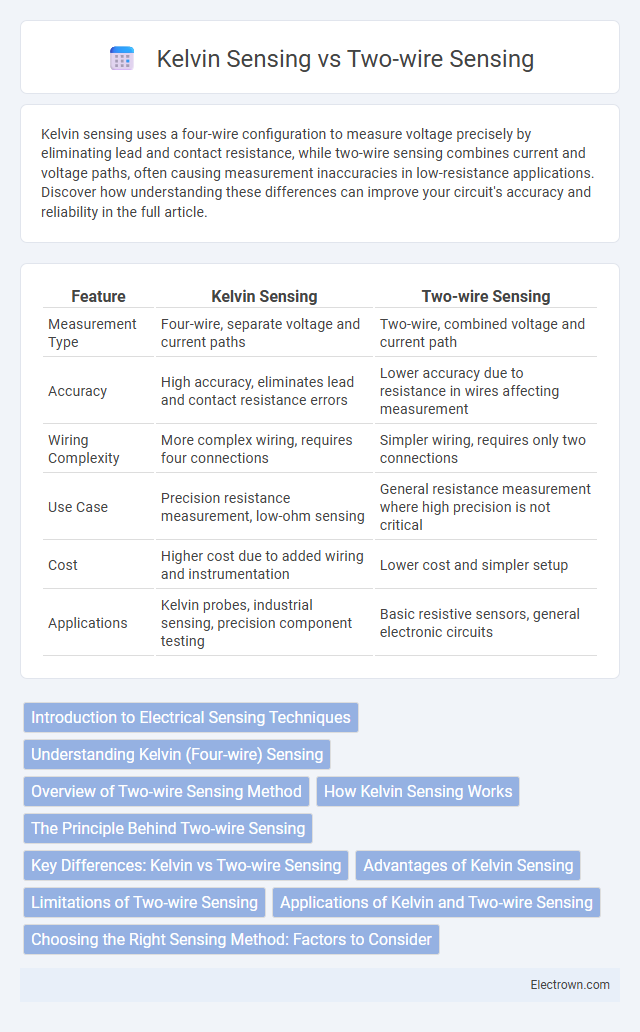

Kelvin sensing uses a four-wire configuration to measure voltage precisely by eliminating lead and contact resistance, while two-wire sensing combines current and voltage paths, often causing measurement inaccuracies in low-resistance applications. Discover how understanding these differences can improve your circuit's accuracy and reliability in the full article.

Table of Comparison

| Feature | Kelvin Sensing | Two-wire Sensing |

|---|---|---|

| Measurement Type | Four-wire, separate voltage and current paths | Two-wire, combined voltage and current path |

| Accuracy | High accuracy, eliminates lead and contact resistance errors | Lower accuracy due to resistance in wires affecting measurement |

| Wiring Complexity | More complex wiring, requires four connections | Simpler wiring, requires only two connections |

| Use Case | Precision resistance measurement, low-ohm sensing | General resistance measurement where high precision is not critical |

| Cost | Higher cost due to added wiring and instrumentation | Lower cost and simpler setup |

| Applications | Kelvin probes, industrial sensing, precision component testing | Basic resistive sensors, general electronic circuits |

Introduction to Electrical Sensing Techniques

Electrical sensing techniques like Kelvin Sensing and Two-wire Sensing are essential for accurate resistance measurements in electronic circuits. Kelvin Sensing uses a four-wire configuration to eliminate the effects of lead and contact resistance, providing highly precise readings for low-resistance components. Your choice between these methods depends on the required measurement accuracy and the nature of the electronic application.

Understanding Kelvin (Four-wire) Sensing

Kelvin sensing, also known as four-wire sensing, enhances measurement accuracy by separating the current-carrying and voltage-sensing leads, eliminating the effects of lead and contact resistance. This technique uses two wires to supply current and two additional wires to measure voltage directly at the load, ensuring precise resistance and voltage readings. Your measurements benefit from reduced errors and increased reliability, especially in low-resistance or highly sensitive applications compared to traditional two-wire sensing methods.

