Tunneling Magnetoresistance (TMR) relies on electron tunneling through an insulating barrier between ferromagnetic layers, offering higher sensitivity and flexibility in magnetic sensor applications compared to Giant Magnetoresistance (GMR), which depends on electron scattering in multilayer metallic structures. Explore the rest of the article to understand how these effects impact your choice of magnetic devices and technologies.

Table of Comparison

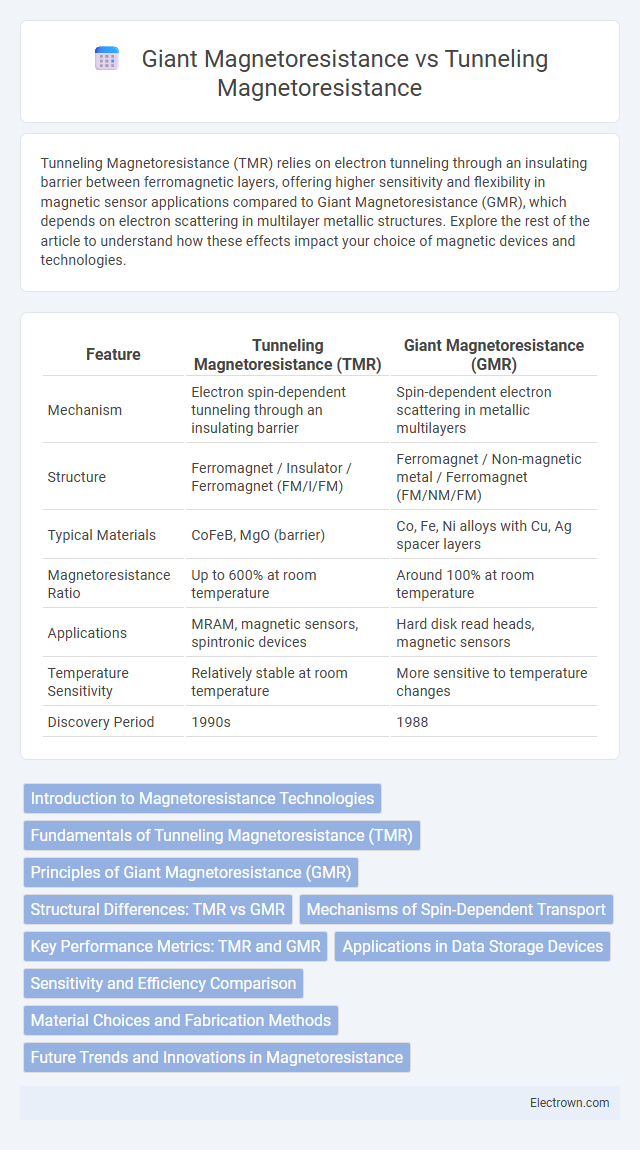

| Feature | Tunneling Magnetoresistance (TMR) | Giant Magnetoresistance (GMR) |

|---|---|---|

| Mechanism | Electron spin-dependent tunneling through an insulating barrier | Spin-dependent electron scattering in metallic multilayers |

| Structure | Ferromagnet / Insulator / Ferromagnet (FM/I/FM) | Ferromagnet / Non-magnetic metal / Ferromagnet (FM/NM/FM) |

| Typical Materials | CoFeB, MgO (barrier) | Co, Fe, Ni alloys with Cu, Ag spacer layers |

| Magnetoresistance Ratio | Up to 600% at room temperature | Around 100% at room temperature |

| Applications | MRAM, magnetic sensors, spintronic devices | Hard disk read heads, magnetic sensors |

| Temperature Sensitivity | Relatively stable at room temperature | More sensitive to temperature changes |

| Discovery Period | 1990s | 1988 |

Introduction to Magnetoresistance Technologies

Tunneling Magnetoresistance (TMR) and Giant Magnetoresistance (GMR) represent two critical advancements in magnetoresistance technologies, essential for developing high-performance magnetic sensors and memory devices. TMR operates through quantum tunneling of electrons across an insulating barrier, typically yielding higher magnetoresistance ratios than GMR, which relies on spin-dependent electron scattering in multilayer metallic structures. Understanding these distinctions helps optimize Your selection of magnetoresistive components for applications demanding high sensitivity and data storage efficiency.

Fundamentals of Tunneling Magnetoresistance (TMR)

Tunneling Magnetoresistance (TMR) occurs when electrons tunnel through an insulating barrier between two ferromagnetic layers, with the resistance depending on the relative alignment of their magnetizations. The spin-dependent tunneling current varies as the magnetizations switch between parallel and antiparallel states, producing high sensitivity in magnetic sensors and memory devices. Your understanding of TMR's fundamental principle lies in the quantum mechanical tunneling effect combined with spin polarization of conduction electrons.

