Edge couplers provide high efficiency and low insertion loss by directly aligning an optical fiber to the edge of a photonic chip, making them ideal for applications requiring robust, stable connections. Grating couplers, on the other hand, offer easier wafer-level testing and flexible vertical fiber coupling but often suffer from higher loss and narrower bandwidth; explore the rest of the article to understand which solution best fits your optical communication needs.

Table of Comparison

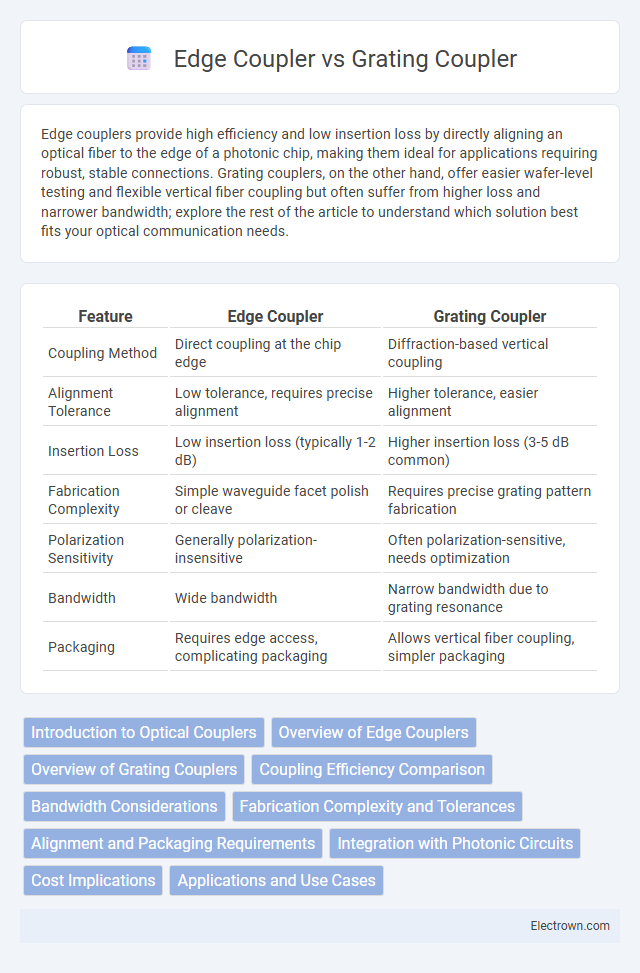

| Feature | Edge Coupler | Grating Coupler |

|---|---|---|

| Coupling Method | Direct coupling at the chip edge | Diffraction-based vertical coupling |

| Alignment Tolerance | Low tolerance, requires precise alignment | Higher tolerance, easier alignment |

| Insertion Loss | Low insertion loss (typically 1-2 dB) | Higher insertion loss (3-5 dB common) |

| Fabrication Complexity | Simple waveguide facet polish or cleave | Requires precise grating pattern fabrication |

| Polarization Sensitivity | Generally polarization-insensitive | Often polarization-sensitive, needs optimization |

| Bandwidth | Wide bandwidth | Narrow bandwidth due to grating resonance |

| Packaging | Requires edge access, complicating packaging | Allows vertical fiber coupling, simpler packaging |

Introduction to Optical Couplers

Optical couplers serve as critical components for efficient light transmission between optical fibers and photonic integrated circuits. Edge couplers achieve low-loss coupling by directly aligning the fiber end-face with the waveguide facet, providing broadband performance and compatibility with various waveguide geometries. Grating couplers use diffractive elements etched into the waveguide surface to couple light vertically, enabling wafer-scale testing and simplified packaging despite typically higher insertion loss and narrower spectral bandwidth compared to edge couplers.

Overview of Edge Couplers

Edge couplers enable efficient light coupling between optical fibers and planar waveguides by aligning the fiber directly to the chip's edge, minimizing insertion loss and back-reflection. Their high coupling efficiency and broadband performance make them ideal for high-speed photonic integrated circuits where low-loss interconnection is critical. You should consider edge couplers when precise alignment and strong mode matching to the waveguide mode are required for optimal signal transmission.

Overview of Grating Couplers

Grating couplers efficiently couple light between optical fibers and photonic integrated circuits by diffracting light through a periodic structure etched onto the waveguide surface. They offer ease of alignment and fabrication compared to edge couplers, making them ideal for wafer-scale testing and packaging. Your choice between grating couplers and edge couplers depends on factors like coupling efficiency, bandwidth, and fabrication complexity.

Coupling Efficiency Comparison

Edge couplers typically offer higher coupling efficiency, often exceeding 90%, by directly aligning the fiber to the waveguide facet, minimizing insertion loss. Grating couplers present lower coupling efficiencies, generally around 60-70%, due to diffraction losses and limited coupling bandwidth. Your choice depends on the specific integration requirements, balancing ease of alignment against maximum power transfer efficiency.

Bandwidth Considerations

Edge couplers typically offer broader bandwidth performance due to their direct waveguide-to-fiber coupling, minimizing wavelength-dependent losses. Grating couplers, while compact and easy to integrate on-chip, often exhibit narrower bandwidths because their diffraction efficiency varies with wavelength. Selecting the right coupler for your photonic system depends on balancing bandwidth needs with integration constraints.

Fabrication Complexity and Tolerances

Edge couplers require precise cleaving and polished facets, resulting in higher fabrication complexity and stringent alignment tolerances to ensure efficient light coupling. Grating couplers offer more relaxed fabrication tolerances by enabling surface coupling with lithographically defined gratings, simplifying integration but often introducing sensitivity to wavelength and polarization variations. Your choice between these technologies should consider the trade-off between fabrication complexity and the desired coupling performance in the photonic integrated circuit.

Alignment and Packaging Requirements

Edge couplers demand precise horizontal alignment with optical fibers due to their sensitivity to lateral and vertical misalignments, often requiring complex packaging solutions with strict tolerances. Grating couplers offer easier vertical alignment and simplified packaging by coupling light through the chip surface, but they typically suffer from lower coupling efficiency and narrower operational bandwidth. The choice between these couplers depends on balancing alignment tolerance with packaging complexity and overall system performance requirements.

Integration with Photonic Circuits

Edge couplers provide efficient direct coupling between optical fibers and photonic circuits by aligning the fiber core precisely with the waveguide facet, enabling low-loss integration suitable for high-density photonic chips. Grating couplers facilitate surface-normal light coupling through diffractive structures etched on the chip surface, offering simplified alignment and wafer-level testing but typically exhibiting higher insertion loss compared to edge couplers. Integration choice depends on fabrication complexity, system design, and required coupling efficiency, with edge couplers favored for high-performance photonic integrated circuits and grating couplers preferred for prototyping and flexible packaging.

Cost Implications

Edge couplers generally incur lower initial manufacturing costs due to simpler fabrication processes and compatibility with standard packaging techniques. Grating couplers, while offering better alignment tolerance and wafer-level testing advantages, often result in higher production expenses due to complex lithography and etching steps. Your choice should consider volume requirements and alignment precision against these cost implications to optimize overall project budgets.

Applications and Use Cases

Edge couplers excel in high-performance photonic circuits where minimal insertion loss and wide bandwidth are critical, commonly used in datacenter interconnects and on-chip optical communication. Grating couplers offer flexible wafer-scale testing and simplified vertical coupling, making them ideal for rapid prototyping and applications requiring easy alignment, such as silicon photonics sensors and integrated optical transceivers. Your choice depends on the specific requirements of integration density, alignment tolerance, and manufacturing throughput.

Edge coupler vs Grating coupler Infographic

electrown.com

electrown.com