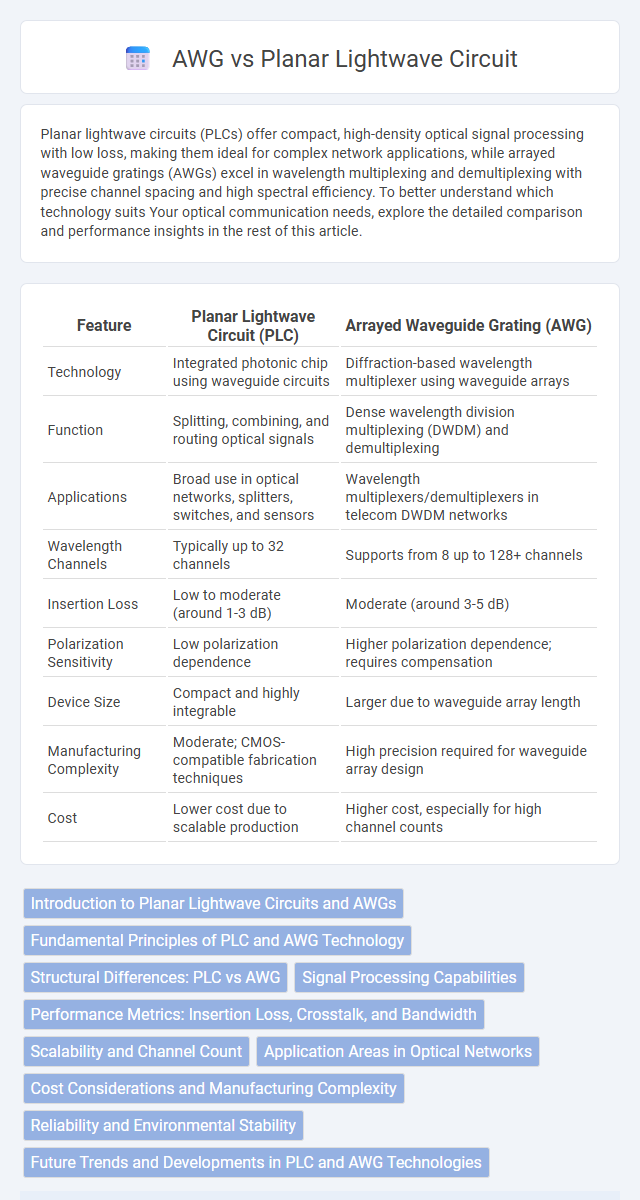

Planar lightwave circuits (PLCs) offer compact, high-density optical signal processing with low loss, making them ideal for complex network applications, while arrayed waveguide gratings (AWGs) excel in wavelength multiplexing and demultiplexing with precise channel spacing and high spectral efficiency. To better understand which technology suits Your optical communication needs, explore the detailed comparison and performance insights in the rest of this article.

Table of Comparison

| Feature | Planar Lightwave Circuit (PLC) | Arrayed Waveguide Grating (AWG) |

|---|---|---|

| Technology | Integrated photonic chip using waveguide circuits | Diffraction-based wavelength multiplexer using waveguide arrays |

| Function | Splitting, combining, and routing optical signals | Dense wavelength division multiplexing (DWDM) and demultiplexing |

| Applications | Broad use in optical networks, splitters, switches, and sensors | Wavelength multiplexers/demultiplexers in telecom DWDM networks |

| Wavelength Channels | Typically up to 32 channels | Supports from 8 up to 128+ channels |

| Insertion Loss | Low to moderate (around 1-3 dB) | Moderate (around 3-5 dB) |

| Polarization Sensitivity | Low polarization dependence | Higher polarization dependence; requires compensation |

| Device Size | Compact and highly integrable | Larger due to waveguide array length |

| Manufacturing Complexity | Moderate; CMOS-compatible fabrication techniques | High precision required for waveguide array design |

| Cost | Lower cost due to scalable production | Higher cost, especially for high channel counts |

Introduction to Planar Lightwave Circuits and AWGs

Planar Lightwave Circuits (PLCs) and Arrayed Waveguide Gratings (AWGs) are essential components in optical communication networks, enabling efficient multiplexing and demultiplexing of wavelength channels. PLCs utilize silica-based waveguides fabricated on a flat substrate to guide light with low loss, while AWGs, a specialized type of PLC, employ an array of waveguides with precise length differences to disperse optical signals by wavelength. Understanding the role of PLCs and AWGs can enhance your network design by optimizing wavelength routing and signal integrity in dense wavelength division multiplexing (DWDM) systems.

