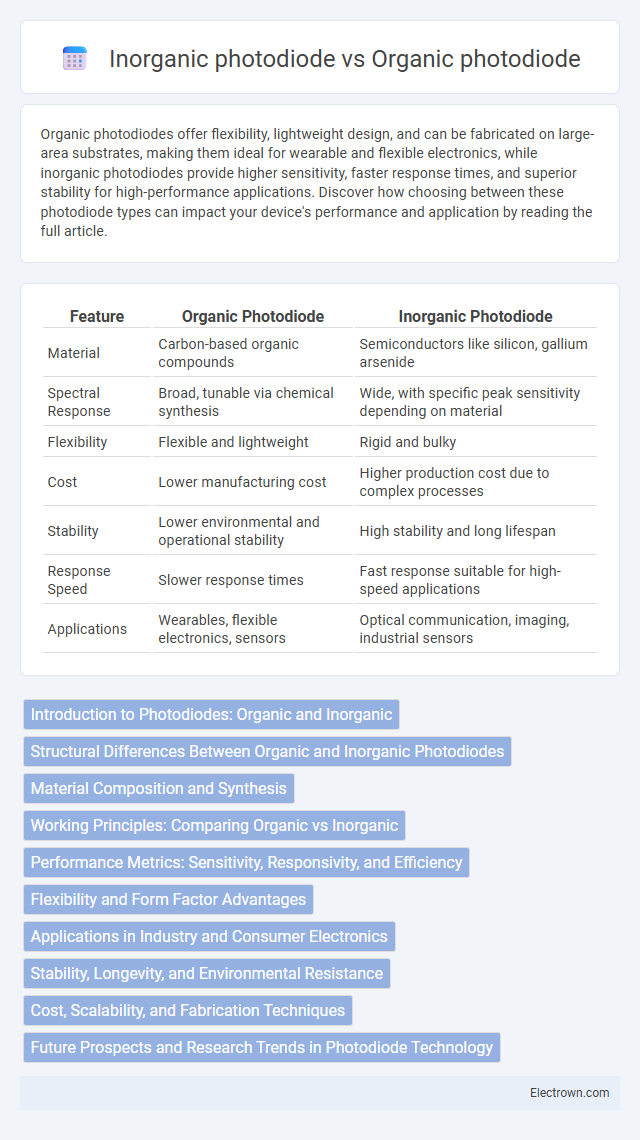

Organic photodiodes offer flexibility, lightweight design, and can be fabricated on large-area substrates, making them ideal for wearable and flexible electronics, while inorganic photodiodes provide higher sensitivity, faster response times, and superior stability for high-performance applications. Discover how choosing between these photodiode types can impact your device's performance and application by reading the full article.

Table of Comparison

| Feature | Organic Photodiode | Inorganic Photodiode |

|---|---|---|

| Material | Carbon-based organic compounds | Semiconductors like silicon, gallium arsenide |

| Spectral Response | Broad, tunable via chemical synthesis | Wide, with specific peak sensitivity depending on material |

| Flexibility | Flexible and lightweight | Rigid and bulky |

| Cost | Lower manufacturing cost | Higher production cost due to complex processes |

| Stability | Lower environmental and operational stability | High stability and long lifespan |

| Response Speed | Slower response times | Fast response suitable for high-speed applications |

| Applications | Wearables, flexible electronics, sensors | Optical communication, imaging, industrial sensors |

Introduction to Photodiodes: Organic and Inorganic

Photodiodes are semiconductor devices that convert light into electrical current, with organic photodiodes (OPDs) utilizing carbon-based materials and inorganic photodiodes typically using silicon or other crystalline semiconductors. Organic photodiodes offer advantages such as mechanical flexibility, lightweight, and tunable absorption spectra suitable for low-cost, large-area applications, while inorganic photodiodes exhibit higher sensitivity, faster response times, and better stability under harsh environmental conditions. The choice between organic and inorganic photodiodes depends on application-specific requirements such as wavelength range, device flexibility, cost, and operational durability.

Structural Differences Between Organic and Inorganic Photodiodes

Organic photodiodes consist of carbon-based semiconductor materials arranged in flexible, thin-film layers, enabling lightweight and bendable devices. Inorganic photodiodes are composed of crystalline semiconductor materials like silicon or gallium arsenide, featuring rigid, bulky structures with high electron mobility. The molecular organization in organic photodiodes facilitates tunable optoelectronic properties, whereas inorganic photodiodes offer superior charge carrier transport due to their ordered crystal lattices.

