A Distributed Bragg Reflector (DBR) uses multiple alternating layers of dielectric materials to achieve high reflectivity through constructive interference, providing low absorption and precise wavelength selectivity, whereas a metal mirror relies on free electron reflection on a metal surface, offering broadband reflectivity but higher losses due to absorption. To understand which reflector best suits your optical application, explore the detailed comparison in the rest of this article.

Table of Comparison

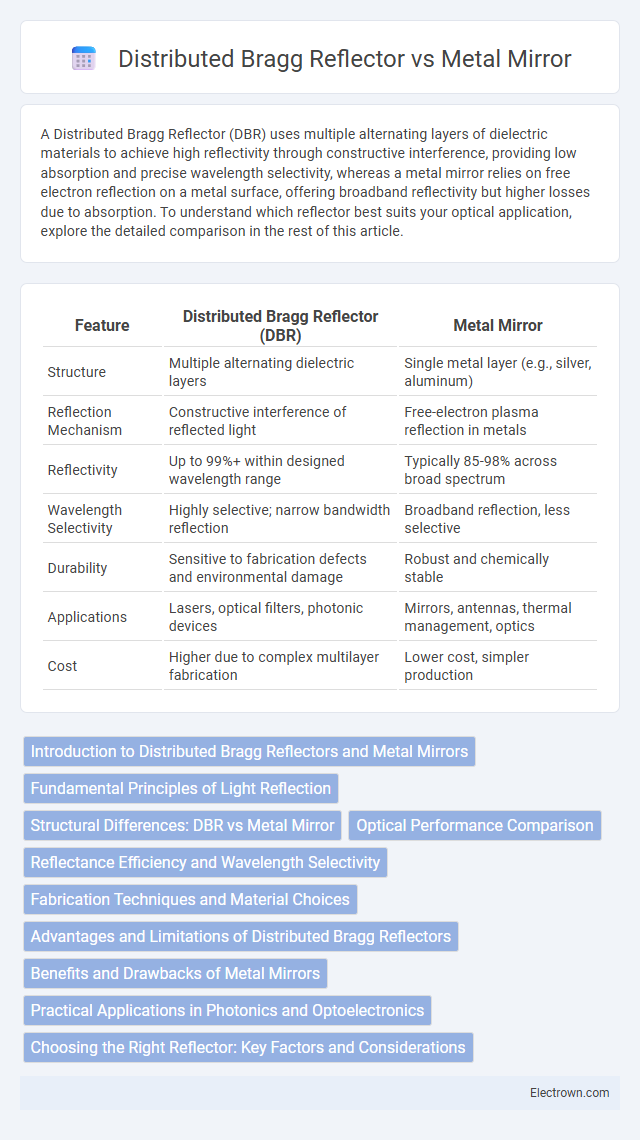

| Feature | Distributed Bragg Reflector (DBR) | Metal Mirror |

|---|---|---|

| Structure | Multiple alternating dielectric layers | Single metal layer (e.g., silver, aluminum) |

| Reflection Mechanism | Constructive interference of reflected light | Free-electron plasma reflection in metals |

| Reflectivity | Up to 99%+ within designed wavelength range | Typically 85-98% across broad spectrum |

| Wavelength Selectivity | Highly selective; narrow bandwidth reflection | Broadband reflection, less selective |

| Durability | Sensitive to fabrication defects and environmental damage | Robust and chemically stable |

| Applications | Lasers, optical filters, photonic devices | Mirrors, antennas, thermal management, optics |

| Cost | Higher due to complex multilayer fabrication | Lower cost, simpler production |

Introduction to Distributed Bragg Reflectors and Metal Mirrors

Distributed Bragg Reflectors (DBRs) consist of multiple alternating layers of dielectric materials with varying refractive indices, designed to reflect specific wavelengths of light through constructive interference. Metal mirrors rely on the free electrons in metals like silver or aluminum to reflect a broad spectrum of light with high reflectivity but limited spectral selectivity. DBRs offer precise wavelength control and low absorption losses, while metal mirrors provide broadband reflection and durability in optical applications.

Fundamental Principles of Light Reflection

Distributed Bragg reflectors (DBRs) operate on the principle of constructive interference caused by alternating layers of materials with different refractive indices, reflecting specific wavelengths of light with high efficiency. Metal mirrors rely on the free electrons in metals to reflect light through electromagnetic wave interactions, resulting in broadband reflection but with higher absorption losses. DBRs offer superior wavelength selectivity and lower absorption compared to metal mirrors, making them ideal for precise optical applications.

