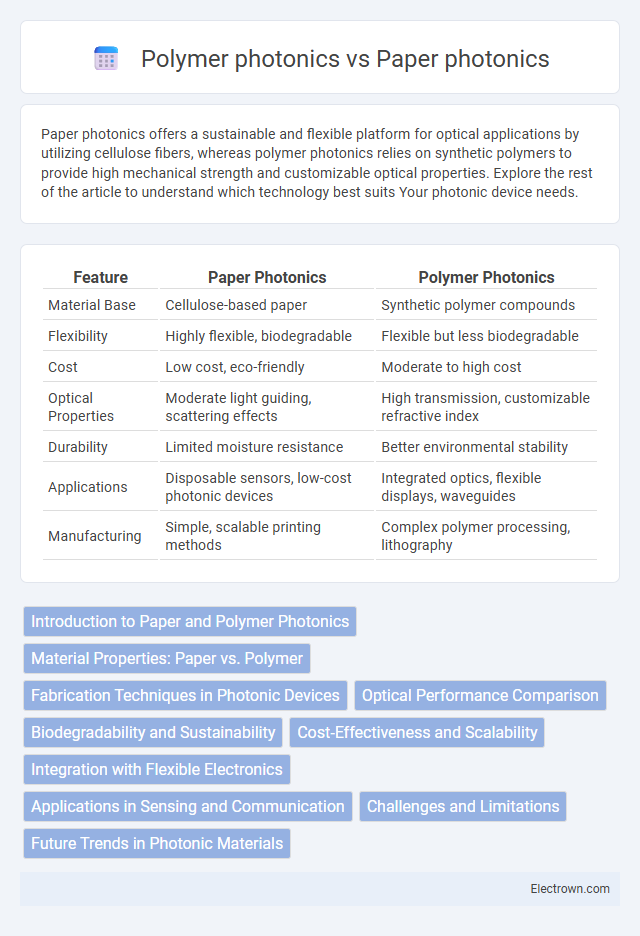

Paper photonics offers a sustainable and flexible platform for optical applications by utilizing cellulose fibers, whereas polymer photonics relies on synthetic polymers to provide high mechanical strength and customizable optical properties. Explore the rest of the article to understand which technology best suits Your photonic device needs.

Table of Comparison

| Feature | Paper Photonics | Polymer Photonics |

|---|---|---|

| Material Base | Cellulose-based paper | Synthetic polymer compounds |

| Flexibility | Highly flexible, biodegradable | Flexible but less biodegradable |

| Cost | Low cost, eco-friendly | Moderate to high cost |

| Optical Properties | Moderate light guiding, scattering effects | High transmission, customizable refractive index |

| Durability | Limited moisture resistance | Better environmental stability |

| Applications | Disposable sensors, low-cost photonic devices | Integrated optics, flexible displays, waveguides |

| Manufacturing | Simple, scalable printing methods | Complex polymer processing, lithography |

Introduction to Paper and Polymer Photonics

Paper photonics leverages cellulose-based materials to create flexible, biodegradable optical devices, making it ideal for sustainable and cost-effective applications. Polymer photonics involves synthetic polymers with customizable refractive indices and excellent optical clarity, enabling high-performance waveguides and integrated photonic circuits. Your choice depends on requirements like environmental impact, mechanical flexibility, and optical efficiency.

Material Properties: Paper vs. Polymer

Paper photonics utilizes cellulose fibers offering biodegradability, flexibility, and cost-effectiveness but exhibits lower optical clarity and mechanical durability compared to polymer photonics. Polymer photonics employs materials such as PMMA or PDMS providing superior optical transparency, higher refractive index control, and enhanced durability for advanced photonic applications. The inherent porosity and hydrophilicity of paper induce scattering losses, whereas polymers ensure low optical attenuation and precise waveguide fabrication.

Fabrication Techniques in Photonic Devices

Paper photonics employs low-cost, eco-friendly fabrication techniques such as printing, inkjet deposition, and laser patterning on cellulose-based substrates, enabling flexible and biodegradable photonic devices. Polymer photonics utilizes advanced methods like photolithography, nanoimprint lithography, and spin coating on polymer films, offering precise control over waveguide structures and high integration density. These distinct fabrication approaches impact device performance, scalability, and application scope in optical communications and sensing technologies.

Optical Performance Comparison

Paper photonics exhibits lower optical performance due to its high scattering losses and limited refractive index control, resulting in reduced light confinement and higher attenuation compared to polymer photonics. Polymer photonics offers superior optical clarity, tunable refractive indices, and enhanced waveguide uniformity, enabling efficient light transmission with minimal losses. The inherent porosity and surface roughness of paper substrates significantly hinder optical signal integrity, making polymer-based devices preferable for high-performance photonic applications.

Biodegradability and Sustainability

Paper photonics offers superior biodegradability compared to polymer photonics, as it relies on cellulose-based materials that naturally decompose without releasing harmful pollutants. Polymer photonics, often made from synthetic plastics, present challenges for sustainability due to their longer degradation periods and potential microplastic pollution. Your choice of paper photonics supports eco-friendly applications by reducing environmental impact and promoting sustainable development in photonic technologies.

Cost-Effectiveness and Scalability

Paper photonics offers superior cost-effectiveness due to its use of inexpensive, abundant cellulose materials and simple fabrication processes, enabling mass production at low expenses. Polymer photonics, while generally more costly because of complex synthetic materials and precision manufacturing techniques, provides enhanced scalability through well-established industrial processes adaptable for large-scale integration. The economic advantage of paper photonics lies in its rapid, sustainable production potential, whereas polymer photonics benefits from mature infrastructure supporting high-volume, high-performance photonic device fabrication.

Integration with Flexible Electronics

Paper photonics offers a lightweight and biodegradable platform ideal for low-cost, disposable flexible electronics, leveraging cellulose's natural flexibility and porosity to integrate optoelectronic components seamlessly. Polymer photonics provides superior mechanical durability, chemical stability, and customizable refractive indices, enabling more robust and long-lasting integration with flexible electronic devices used in wearable technology and advanced sensors. Your choice between paper and polymer photonics should consider the application's lifespan and environmental impact, balancing sustainability with performance requirements.

Applications in Sensing and Communication

Paper photonics offers lightweight, flexible, and biodegradable platforms ideal for low-cost, disposable sensors in environmental monitoring and healthcare, providing rapid, on-site diagnostic capabilities. Polymer photonics excels in robust, durable, and highly tunable optical components used in telecommunications and long-range sensing, ensuring high signal fidelity and integration with existing fiber networks. Your choice between paper and polymer photonics depends on the application's durability requirements and environmental impact considerations.

Challenges and Limitations

Paper photonics faces significant challenges including low mechanical stability, poor moisture resistance, and limited optical performance due to the inherent porosity and rough surface of cellulose fibers. Polymer photonics, while offering better flexibility and optical clarity, encounters limitations related to thermal sensitivity, material degradation over time, and complex fabrication processes that increase production costs. Both technologies struggle with scalability and integration into existing optical systems, necessitating ongoing innovation in material science and engineering.

Future Trends in Photonic Materials

Future trends in photonic materials emphasize advancements in both paper photonics and polymer photonics, with a growing focus on sustainability and flexibility. Polymer photonics offer exceptional durability and tunable optical properties, making them ideal for next-generation wearable devices and flexible displays. You can expect continued innovation in biodegradable paper photonics for eco-friendly optical sensors and communication technologies, combining cost-effectiveness with environmental benefits.

Paper photonics vs Polymer photonics Infographic

electrown.com

electrown.com