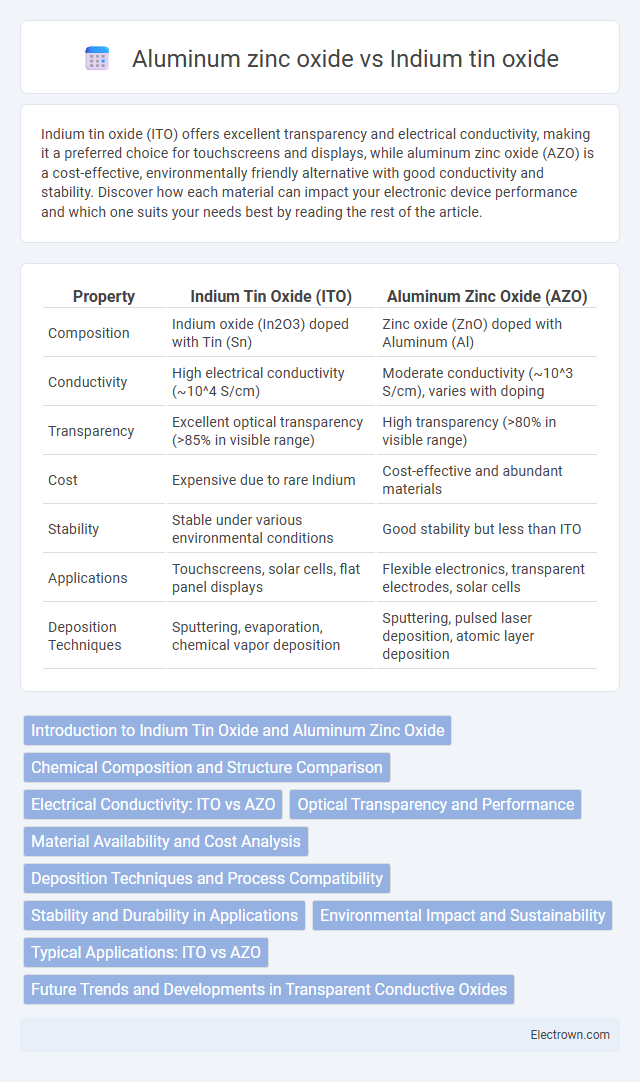

Indium tin oxide (ITO) offers excellent transparency and electrical conductivity, making it a preferred choice for touchscreens and displays, while aluminum zinc oxide (AZO) is a cost-effective, environmentally friendly alternative with good conductivity and stability. Discover how each material can impact your electronic device performance and which one suits your needs best by reading the rest of the article.

Table of Comparison

| Property | Indium Tin Oxide (ITO) | Aluminum Zinc Oxide (AZO) |

|---|---|---|

| Composition | Indium oxide (In2O3) doped with Tin (Sn) | Zinc oxide (ZnO) doped with Aluminum (Al) |

| Conductivity | High electrical conductivity (~10^4 S/cm) | Moderate conductivity (~10^3 S/cm), varies with doping |

| Transparency | Excellent optical transparency (>85% in visible range) | High transparency (>80% in visible range) |

| Cost | Expensive due to rare Indium | Cost-effective and abundant materials |

| Stability | Stable under various environmental conditions | Good stability but less than ITO |

| Applications | Touchscreens, solar cells, flat panel displays | Flexible electronics, transparent electrodes, solar cells |

| Deposition Techniques | Sputtering, evaporation, chemical vapor deposition | Sputtering, pulsed laser deposition, atomic layer deposition |

Introduction to Indium Tin Oxide and Aluminum Zinc Oxide

Indium tin oxide (ITO) and aluminum zinc oxide (AZO) are transparent conductive oxides widely used in optoelectronic devices such as touchscreens, solar cells, and displays. ITO is prized for its excellent electrical conductivity and optical transparency, though its reliance on rare indium makes it expensive. AZO offers a cost-effective, abundant alternative with good conductivity and transparency, making it suitable for your devices seeking sustainable and efficient transparent electrodes.

Chemical Composition and Structure Comparison

Indium tin oxide (ITO) consists of indium oxide (In2O3) doped with tin oxide (SnO2), forming a crystalline structure that offers high electrical conductivity and optical transparency. Aluminum zinc oxide (AZO) is composed of zinc oxide (ZnO) doped with aluminum (Al), exhibiting a wurtzite crystal structure that provides comparable transparency with enhanced conductivity stability under specific conditions. Your choice between ITO and AZO depends on the desired balance of conductivity, transparency, material availability, and cost-effectiveness for electronic or optoelectronic applications.