Structural Differences: DBR vs Metal Mirror

Distributed Bragg Reflectors (DBRs) consist of multiple alternating layers of dielectric materials with varying refractive indices, creating constructive interference for specific wavelengths through periodic thickness design. Metal mirrors are composed of a single reflective metallic layer, such as silver or aluminum, relying on free electron oscillations to reflect a broad range of wavelengths. The structural difference lies in DBRs' multilayer dielectric stack versus metal mirrors' homogeneous conductive surface, impacting reflectivity bandwidth and optical absorption.

Optical Performance Comparison

Distributed Bragg reflectors (DBRs) provide high reflectivity with precise spectral selectivity, achieving reflectance values above 99% within narrow wavelength bands due to multiple alternating dielectric layers designed for constructive interference. Metal mirrors, typically made of silver or aluminum, offer broadband reflectance but suffer from lower peak reflectivity and higher absorption losses, especially in the visible and near-infrared regions. DBRs excel in applications requiring wavelength-specific control and low loss, while metal mirrors are favored for broad spectral range and simpler fabrication.

Reflectance Efficiency and Wavelength Selectivity

Distributed Bragg reflectors (DBRs) provide high reflectance efficiency exceeding 99% through constructive interference of multiple dielectric layers, offering precise wavelength selectivity tailored by layer thickness and refractive index. Metal mirrors, though generally broadband with reflectance around 90-98%, exhibit less wavelength specificity due to inherent plasmonic absorption and phase shifts at metal-dielectric interfaces. Your choice depends on whether precise wavelength control or broader spectral reflectance is prioritized in optical device applications.

Fabrication Techniques and Material Choices

Distributed Bragg reflectors (DBRs) are fabricated using precise thin-film deposition techniques such as molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD), enabling alternating layers of semiconductor materials like GaAs/AlAs or Si/SiO2 with controlled thickness for constructive interference. In contrast, metal mirrors rely on physical vapor deposition methods like sputtering or thermal evaporation to deposit metals such as silver, aluminum, or gold, offering high reflectivity but limited spectral selectivity. Material choices in DBRs prioritize refractive index contrast and lattice matching for high reflectivity and structural integrity, whereas metal mirrors emphasize conductivity and durability for broad-spectrum performance.

Advantages and Limitations of Distributed Bragg Reflectors

Distributed Bragg Reflectors (DBRs) offer high reflectivity with low optical losses, making them ideal for applications requiring precise wavelength selectivity and minimal absorption, such as in lasers and optical filters. Their layered dielectric structure enables tailored reflectance spectra but limits their operational bandwidth and angular tolerance compared to metal mirrors. You can leverage DBRs for efficient light confinement, though their fabrication complexity and sensitivity to environmental variations may present challenges.

Benefits and Drawbacks of Metal Mirrors

Metal mirrors offer high reflectivity across a broad wavelength range, making them ideal for applications requiring broadband reflection. Their robustness and easy fabrication are benefits compared to Distributed Bragg Reflectors (DBRs), which require precise layer deposition and are wavelength-specific. You should consider drawbacks such as higher absorption losses and potential surface oxidation when choosing metal mirrors over DBRs for optical systems.

Practical Applications in Photonics and Optoelectronics

Distributed Bragg reflectors (DBRs) offer high reflectivity and wavelength selectivity, making them essential in vertical-cavity surface-emitting lasers (VCSELs), optical filters, and waveguides for photonics. Metal mirrors, with their broadband reflectivity and excellent conductivity, are commonly used in plasmonic devices, photodetectors, and terahertz optoelectronics. Your choice between DBR and metal mirrors depends on the required spectral properties, device integration, and thermal stability in photonics and optoelectronics applications.

Choosing the Right Reflector: Key Factors and Considerations

Choosing between a Distributed Bragg Reflector (DBR) and a Metal Mirror hinges on factors like reflectivity, bandwidth, and fabrication complexity. DBRs provide high reflectivity with low absorption over specific wavelength ranges, making them ideal for applications requiring precise optical control and minimal losses. Your choice should align with the intended spectral range, durability requirements, and overall device integration to ensure optimal performance.

Distributed Bragg reflector vs Metal mirror Infographic

electrown.com

electrown.com