Fundamental Principles of PLC and AWG Technology

Planar lightwave circuits (PLCs) utilize waveguide technology on silica-based substrates to split or combine optical signals with high precision and stability through photolithographic fabrication. Arrayed waveguide gratings (AWGs) function by employing a series of waveguides with varying path lengths to create constructive interference patterns, enabling the multiplexing and demultiplexing of multiple wavelengths simultaneously. Both technologies form the backbone of wavelength division multiplexing (WDM) systems, with PLCs providing compact and low-loss components while AWGs offer high spectral resolution and channel isolation.

Structural Differences: PLC vs AWG

Planar Lightwave Circuits (PLC) and Arrayed Waveguide Gratings (AWG) differ structurally in their waveguide configurations and fabrication techniques. PLCs use planar waveguides etched on a flat substrate, enabling compact, integrated photonic circuits with precise optical path control, while AWGs employ a phased array of waveguides with varying lengths to produce specific wavelength delays for multiplexing or demultiplexing signals. The key structural distinction lies in PLC's uniform waveguide patterns suited for diverse integrated functions compared to AWG's curved, non-uniform waveguide array optimized for wavelength routing in dense wavelength division multiplexing (DWDM) systems.

Signal Processing Capabilities

Planar lightwave circuits (PLCs) and arrayed waveguide gratings (AWGs) offer distinct signal processing capabilities essential in optical communications. PLCs provide versatile, compact integration suitable for complex signal routing, splitting, and combining with high stability and low loss. AWGs excel in precise wavelength multiplexing and demultiplexing, enabling efficient wavelength division multiplexing (WDM) with high channel count and spectral resolution, making your optical systems highly scalable and efficient.

Performance Metrics: Insertion Loss, Crosstalk, and Bandwidth

Planar lightwave circuits (PLCs) typically exhibit lower insertion loss and more consistent crosstalk levels compared to arrayed waveguide gratings (AWGs), enhancing signal integrity in high-density optical networks. AWGs offer wider bandwidth capabilities, making them suitable for applications requiring broader wavelength channels, but may sacrifice some performance in crosstalk and insertion loss due to complex waveguide structures. Choosing between PLC and AWG depends on optimizing your system's specific performance needs in terms of insertion loss, crosstalk, and bandwidth efficiency.

Scalability and Channel Count

Planar lightwave circuits (PLCs) offer high scalability with the ability to integrate a large number of channels in a compact footprint, making them ideal for dense wavelength division multiplexing (DWDM) systems. Arrayed waveguide gratings (AWGs) provide precise channel spacing and stable performance but can face limitations when scaling beyond 80 to 160 channels due to increased insertion loss and crosstalk. Your choice between PLC and AWG depends on the required channel count, where PLCs excel in supporting higher scalability for complex optical networks.

Application Areas in Optical Networks

Planar lightwave circuits (PLCs) and arrayed waveguide gratings (AWGs) are essential components in optical networks, serving distinct application areas based on their design and functionality. PLCs are widely used in passive optical networks (PONs) and wavelength-division multiplexing (WDM) systems for signal splitting, combining, and routing due to their compact size and reliability. Your network can benefit from AWGs in high-capacity WDM transmission, where precise wavelength multiplexing and demultiplexing enable efficient channel management and scalability.

Cost Considerations and Manufacturing Complexity

Planar lightwave circuits (PLCs) generally offer lower manufacturing complexity and reduced costs due to their simpler fabrication processes using silica-on-silicon technology, which supports mass production and integration. Arrayed waveguide gratings (AWGs), while providing precise wavelength multiplexing, involve more intricate design and fabrication steps, increasing production costs and requiring tighter tolerances to maintain performance. The cost-effectiveness of PLCs makes them preferable for large-scale deployments, whereas AWGs are typically chosen for applications demanding higher spectral resolution despite higher manufacturing expenses.

Reliability and Environmental Stability

Planar lightwave circuits (PLCs) exhibit higher reliability and superior environmental stability compared to Arrayed Waveguide Gratings (AWGs), due to their robust silica-based fabrication and reduced sensitivity to temperature fluctuations. Your optical network benefits from PLC's consistent performance under varying humidity, temperature changes, and mechanical stress, minimizing signal degradation and maintenance needs. AWGs, often more susceptible to environmental factors, may require additional temperature control to maintain optimal functionality in harsh settings.

Future Trends and Developments in PLC and AWG Technologies

Future trends in Planar Lightwave Circuit (PLC) technology emphasize increased integration density, lower insertion loss, and enhanced thermal stability to meet growing demands in optical networking. Arrayed Waveguide Grating (AWG) developments focus on improved wavelength selectivity, reduced crosstalk, and tunable capabilities for dynamic wavelength routing in next-generation data centers and telecom infrastructures. Innovations such as hybrid PLC-AWG devices and photonic integration circuits are poised to drive advancements in scalability, cost-efficiency, and performance for optical communication systems.

Planar lightwave circuit vs AWG Infographic

electrown.com

electrown.com