Nanowire transistors offer enhanced electron mobility and scalability compared to nanotube transistors, which are known for their exceptional electrical conductivity and mechanical strength. Discover the key differences and applications that could impact your next semiconductor innovation by reading the full article.

Table of Comparison

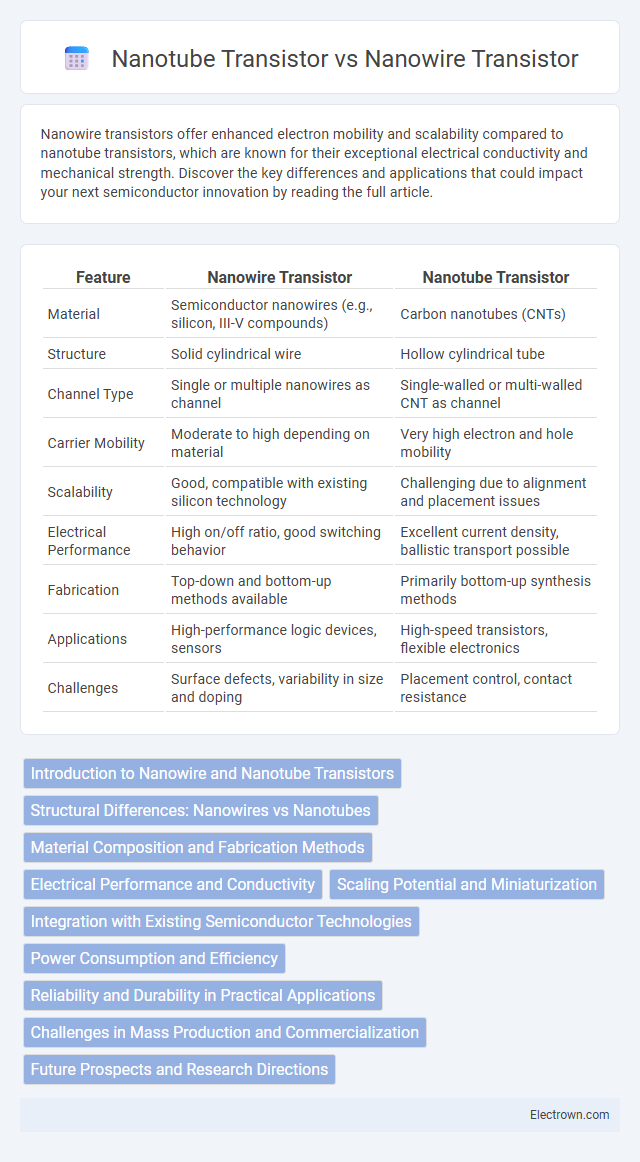

| Feature | Nanowire Transistor | Nanotube Transistor |

|---|---|---|

| Material | Semiconductor nanowires (e.g., silicon, III-V compounds) | Carbon nanotubes (CNTs) |

| Structure | Solid cylindrical wire | Hollow cylindrical tube |

| Channel Type | Single or multiple nanowires as channel | Single-walled or multi-walled CNT as channel |

| Carrier Mobility | Moderate to high depending on material | Very high electron and hole mobility |

| Scalability | Good, compatible with existing silicon technology | Challenging due to alignment and placement issues |

| Electrical Performance | High on/off ratio, good switching behavior | Excellent current density, ballistic transport possible |

| Fabrication | Top-down and bottom-up methods available | Primarily bottom-up synthesis methods |

| Applications | High-performance logic devices, sensors | High-speed transistors, flexible electronics |

| Challenges | Surface defects, variability in size and doping | Placement control, contact resistance |

Introduction to Nanowire and Nanotube Transistors

Nanowire transistors utilize semiconductor nanowires as the channel material, offering excellent electrostatic control and scalability for advanced integrated circuits. Nanotube transistors, primarily based on carbon nanotubes, provide exceptional electrical conductivity and high carrier mobility, enabling high-performance nanoscale devices. Both technologies represent critical advancements in nanoscale transistor engineering, with distinct structural and material properties influencing their integration in future electronics.

