal transmission. Your choice of interconnect technology will increasingly favor sintered silver for next-generation devices needing robust thermal management and electrical performance.

Sintered Silver vs Wire Bonding Infographic

electrown.com

electrown.com