Electrical Conductivity: ITO vs AZO

Indium tin oxide (ITO) exhibits higher electrical conductivity compared to aluminum zinc oxide (AZO) due to its superior carrier concentration and mobility, making ITO the preferred choice for applications requiring low resistivity transparent conductors. AZO offers moderate conductivity with the advantage of lower cost and better environmental stability, though its resistivity is typically one order of magnitude higher than that of ITO. The conductivity differences arise from the intrinsic material properties and doping efficiencies, impacting their performance in optoelectronic devices such as touch screens and photovoltaic cells.

Optical Transparency and Performance

Indium tin oxide (ITO) offers superior optical transparency in the visible spectrum, typically exceeding 85%, making it ideal for high-performance touchscreens and displays. Aluminum zinc oxide (AZO) presents a comparable transparency level but at a lower cost and with better thermal stability, enhancing performance in flexible electronics. Your choice depends on balancing transparency needs with budget and device durability requirements.

Material Availability and Cost Analysis

Indium tin oxide (ITO) is widely used in transparent conductive applications but faces supply limitations due to the scarcity of indium, resulting in higher material costs. Aluminum zinc oxide (AZO) offers a more abundant and cost-effective alternative, utilizing readily available aluminum and zinc materials that reduce overall production expenses. Your choice between ITO and AZO will depend on balancing performance requirements with budget constraints influenced by material availability and cost.

Deposition Techniques and Process Compatibility

Indium tin oxide (ITO) is predominantly deposited using sputtering techniques such as magnetron sputtering, offering excellent film uniformity and conductivity suitable for photovoltaic and display applications. Aluminum zinc oxide (AZO) can be deposited via sputtering or atomic layer deposition (ALD), providing greater process flexibility and lower cost alternatives while maintaining good electrical properties. AZO's compatibility with lower temperature processes enables integration with flexible substrates and temperature-sensitive electronics, contrasting with the higher temperature constraints typical for ITO deposition.

Stability and Durability in Applications

Indium tin oxide (ITO) offers superior stability and durability in applications requiring transparent conductive coatings, with excellent resistance to environmental factors such as moisture and heat. Aluminum zinc oxide (AZO) presents good mechanical stability but tends to degrade faster under prolonged exposure to humidity and ultraviolet light. When choosing a material for your device, ITO generally ensures longer-lasting performance in harsh conditions compared to AZO.

Environmental Impact and Sustainability

Indium tin oxide (ITO) involves the use of indium, a rare and non-renewable resource, raising concerns about its environmental sustainability due to limited availability and energy-intensive extraction processes. Aluminum zinc oxide (AZO) offers a more eco-friendly alternative, utilizing abundant elements and enabling lower energy consumption during production, which reduces its overall environmental footprint. Choosing AZO for transparent conducting films can enhance the sustainability of your device manufacturing by minimizing resource depletion and supporting greener material sourcing.

Typical Applications: ITO vs AZO

Indium tin oxide (ITO) is predominantly used in touchscreen displays, flat-panel displays, and solar cells due to its superior electrical conductivity and optical transparency. Aluminum zinc oxide (AZO) serves as a cost-effective alternative in applications such as thin-film transistors, organic light-emitting diodes (OLEDs), and transparent electrodes for photovoltaics, offering good transparency and stability. ITO remains the industry standard for high-performance optoelectronic devices, while AZO is favored for large-area and flexible electronics because of its abundant material availability and lower toxicity.

Future Trends and Developments in Transparent Conductive Oxides

Indium tin oxide (ITO) remains the industry standard for transparent conductive oxides due to its excellent conductivity and optical transparency, but future trends are shifting towards aluminum zinc oxide (AZO) because of its lower cost, abundance, and environmental friendliness. Developments in nanostructuring and doping techniques are enhancing AZO's performance, making it a viable alternative for flexible electronics and next-generation displays. Your choice between ITO and AZO will depend on balancing performance requirements with sustainability and cost considerations in emerging transparent conductive applications.

Indium tin oxide vs Aluminum zinc oxide Infographic

electrown.com

electrown.com