Material Composition and Synthesis

Organic photodiodes are composed of carbon-based polymers or small molecules, synthesized through solution-based processes like spin coating or inkjet printing, which allow for flexible and low-cost fabrication. Inorganic photodiodes typically use crystalline semiconductors such as silicon or gallium arsenide, grown via high-temperature methods like chemical vapor deposition or molecular beam epitaxy, resulting in rigid, high-performance devices. The material composition directly influences the synthesis technique, with organic devices favoring scalable, low-energy methods and inorganic devices requiring precise, energy-intensive crystal growth.

Working Principles: Comparing Organic vs Inorganic

Organic photodiodes operate based on the photoinduced charge separation within organic semiconductor materials, utilizing exciton diffusion and dissociation at donor-acceptor interfaces. Inorganic photodiodes rely on direct photon absorption in crystalline semiconductor substrates like silicon or gallium arsenide, generating electron-hole pairs that are separated by built-in electric fields. The differences in material properties result in organic devices exhibiting flexibility and tunable absorption spectra, whereas inorganic photodiodes typically provide higher quantum efficiency and faster response times.

Performance Metrics: Sensitivity, Responsivity, and Efficiency

Organic photodiodes exhibit moderate sensitivity and responsivity due to their tunable molecular structures but often lag behind inorganic photodiodes in efficiency and response speed. Inorganic photodiodes, such as silicon-based devices, typically offer higher sensitivity, superior responsivity across a broad spectral range, and greater quantum efficiency, making them ideal for precision applications. Your choice depends on the balance between flexibility and performance requirements, with inorganic photodiodes excelling in metrics critical for high-performance optical sensing.

Flexibility and Form Factor Advantages

Organic photodiodes offer significant flexibility and lightweight form factors, enabling seamless integration into curved or wearable devices where conventional inorganic photodiodes, typically rigid and bulky, fall short. Their thin-film, solution-processable nature allows for large-area coverage and versatile substrate compatibility, enhancing design freedom for innovative applications. You benefit from organic photodiodes when prioritizing adaptable, ergonomic sensor solutions without sacrificing performance.

Applications in Industry and Consumer Electronics

Organic photodiodes excel in flexible, lightweight applications such as wearable sensors and foldable displays due to their mechanical flexibility and cost-effective manufacturing. Inorganic photodiodes dominate high-speed, high-sensitivity tasks in industries like telecommunications, automotive LIDAR, and medical imaging, attributed to their superior quantum efficiency and stability. Your choice between organic and inorganic photodiodes depends on the specific application requirements for sensitivity, durability, and form factor in consumer electronics and industrial systems.

Stability, Longevity, and Environmental Resistance

Organic photodiodes typically exhibit lower stability and shorter longevity compared to inorganic photodiodes due to their sensitivity to moisture, oxygen, and UV exposure. Inorganic photodiodes, such as silicon-based devices, offer superior environmental resistance and durability, maintaining performance over extended periods under harsh conditions. Your choice between these photodiodes should consider the operational environment and lifespan requirements to ensure optimal device performance.

Cost, Scalability, and Fabrication Techniques

Organic photodiodes generally offer lower cost due to inexpensive materials and solution-based fabrication methods like printing, enabling large-area scalability on flexible substrates. In contrast, inorganic photodiodes, typically made from silicon or III-V semiconductors, require complex, high-temperature vacuum deposition processes, resulting in higher manufacturing costs and limited scalability. The distinction in fabrication techniques directly impacts production throughput and device integration, with organic photodiodes favoring roll-to-roll processing and inorganic counterparts excelling in high-performance, small-area applications.

Future Prospects and Research Trends in Photodiode Technology

Future prospects of organic photodiodes emphasize flexibility, low-cost fabrication, and integration with wearable electronics, driving research toward enhancing their stability and efficiency. Inorganic photodiodes continue to dominate high-performance applications due to superior sensitivity and speed, with ongoing innovations in nanostructured materials and hybrid systems. Your choice between organic and inorganic photodiodes depends on application-specific demands, balancing emerging organic materials' versatility against the established reliability of inorganic devices.

Organic photodiode vs Inorganic photodiode Infographic

electrown.com

electrown.com