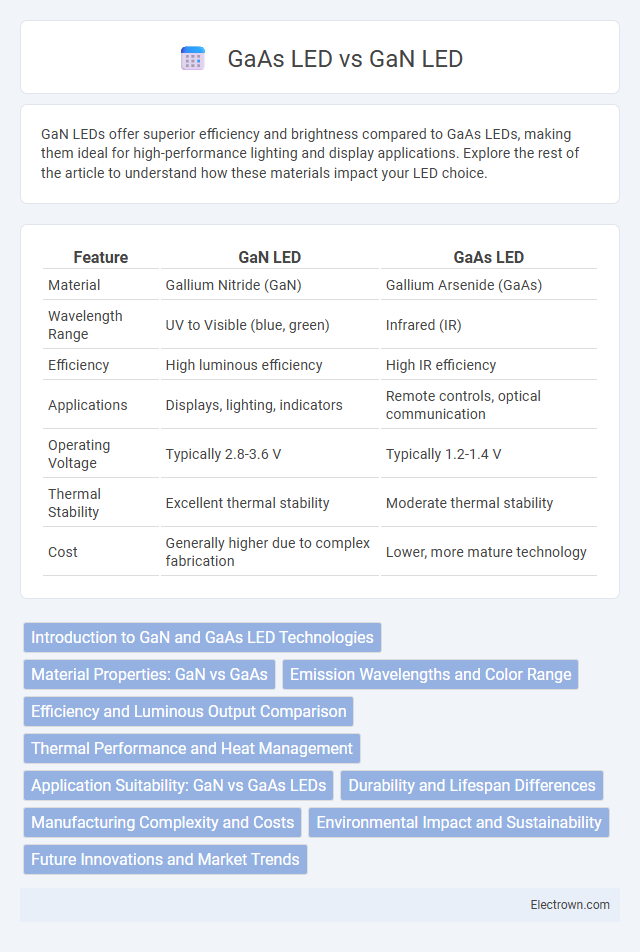

GaN LEDs offer superior efficiency and brightness compared to GaAs LEDs, making them ideal for high-performance lighting and display applications. Explore the rest of the article to understand how these materials impact your LED choice.

Table of Comparison

| Feature | GaN LED | GaAs LED |

|---|---|---|

| Material | Gallium Nitride (GaN) | Gallium Arsenide (GaAs) |

| Wavelength Range | UV to Visible (blue, green) | Infrared (IR) |

| Efficiency | High luminous efficiency | High IR efficiency |

| Applications | Displays, lighting, indicators | Remote controls, optical communication |

| Operating Voltage | Typically 2.8-3.6 V | Typically 1.2-1.4 V |

| Thermal Stability | Excellent thermal stability | Moderate thermal stability |

| Cost | Generally higher due to complex fabrication | Lower, more mature technology |

Introduction to GaN and GaAs LED Technologies

GaN LED technology utilizes gallium nitride semiconductors known for their high efficiency and brightness in blue and ultraviolet light emission, making them ideal for energy-saving applications and advanced displays. GaAs LED technology, based on gallium arsenide semiconductors, excels in infrared and near-infrared light emission, commonly used in optical communication and sensing devices. Your choice between GaN and GaAs LEDs depends on the required wavelength range and application performance needs.

Material Properties: GaN vs GaAs

Gallium Nitride (GaN) exhibits a wide bandgap of approximately 3.4 eV, enabling efficient operation in the ultraviolet to blue light spectrum, with superior thermal stability and high electron mobility compared to Gallium Arsenide (GaAs), which has a narrower bandgap of about 1.42 eV suitable for infrared to near-infrared applications. GaN's high breakdown voltage and chemical robustness contribute to its use in high-power, high-frequency optoelectronic devices, while GaAs offers advantages in electron mobility and direct bandgap properties favorable for laser diodes and photodetectors. The intrinsic material differences drive the selection of GaN LEDs for blue and UV emission and GaAs LEDs for applications requiring infrared wavelengths and faster electronic response.

