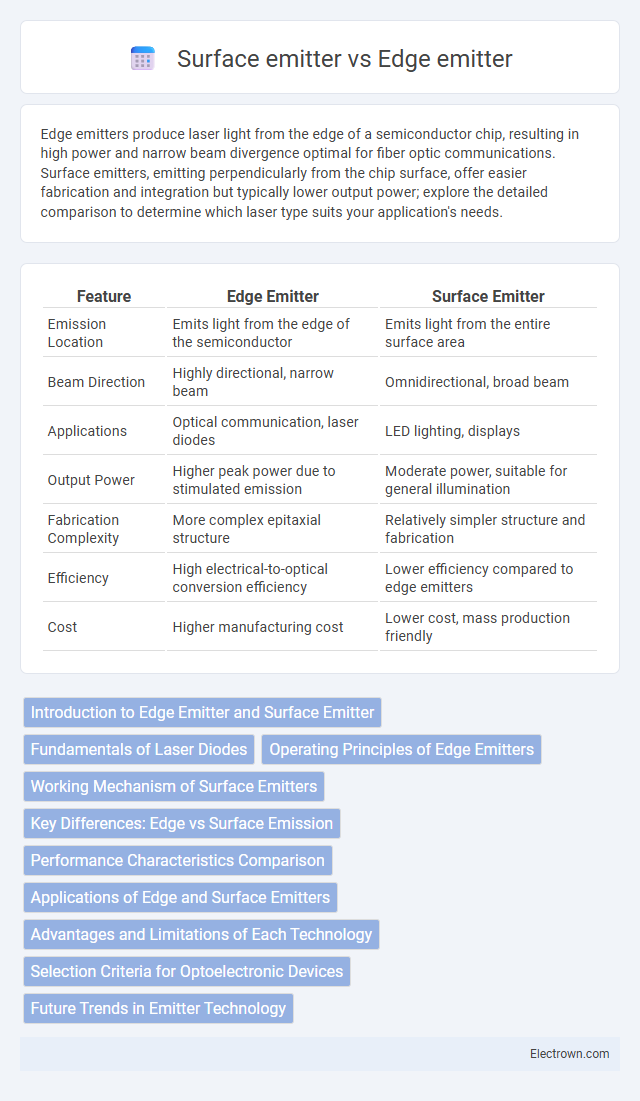

Edge emitters produce laser light from the edge of a semiconductor chip, resulting in high power and narrow beam divergence optimal for fiber optic communications. Surface emitters, emitting perpendicularly from the chip surface, offer easier fabrication and integration but typically lower output power; explore the detailed comparison to determine which laser type suits your application's needs.

Table of Comparison

| Feature | Edge Emitter | Surface Emitter |

|---|---|---|

| Emission Location | Emits light from the edge of the semiconductor | Emits light from the entire surface area |

| Beam Direction | Highly directional, narrow beam | Omnidirectional, broad beam |

| Applications | Optical communication, laser diodes | LED lighting, displays |

| Output Power | Higher peak power due to stimulated emission | Moderate power, suitable for general illumination |

| Fabrication Complexity | More complex epitaxial structure | Relatively simpler structure and fabrication |

| Efficiency | High electrical-to-optical conversion efficiency | Lower efficiency compared to edge emitters |

| Cost | Higher manufacturing cost | Lower cost, mass production friendly |

Introduction to Edge Emitter and Surface Emitter

Edge emitters generate laser light from the cleaved edge of a semiconductor chip, producing a narrow, highly directional beam with high power efficiency and excellent beam quality. Surface emitters, such as Vertical-Cavity Surface-Emitting Lasers (VCSELs), emit light perpendicular to the chip surface, enabling two-dimensional arrays and simpler packaging for applications in communication and sensing. Both types are critical in photonic devices, with edge emitters preferred for high-power, long-distance communication and surface emitters favored for cost-effective, scalable optical systems.

Fundamentals of Laser Diodes

Edge emitter laser diodes generate light by emitting photons from the edge of the semiconductor chip where the p-n junction is cleaved, enabling high power and narrow emission profiles suitable for fiber optics and communications. Surface emitter laser diodes, such as VCSELs (Vertical-Cavity Surface-Emitting Lasers), emit light perpendicular to the semiconductor surface, offering advantages in array fabrication, lower manufacturing costs, and better beam quality for short-distance data transmission. Understanding these fundamental emission mechanisms helps you select the appropriate laser diode type based on your application's power, beam shape, and integration requirements.

