Distributed Bragg reflectors (DBRs) offer high reflectivity with low absorption by using multiple dielectric layers to create constructive interference, making them ideal for applications requiring precise wavelength control and minimal energy loss. Explore the rest of this article to understand how Your choice between DBRs and metallic mirrors can impact performance in optics and photonics.

Table of Comparison

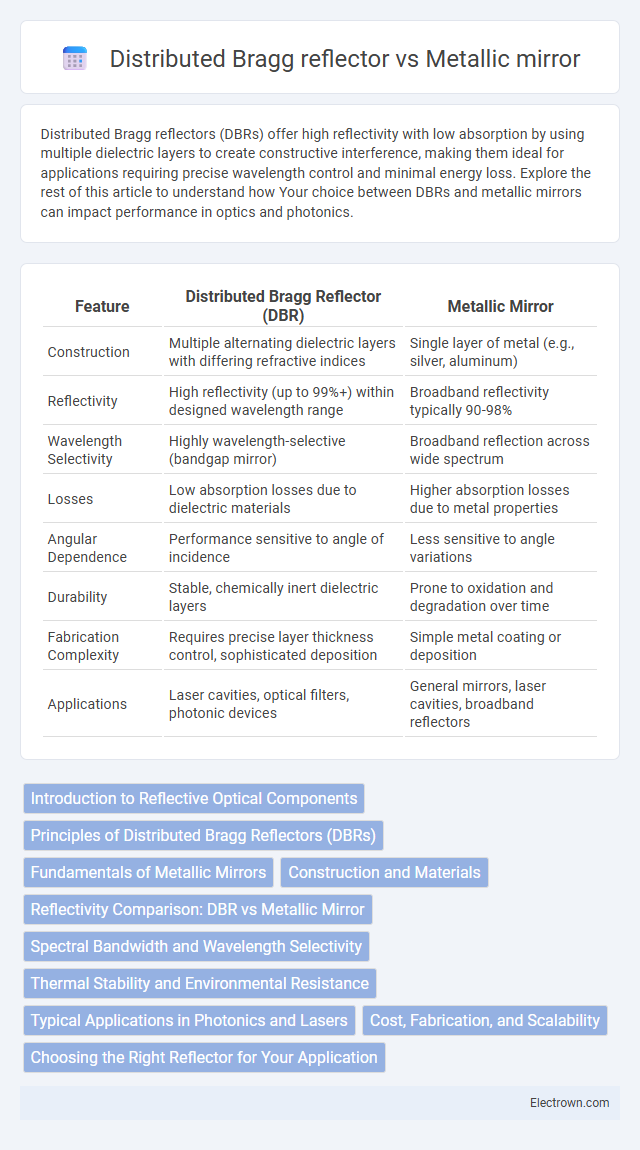

| Feature | Distributed Bragg Reflector (DBR) | Metallic Mirror |

|---|---|---|

| Construction | Multiple alternating dielectric layers with differing refractive indices | Single layer of metal (e.g., silver, aluminum) |

| Reflectivity | High reflectivity (up to 99%+) within designed wavelength range | Broadband reflectivity typically 90-98% |

| Wavelength Selectivity | Highly wavelength-selective (bandgap mirror) | Broadband reflection across wide spectrum |

| Losses | Low absorption losses due to dielectric materials | Higher absorption losses due to metal properties |

| Angular Dependence | Performance sensitive to angle of incidence | Less sensitive to angle variations |

| Durability | Stable, chemically inert dielectric layers | Prone to oxidation and degradation over time |

| Fabrication Complexity | Requires precise layer thickness control, sophisticated deposition | Simple metal coating or deposition |

| Applications | Laser cavities, optical filters, photonic devices | General mirrors, laser cavities, broadband reflectors |

Introduction to Reflective Optical Components

Reflective optical components like Distributed Bragg Reflectors (DBRs) use multiple dielectric layers to achieve high reflectivity through constructive interference, offering wavelength-selective performance with minimal absorption. Metallic mirrors rely on thin metal films, such as silver or aluminum, providing broadband and omnidirectional reflection but with inherent absorption losses and lower damage thresholds. The choice between DBRs and metallic mirrors impacts optical efficiency, spectral selectivity, and device durability in applications like lasers, sensors, and photonic circuits.

