Sintered and fritted glass encapsulation differ in their manufacturing processes and applications: sintered glass is created by heating powdered glass without melting, forming a porous structure ideal for filtration and diffusion, while fritted glass is made by fusing small glass particles into a solid layer, providing enhanced strength and chemical resistance. Explore this article to understand how choosing the right glass encapsulation can improve your project's performance and durability.

Table of Comparison

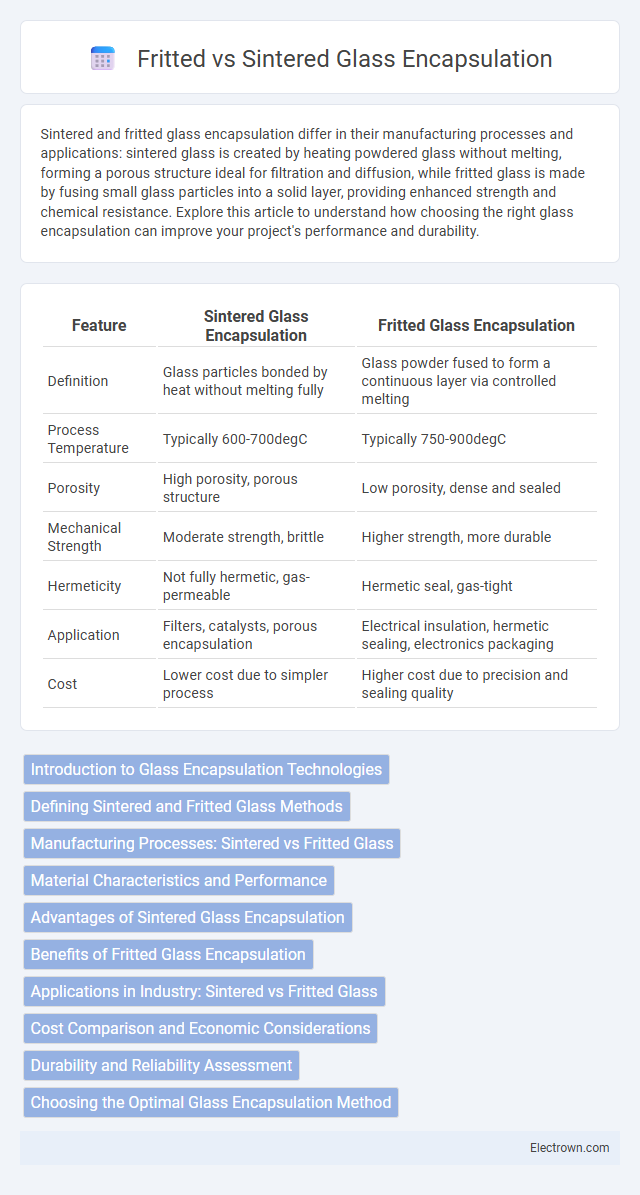

| Feature | Sintered Glass Encapsulation | Fritted Glass Encapsulation |

|---|---|---|

| Definition | Glass particles bonded by heat without melting fully | Glass powder fused to form a continuous layer via controlled melting |

| Process Temperature | Typically 600-700degC | Typically 750-900degC |

| Porosity | High porosity, porous structure | Low porosity, dense and sealed |

| Mechanical Strength | Moderate strength, brittle | Higher strength, more durable |

| Hermeticity | Not fully hermetic, gas-permeable | Hermetic seal, gas-tight |

| Application | Filters, catalysts, porous encapsulation | Electrical insulation, hermetic sealing, electronics packaging |

| Cost | Lower cost due to simpler process | Higher cost due to precision and sealing quality |

Introduction to Glass Encapsulation Technologies

Glass encapsulation technologies enhance device protection by providing robust, hermetic seals that prevent moisture and contaminants ingress. Sintered glass encapsulation involves fusing glass particles through controlled heat without melting, creating a porous yet strong barrier ideal for sensor packaging. Fritted glass encapsulation uses powdered glass melted into a glassy matrix, offering superior mechanical stability and hermeticity for electronic and optical applications.