Overview of Two-wire Sensing Method

Two-wire sensing measures voltage directly at the device terminals using only two wires, making it simpler and cost-effective for basic applications. This method can introduce measurement errors due to voltage drops along the lead wires, especially in longer cable runs. You should consider factors like wire resistance and load current when choosing two-wire sensing to ensure accurate results.

How Kelvin Sensing Works

Kelvin Sensing works by using separate pairs of wires for current supply and voltage measurement, eliminating the effects of lead and contact resistance in precise electrical measurements. This method ensures that the voltage is measured directly across the component, while the current flows through a different path, providing highly accurate resistance readings even in low-resistance materials. Your measurements become more reliable with Kelvin Sensing, especially in applications requiring high precision like semiconductor testing and material characterization.

The Principle Behind Two-wire Sensing

The principle behind two-wire sensing involves using the same pair of wires to both power the sensor and transmit the measurement signal, which simplifies wiring but can introduce errors due to voltage drops along the line. Kelvin sensing, also known as four-wire sensing, uses separate pairs for current supply and voltage measurement, eliminating the influence of lead resistance and enhancing accuracy, especially in low-resistance measurements. Your choice between these methods depends on the precision required and the complexity you can manage in your sensor wiring setup.

Key Differences: Kelvin vs Two-wire Sensing

Kelvin sensing uses four wires to measure resistance, eliminating the effect of lead and contact resistance for highly accurate readings in low-resistance measurements, whereas two-wire sensing relies on just two wires and includes lead resistance in the measurement. Kelvin sensing is essential in precision applications like micro-ohm measurements and strain gauges, while two-wire sensing suffices for general purpose resistance checks with less accuracy. The fundamental difference lies in Kelvin sensing's separate voltage and current paths, enabling precise voltage drop measurement directly across the test object, unlike two-wire sensing.

Advantages of Kelvin Sensing

Kelvin sensing offers precise voltage measurements by eliminating the effects of lead and contact resistance, making it ideal for low-resistance measurements in sensitive applications. It uses separate pairs of current-carrying and voltage-sensing wires, ensuring accurate readings and improved measurement reliability compared to two-wire sensing. This technique enhances accuracy in high-precision instrumentation, calibration, and power electronics by reducing measurement errors caused by resistive losses in leads.

Limitations of Two-wire Sensing

Two-wire sensing is limited by voltage drops caused by lead resistance, which reduces measurement accuracy in low-resistance sensors. The inability to separate the sensing and excitation paths means that temperature variations and wire length significantly affect the measured signal. Kelvin sensing overcomes these issues by using separate pairs of wires for current supply and voltage measurement, ensuring precise and stable readings.

Applications of Kelvin and Two-wire Sensing

Kelvin sensing is widely used in precision measurements and low-resistance testing applications where accurate current and voltage separation is critical, such as in battery testing, semiconductor devices, and strain gauge measurements. Two-wire sensing is commonly applied in general resistance measurements and circuits where simplicity and cost-effectiveness are priorities, including basic resistance checks and low-accuracy industrial controls. Your choice between Kelvin and two-wire sensing depends on the required measurement accuracy and application complexity.

Choosing the Right Sensing Method: Factors to Consider

Kelvin sensing provides precise voltage measurements by using separate pairs of wires for current supply and voltage sensing, minimizing measurement errors caused by lead resistance, making it ideal for low-resistance or high-accuracy applications. Two-wire sensing, while simpler and cost-effective, combines current supply and voltage measurement in the same leads, which can introduce inaccuracies in high-current or long-distance setups due to voltage drops. Your choice depends on factors such as required measurement accuracy, wire length, current magnitude, and budget constraints to ensure optimal performance and reliability.

Kelvin Sensing vs Two-wire Sensing Infographic

electrown.com

electrown.com