Principles of Giant Magnetoresistance (GMR)

Giant Magnetoresistance (GMR) operates on the principle of spin-dependent electron scattering in layered magnetic and non-magnetic materials, causing significant changes in electrical resistance when the magnetic layers' alignment switches from parallel to antiparallel. This effect arises due to electron spin polarization, where conduction electrons experience different scattering rates based on their spin orientation relative to the magnetization direction. Understanding GMR's spin valve structures can enhance your ability to design advanced magnetic sensors and memory devices.

Structural Differences: TMR vs GMR

Tunneling Magnetoresistance (TMR) and Giant Magnetoresistance (GMR) exhibit distinct structural differences that influence their magnetoresistive behavior. TMR devices consist of two ferromagnetic layers separated by a thin insulating tunnel barrier, typically magnesium oxide (MgO), allowing electron spin-dependent tunneling. In contrast, GMR structures employ alternating ferromagnetic and non-magnetic metallic layers, such as cobalt and copper, where electron scattering at interfaces causes resistance changes.

Mechanisms of Spin-Dependent Transport

Tunneling Magnetoresistance (TMR) relies on spin-dependent electron tunneling through an insulating barrier between two ferromagnetic layers, where the resistance changes based on the relative alignment of their magnetizations. Giant Magnetoresistance (GMR) involves spin-dependent scattering of conduction electrons in alternating ferromagnetic and non-magnetic metallic layers, resulting in significant resistance variation with layer magnetization orientation. Both phenomena exploit spin polarization but differ fundamentally in electron transport mechanisms: quantum tunneling in TMR versus diffusive conduction and spin scattering in GMR.

Key Performance Metrics: TMR and GMR

Tunneling Magnetoresistance (TMR) typically exhibits higher magnetoresistance ratios, often exceeding 200%, compared to Giant Magnetoresistance (GMR) which usually ranges between 10-80%. TMR devices benefit from a tunnel barrier that enhances spin-dependent electron tunneling, resulting in greater signal modulation and sensitivity for magnetic sensing or memory applications. Your choice between TMR and GMR should consider factors such as operating voltage, temperature stability, and integration requirements, with TMR offering superior performance in high-density magnetic random access memory (MRAM) technologies.

Applications in Data Storage Devices

Tunneling Magnetoresistance (TMR) and Giant Magnetoresistance (GMR) play crucial roles in enhancing data storage devices by improving read-head sensitivity and data density. TMR, utilizing magnetic tunnel junctions, offers higher magnetoresistance ratios and thermal stability, making it the preferred technology in modern hard disk drives and MRAM (Magnetoresistive Random-Access Memory). Your data storage performance benefits from TMR's superior signal-to-noise ratio, while GMR remains valuable in earlier-generation devices due to its simpler multilayer thin-film structures.

Sensitivity and Efficiency Comparison

Tunneling Magnetoresistance (TMR) exhibits higher sensitivity than Giant Magnetoresistance (GMR) due to the quantum tunneling effect across an insulating barrier, enabling larger resistance changes under magnetic field variations. TMR devices also offer superior efficiency in spintronic applications by producing stronger signal modulation at lower power consumption. Understanding these differences helps optimize Your design choices for magnetic sensors and memory technologies.

Material Choices and Fabrication Methods

Tunneling Magnetoresistance (TMR) primarily uses magnetic tunnel junctions composed of ferromagnetic layers separated by an ultra-thin insulating barrier, often MgO, which enables spin-dependent tunneling, whereas Giant Magnetoresistance (GMR) relies on alternating ferromagnetic and non-magnetic conductive metal layers such as Co/Cu or Fe/Cr. Fabrication of TMR devices requires precise atomic-scale control through methods like sputtering and molecular beam epitaxy to create defect-free tunnel barriers, while GMR structures are typically fabricated using sputtering or electrodeposition techniques to assemble multilayer thin films. The choice of materials and fabrication processes directly impacts the magnetoresistive ratio and thermal stability, with MgO-based TMR junctions achieving higher magnetoresistance compared to metallic GMR stacks.

Future Trends and Innovations in Magnetoresistance

Emerging advancements in tunneling magnetoresistance (TMR) focus on enhancing voltage-controlled magnetic anisotropy and spin-orbit torque for low-power memory and logic applications, outperforming giant magnetoresistance (GMR) in signal stability and scalability. Innovations in material engineering, such as the integration of two-dimensional materials and topological insulators, promise to push TMR device sensitivity and operational speed beyond the current GMR limits. The convergence of spintronic technologies and quantum computing architectures highlights the potential of TMR to revolutionize data storage and processing efficiency in next-generation magnetoresistive devices.

Tunneling Magnetoresistance vs Giant Magnetoresistance Infographic

electrown.com

electrown.com