Vertical emission lasers emit light perpendicular to the surface of the semiconductor chip, enabling efficient coupling with optical fibers and compact device integration. Understanding the differences between vertical and edge emission can help you choose the best laser type for your application; read on to explore their performance, advantages, and use cases.

Table of Comparison

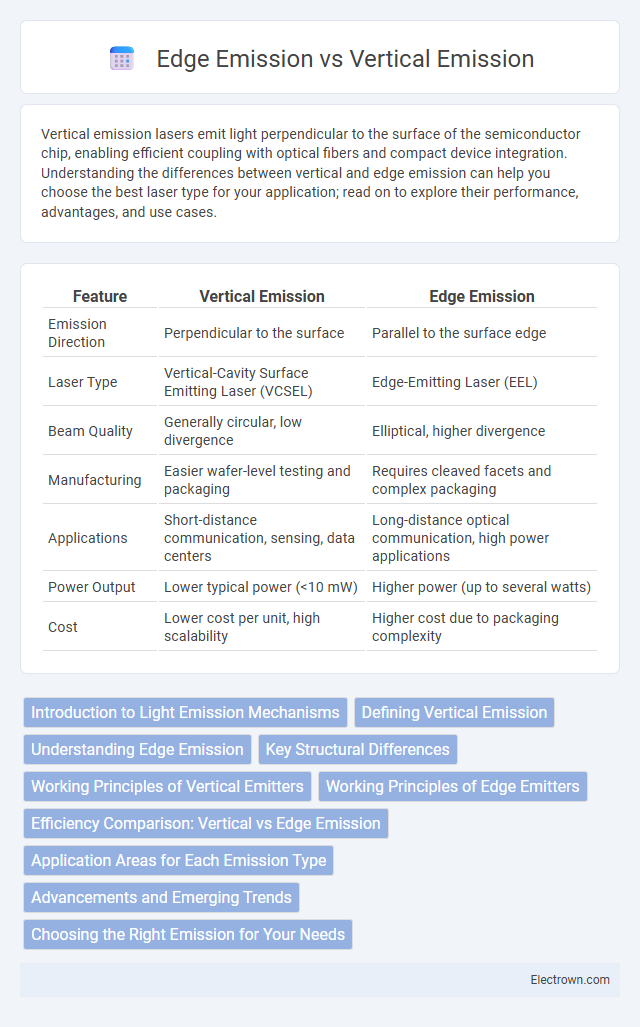

| Feature | Vertical Emission | Edge Emission |

|---|---|---|

| Emission Direction | Perpendicular to the surface | Parallel to the surface edge |

| Laser Type | Vertical-Cavity Surface Emitting Laser (VCSEL) | Edge-Emitting Laser (EEL) |

| Beam Quality | Generally circular, low divergence | Elliptical, higher divergence |

| Manufacturing | Easier wafer-level testing and packaging | Requires cleaved facets and complex packaging |

| Applications | Short-distance communication, sensing, data centers | Long-distance optical communication, high power applications |

| Power Output | Lower typical power (<10 mW) | Higher power (up to several watts) |

| Cost | Lower cost per unit, high scalability | Higher cost due to packaging complexity |

Introduction to Light Emission Mechanisms

Vertical emission and edge emission describe two primary light emission mechanisms in semiconductor laser diodes, where vertical emission directs light perpendicularly from the surface, and edge emission outputs light along the plane of the semiconductor junction. Vertical cavity surface emitting lasers (VCSELs) utilize vertical emission, enabling efficient coupling with optical fibers and high-density arrays, while edge-emitting lasers provide higher output power and beam quality due to their longer cavity geometry. Understanding these mechanisms helps you select the appropriate laser type for applications in optical communication, sensing, or imaging.

Defining Vertical Emission

Vertical emission refers to light that is emitted perpendicular to the surface of a semiconductor device, commonly found in vertical-cavity surface-emitting lasers (VCSELs). This type of emission offers advantages such as easier coupling with optical fibers and improved beam quality compared to edge emission, where light exits parallel to the wafer surface. Your choice of vertical emission devices can significantly enhance performance in applications requiring precise and efficient light output.

Understanding Edge Emission

Edge emission occurs when light is emitted from the side of a semiconductor laser, typically along the plane of the active layer, resulting in a highly directional output suitable for fiber optic communications. This method contrasts with vertical emission, where light is emitted perpendicular to the semiconductor surface, often leading to less efficient coupling in waveguide applications. Understanding edge emission is crucial for optimizing laser diode designs to achieve higher power, better beam quality, and improved modulation speeds in optical communication systems.

Key Structural Differences

Vertical emission lasers emit light perpendicular to the surface of the semiconductor wafer through distributed Bragg reflectors, enabling compact device integration with efficient heat dissipation. Edge emission lasers direct light along the plane of the wafer, utilizing cleaved or etched mirrors to define the cavity, which supports high-power output and longer cavity lengths. The key structural difference lies in the orientation of the optical cavity and emission direction, impacting device applications and fabrication complexity.

Working Principles of Vertical Emitters

Vertical emission lasers operate by directing light perpendicular to the surface of the semiconductor chip through multiple quantum well layers, enabling efficient vertical light extraction. These devices utilize the distributed Bragg reflector (DBR) mirrors within the epitaxial structure to achieve high reflectivity and mode confinement, enhancing laser performance. Vertical-cavity surface-emitting lasers (VCSELs) demonstrate lower threshold currents and easier array integration compared to edge emitters emitting light from the chip sides.

Working Principles of Edge Emitters

Edge emitters operate by generating light within a semiconductor active region, where the emitted photons travel parallel to the wafer surface and exit from the device's cleaved edge. This design enables efficient light amplification through stimulated emission confined by reflective facets, producing a coherent beam with high intensity and narrow divergence. The waveguide structure in edge emitters ensures effective mode confinement, resulting in superior performance for applications such as fiber optic communication and laser printing.

Efficiency Comparison: Vertical vs Edge Emission

Vertical emission lasers offer higher efficiency due to their shorter cavity lengths and better heat dissipation, resulting in lower threshold currents and improved modulation speeds. Edge emission lasers typically suffer from higher optical losses and less effective heat management, reducing their overall power conversion efficiency. Consequently, vertical emission devices are preferred in applications requiring high-speed and energy-efficient light sources.

Application Areas for Each Emission Type

Vertical emission lasers are widely used in data communication, optical sensing, and laser printing due to their high beam quality and ease of integration with vertical cavity surface-emitting laser (VCSEL) arrays. Edge emission lasers find applications in fiber optic communications and high-power laser systems, where their lateral emission profile enables efficient coupling with optical fibers. Industrial manufacturing, medical devices, and military systems benefit from the high output power and narrow beam divergence characteristic of edge-emitting laser diodes.

Advancements and Emerging Trends

Vertical emission lasers have seen significant advancements in efficiency and beam quality due to novel nano-fabrication techniques that enhance vertical cavity surface-emitting laser (VCSEL) performance. Emerging trends emphasize integrating VCSEL arrays with photonic integrated circuits to enable high-speed data communication and LiDAR applications. Your choice between vertical and edge emission devices depends on specific application needs such as footprint, power output, and thermal management.

Choosing the Right Emission for Your Needs

Vertical emission lasers offer a compact design with high beam quality ideal for precise applications like optical communications, while edge emission lasers deliver higher output power suited for industrial and medical uses. When choosing the right emission type for your needs, consider factors such as power requirements, beam shape, and device integration compatibility. Your decision should balance performance specifications and application environment to maximize efficiency and effectiveness.

Vertical emission vs Edge emission Infographic

electrown.com

electrown.com