Defining Sintered and Fritted Glass Methods

Sintered glass encapsulation involves fusing fine glass particles through heat without melting them completely, creating a porous matrix ideal for filtration and protective coatings. Fritted glass encapsulation, by contrast, uses glass frit--small granules or powder--melted and fused onto surfaces to form a continuous, robust glass layer. Your choice between sintered and fritted glass methods depends on the desired porosity and strength of the encapsulation in your application.

Manufacturing Processes: Sintered vs Fritted Glass

Sintered glass encapsulation involves heating glass particles below their melting point until they fuse, creating a porous structure that provides strength and durability without full liquefaction. Fritted glass encapsulation uses a powdered glass frit that melts and fuses onto surfaces during firing, forming a dense, smooth, and often hermetic coating or seal. Your choice between sintered and fritted glass depends on factors like desired porosity, thermal stability, and the specific application environment.

Material Characteristics and Performance

Sintered glass encapsulation offers high porosity and mechanical strength due to its particle-fused microstructure, enhancing filtration efficiency and durability in high-temperature applications. Fritted glass encapsulation provides a more uniform pore size distribution with a smoother surface, resulting in excellent chemical resistance and minimal surface contamination, ideal for sensitive analytical processes. Your choice depends on required filtration precision and environmental resistance, with sintered glass excelling in rugged conditions and fritted glass optimized for clean, consistent separations.

Advantages of Sintered Glass Encapsulation

Sintered glass encapsulation offers superior mechanical strength and enhanced chemical resistance compared to fritted glass, ensuring long-lasting durability in harsh environments. Its porous structure provides excellent thermal stability and efficient gas permeability, making it ideal for filtration and sensing applications. You benefit from improved performance and reliability in demanding industrial and laboratory processes.

Benefits of Fritted Glass Encapsulation

Fritted glass encapsulation offers superior durability and chemical resistance compared to sintered glass, making it ideal for long-term use in harsh environments. Its smooth, non-porous surface minimizes contamination risk and facilitates easier cleaning, which enhances sensor accuracy and reliability. You benefit from improved performance and reduced maintenance costs when choosing fritted glass encapsulation for sensitive analytical applications.

Applications in Industry: Sintered vs Fritted Glass

Sintered glass encapsulation offers exceptional mechanical strength and thermal stability, making it ideal for industrial applications such as filtration in chemical processing, gas diffusion, and high-temperature environments. Fritted glass, with its fine porous structure, excels in precision gas sparging, liquid dispersion, and catalytic support in pharmaceutical and environmental monitoring industries. Both materials provide chemical resistance and durability, but choice depends on specific industry requirements regarding pore size, flow control, and operational conditions.

Cost Comparison and Economic Considerations

Sintered glass encapsulation typically incurs higher initial costs due to complex manufacturing processes involving high-temperature powder fusion, yet offers superior durability and long-term performance, reducing maintenance expenses. Fritted glass encapsulation provides a more cost-effective alternative with lower production expenses, though it may require more frequent replacements, impacting overall lifecycle costs. Evaluating total cost of ownership involves balancing upfront investment against potential savings in reliability and service intervals.

Durability and Reliability Assessment

Sintered glass encapsulation demonstrates superior durability due to its microporous structure, which enhances mechanical strength and thermal stability over a wide range of operating conditions. Fritted glass encapsulation provides reliable hermetic sealing with excellent chemical resistance but may exhibit lower mechanical robustness under extreme environmental stress. Comparative assessments reveal sintered glass offers enhanced long-term reliability, particularly in applications requiring high thermal shock resistance and structural integrity.

Choosing the Optimal Glass Encapsulation Method

Sintered glass encapsulation offers superior mechanical strength and chemical resistance, making it ideal for high-pressure and high-temperature environments, whereas fritted glass provides a more cost-effective solution with good thermal stability and ease of manufacturing. Selecting the optimal glass encapsulation method depends on application-specific requirements such as thermal expansion properties, chemical compatibility, and long-term durability. Evaluating factors like operating conditions and budget constraints ensures the choice aligns with performance demands and cost efficiency.

Sintered vs Fritted glass encapsulation Infographic

electrown.com

electrown.com