Emission Wavelengths and Color Range

GaN LEDs typically emit light in the blue to ultraviolet spectrum, ranging approximately from 360 nm to 480 nm, making them ideal for applications requiring high-energy photons such as blue and green lighting. GaAs LEDs emit primarily in the near-infrared to infrared region, with wavelengths usually between 850 nm and 940 nm, which are suitable for optical communication and remote control devices. The distinct emission wavelengths of GaN and GaAs LEDs determine their color range and application domains, with GaN favored for visible light illumination and GaAs for infrared technologies.

Efficiency and Luminous Output Comparison

GaN LEDs exhibit higher efficiency and greater luminous output compared to GaAs LEDs due to their superior electron mobility and wider bandgap, which enables more effective blue and green light emission. GaN LEDs typically achieve luminous efficiency above 200 lumens per watt, whereas GaAs LEDs are generally less efficient, producing lower brightness and more heat. Your choice of LED technology significantly impacts energy savings and brightness, with GaN LEDs offering enhanced performance in lighting applications.

Thermal Performance and Heat Management

GaN LEDs exhibit superior thermal performance compared to GaAs LEDs due to their wide bandgap, which allows operation at higher temperatures with less efficiency droop. The high thermal conductivity of GaN substrates enhances heat dissipation, reducing hotspot formation and improving device reliability. In contrast, GaAs LEDs have lower thermal conductivity and are more prone to heat accumulation, necessitating more complex heat management solutions to maintain performance.

Application Suitability: GaN vs GaAs LEDs

GaN LEDs excel in high-brightness lighting and display technologies due to their wide bandgap and high efficiency in the blue and ultraviolet spectrum, making them ideal for applications requiring intense, durable light. GaAs LEDs are primarily suited for infrared applications such as remote controls and fiber-optic communication because of their narrow bandgap and efficient emission in the near-infrared spectral range. The choice between GaN and GaAs LEDs depends on the required wavelength and intensity, with GaN favored for visible and ultraviolet light and GaAs for infrared light applications.

Durability and Lifespan Differences

GaN LEDs exhibit superior durability compared to GaAs LEDs due to their robust crystal structure and higher thermal conductivity, which allows them to operate efficiently under high temperatures without rapid degradation. The lifespan of GaN LEDs typically exceeds 50,000 hours, significantly outlasting GaAs LEDs, which generally have shorter service lives because of their susceptibility to oxidation and thermal stress. Choosing GaN LED technology ensures your lighting device remains reliable and long-lasting, reducing maintenance and replacement costs.

Manufacturing Complexity and Costs

GaN LEDs involve more complex manufacturing processes due to high-temperature epitaxial growth on sapphire or silicon carbide substrates, resulting in higher production costs. GaAs LEDs benefit from mature fabrication techniques with lower thermal budgets, enabling cost-effective mass production. The substrate material and heteroepitaxial challenges make GaN LEDs generally more expensive to produce compared to GaAs LEDs.

Environmental Impact and Sustainability

GaN LEDs exhibit significantly lower environmental impact compared to GaAs LEDs due to their higher energy efficiency and longer lifespan, which reduce electronic waste and energy consumption. Gallium Nitride's non-toxic composition contrasts with the toxic arsenic in GaAs LEDs, minimizing hazardous waste and improving sustainability in manufacturing and disposal processes. The use of GaN technology supports greener lighting solutions aligned with global efforts to reduce carbon emissions and promote sustainable electronic materials.

Future Innovations and Market Trends

GaN LED technology is driving future innovations with its superior energy efficiency, higher brightness, and longer lifespan compared to GaAs LEDs, making it ideal for applications in displays, automotive lighting, and UV sterilization. Market trends indicate a growing demand for GaN LEDs due to their cost-effectiveness and scalability in mass production, while GaAs LEDs remain relevant in niche sectors requiring infrared and high-speed communication solutions. Your investment in GaN LED technology aligns with the rapid expansion of smart devices and green energy sectors anticipating substantial growth in the coming years.

GaN LED vs GaAs LED Infographic

electrown.com

electrown.com