Structural Differences: Nanowires vs Nanotubes

Nanowire transistors consist of solid, cylindrical semiconductor structures with uniform cross-sections, while nanotube transistors feature hollow, cylindrical carbon-based tubes with distinctive chirality affecting their electronic properties. The solid structure of nanowires allows easier doping and integration in traditional semiconductor processes, whereas nanotubes offer exceptional electrical conductivity and mechanical strength due to their atomic-scale hollow geometry. Your choice between nanowire and nanotube transistors depends on the desired electronic performance and fabrication compatibility in advanced nanoscale devices.

Material Composition and Fabrication Methods

Nanowire transistors are typically constructed from semiconductor materials such as silicon or III-V compounds, using top-down lithography or bottom-up chemical vapor deposition techniques. Nanotube transistors primarily rely on carbon nanotubes, fabricated through methods like chemical vapor deposition, which enable precise control over chirality and conductivity. Understanding the distinct material compositions and fabrication methods helps optimize Your device performance for targeted electronic applications.

Electrical Performance and Conductivity

Nanowire transistors exhibit superior electrical performance due to their well-controlled diameter and crystalline structure, enabling consistent electron mobility and reduced scattering effects. Carbon nanotube transistors offer exceptional conductivity attributed to their ballistic transport properties and high current-carrying capacity, resulting in near-ideal channel conductance. Comparing both, nanowire transistors deliver stable performance in traditional semiconductor materials, while nanotube transistors excel in high-speed, low-power applications because of their intrinsic nanoscale conductivity advantages.

Scaling Potential and Miniaturization

Nanowire transistors exhibit superior scaling potential due to their well-defined, uniform geometry and excellent electrostatic control, enabling aggressive miniaturization beyond the limits of traditional planar devices. Nanotube transistors, while offering exceptional electrical properties like high carrier mobility, face challenges in consistent fabrication and alignment at extremely small scales, limiting their miniaturization prospects. The inherent structural advantages of nanowires facilitate more reliable scaling to sub-5nm regimes essential for next-generation semiconductor technologies.

Integration with Existing Semiconductor Technologies

Nanowire transistors offer superior compatibility with existing semiconductor fabrication processes due to their similar crystal structures and established doping techniques, enabling easier integration into current silicon-based technology. Nanotube transistors, while possessing excellent electrical properties, face challenges in uniform placement and reproducibility which complicate their direct incorporation into standard semiconductor manufacturing. Your choice between these technologies depends on the balance between integration feasibility and performance requirements for next-generation electronic devices.

Power Consumption and Efficiency

Nanowire transistors exhibit lower power consumption due to their superior gate control and reduced short-channel effects compared to nanotube transistors, which can suffer from variability in electrical properties. Nanotube transistors, however, offer higher carrier mobility, potentially improving switching speed but often at the cost of increased leakage currents. Your choice between nanowire and nanotube transistors should balance these factors to optimize overall efficiency for specific low-power applications.

Reliability and Durability in Practical Applications

Nanowire transistors offer enhanced reliability in practical applications due to their well-defined crystalline structure, which reduces defect-induced performance degradation over time. Carbon nanotube transistors demonstrate superior durability under mechanical stress and high current densities, maintaining consistent performance in flexible and wearable electronics. To maximize your device's lifespan, consider nanowire transistors for stable, long-term operation, while nanotube transistors excel in environments requiring flexibility and resilience.

Challenges in Mass Production and Commercialization

Nanowire transistors face challenges in mass production due to precise control required over nanowire alignment and uniformity, while nanotube transistors struggle with consistent synthesis of high-purity, defect-free nanotubes at scale. Both technologies require advanced fabrication techniques to ensure device reliability and integration with existing semiconductor processes. Your choice between these transistors should consider current manufacturing limitations and scalability for commercial applications.

Future Prospects and Research Directions

Nanowire transistors offer precise control over electrical properties due to their uniform crystalline structure, making them promising candidates for scaling beyond traditional silicon devices. Nanotube transistors, particularly those based on carbon nanotubes, exhibit exceptional electron mobility and flexibility, positioning them as strong contenders for future flexible electronics and high-performance computing. Your choice between these technologies will depend on ongoing research advancements aimed at overcoming fabrication challenges and integrating them into existing semiconductor processes.

Nanowire Transistor vs Nanotube Transistor Infographic

electrown.com

electrown.com