Principles of Distributed Bragg Reflectors (DBRs)

Distributed Bragg Reflectors (DBRs) rely on alternating layers of materials with different refractive indices to create constructive interference of reflected light waves, enhancing reflectivity at specific wavelengths. Unlike metallic mirrors that reflect light due to free electron interaction on metal surfaces, DBRs achieve high reflectivity through photonic bandgap effects within the multilayer structure. Your optical systems benefit from DBRs by achieving lower absorption losses and higher spectral selectivity compared to traditional metallic mirrors.

Fundamentals of Metallic Mirrors

Metallic mirrors function by reflecting light through the free electrons present in the metal surface, which oscillate to re-emit the incident photons. This reflection mechanism offers broad spectral reflectivity but often results in higher absorption losses compared to dielectric-based Distributed Bragg reflectors (DBRs). Your choice between a metallic mirror and a DBR depends on factors like wavelength range, reflectivity requirements, and device integration needs.

Construction and Materials

Distributed Bragg reflectors (DBRs) consist of alternating layers of dielectric materials with varying refractive indexes, such as silicon dioxide and titanium dioxide, designed to create constructive interference at specific wavelengths. Metallic mirrors, typically made from metals like aluminum, silver, or gold, rely on free electron reflection to achieve high reflectivity across broad spectral ranges. You can choose DBRs for wavelength-selective applications requiring low absorption, while metallic mirrors offer broadband reflection with simpler fabrication.

Reflectivity Comparison: DBR vs Metallic Mirror

Distributed Bragg reflectors (DBRs) achieve reflectivity levels exceeding 99% through multiple alternating dielectric layers designed to create constructive interference at specific wavelengths. Metallic mirrors, typically made from silver or aluminum, offer broadband reflectivity around 90-98% but suffer from higher absorption losses compared to DBRs. Your choice between the two depends on the need for wavelength-specific high reflectivity (favoring DBRs) or broad-spectrum reflection with simpler fabrication (favoring metallic mirrors).

Spectral Bandwidth and Wavelength Selectivity

Distributed Bragg reflectors (DBRs) exhibit narrow spectral bandwidth and high wavelength selectivity due to their multilayer dielectric structure designed to reflect specific wavelengths through constructive interference. Metallic mirrors provide broader spectral bandwidth with lower wavelength selectivity, reflecting a wide range of wavelengths but with higher absorption losses and reduced reflectivity at specific wavelengths. The choice between DBRs and metallic mirrors depends on the application's requirement for precise wavelength control versus broadband reflectivity.

Thermal Stability and Environmental Resistance

Distributed Bragg reflectors (DBRs) exhibit superior thermal stability compared to metallic mirrors, maintaining high reflectivity at elevated temperatures due to their dielectric multilayer structure. DBRs also show enhanced environmental resistance, resisting oxidation and corrosion that commonly degrade metallic mirrors over time. Metallic mirrors, often made from materials like aluminum or silver, suffer from surface oxidation and reduced reflectivity in harsh environments, limiting their long-term performance.

Typical Applications in Photonics and Lasers

Distributed Bragg reflectors (DBRs) are widely used in photonics and lasers for applications requiring high reflectivity with precise wavelength selectivity, such as vertical-cavity surface-emitting lasers (VCSELs) and optical filters. Metallic mirrors offer broadband reflectivity and durability, making them suitable for laser cavities where wavelength selectivity is less critical but high power handling and thermal stability are essential. Your choice between DBRs and metallic mirrors depends on the need for wavelength specificity versus broadband performance in your photonics or laser system.

Cost, Fabrication, and Scalability

Distributed Bragg reflectors (DBRs) offer lower fabrication costs through standard semiconductor layering techniques compared to the higher material and processing expenses of metallic mirrors. DBRs provide excellent scalability for integrated photonic devices due to their compatibility with epitaxial growth and planar processes, while metallic mirrors face challenges in uniformity and thickness control at large scales. Your choice depends on balancing DBR's precision and scalability with the simpler but less versatile nature of metallic mirrors in terms of cost-effective production.

Choosing the Right Reflector for Your Application

Distributed Bragg reflectors (DBRs) offer high reflectivity and wavelength selectivity, making them ideal for applications requiring precise optical filtering and minimal absorption, such as lasers and sensors. Metallic mirrors provide broadband reflectivity with simpler fabrication and are preferred in environments demanding durability and high thermal tolerance. Selecting the right reflector depends on balancing reflectance spectrum, fabrication complexity, and operational conditions to optimize device performance.

Distributed Bragg reflector vs Metallic mirror Infographic

electrown.com

electrown.com