Operating Principles of Edge Emitters

Edge emitters operate by injecting current into a semiconductor material, where light is generated through stimulated emission and guided along the plane of the chip via total internal reflection. The emitted light exits from the cleaved edge of the chip, allowing for efficient coupling into optical fibers or other waveguides. Understanding the operating principles of edge emitters can help optimize Your optical communication systems for higher power and narrower beam divergence.

Working Mechanism of Surface Emitters

Surface emitters operate by emitting light perpendicular to the wafer surface through a vertical cavity structure, utilizing distributed Bragg reflectors (DBRs) to form an optical resonator. This vertical-cavity surface-emitting laser (VCSEL) uses multiple quantum wells as the gain medium, where carriers recombine to generate coherent light that escapes through the top surface. The emission characteristics enable high beam quality and easy integration into 2D arrays, distinguishing surface emitters from edge emitters that emit from the cleaved edge of the chip.

Key Differences: Edge vs Surface Emission

Edge emitters generate laser light from the cleaved edge of a semiconductor chip, producing a narrow, highly directional beam ideal for fiber optic communications. Surface emitters, such as VCSELs (Vertical-Cavity Surface-Emitting Lasers), emit light perpendicular to the chip surface, enabling easier testing, two-dimensional arrays, and lower manufacturing costs. Key differences include beam shape, directionality, fabrication complexity, and application suitability, with edge emitters excelling in high-power, long-distance transmission and surface emitters favored for compact, low-cost optical interconnects.

Performance Characteristics Comparison

Edge emitters typically offer higher power efficiency and narrower spectral linewidths, making them ideal for applications requiring precise wavelength stability and high modulation speeds. Surface emitters provide superior beam quality with circular emission patterns and easier integration into optical systems, benefiting applications demanding compactness and vertical emission. Your choice depends on whether you prioritize power output and spectral purity with edge emitters or beam profile and integration convenience with surface emitters.

Applications of Edge and Surface Emitters

Edge emitters are primarily used in fiber optic communications due to their high power output and efficient coupling with optical fibers, making them ideal for long-distance data transmission and telecommunications. Surface emitters, such as vertical-cavity surface-emitting lasers (VCSELs), find applications in data centers, consumer electronics, and sensing technologies because of their compact size, ease of testing on wafer, and ability to form dense two-dimensional arrays. Both types of emitters play crucial roles in areas like high-speed internet, LIDAR systems, and optical interconnects, leveraging their unique emission characteristics to optimize performance in specific use cases.

Advantages and Limitations of Each Technology

Edge emitters offer high power density and narrow spectral width, making them ideal for telecommunications and sensing applications requiring precise wavelength control. Surface emitters provide easier fabrication and integration with planar arrays, benefiting applications like LiDAR and optical interconnects, although they generally have lower output power and broader spectral linewidth. Edge emitters face challenges with packaging and beam shaping, while surface emitters are limited by lower efficiency and more complex thermal management.

Selection Criteria for Optoelectronic Devices

Edge emitters offer higher power output and narrow beam divergence, making them suitable for long-distance fiber optic communication, while surface emitters provide simpler coupling with planar lightwave circuits and cost-effective mass production. Your selection criteria should consider factors like emission wavelength, beam quality, device efficiency, and integration compatibility to ensure optimal performance. Thermal management and modulation speed also play critical roles in choosing between edge and surface emitters for specific optoelectronic applications.

Future Trends in Emitter Technology

Edge emitters are evolving with advances in nanofabrication, enabling higher power density and improved beam quality tailored for telecommunications and LiDAR applications. Surface emitters benefit from wafer-scale integration and lower manufacturing costs, driving innovation in 3D sensing and optical interconnects. Future trends emphasize hybrid designs combining edge emitter efficiency with surface emitter scalability to meet demands in high-speed data transmission and photonic integrated circuits.

Edge emitter vs Surface emitter Infographic

electrown.com

electrown.com