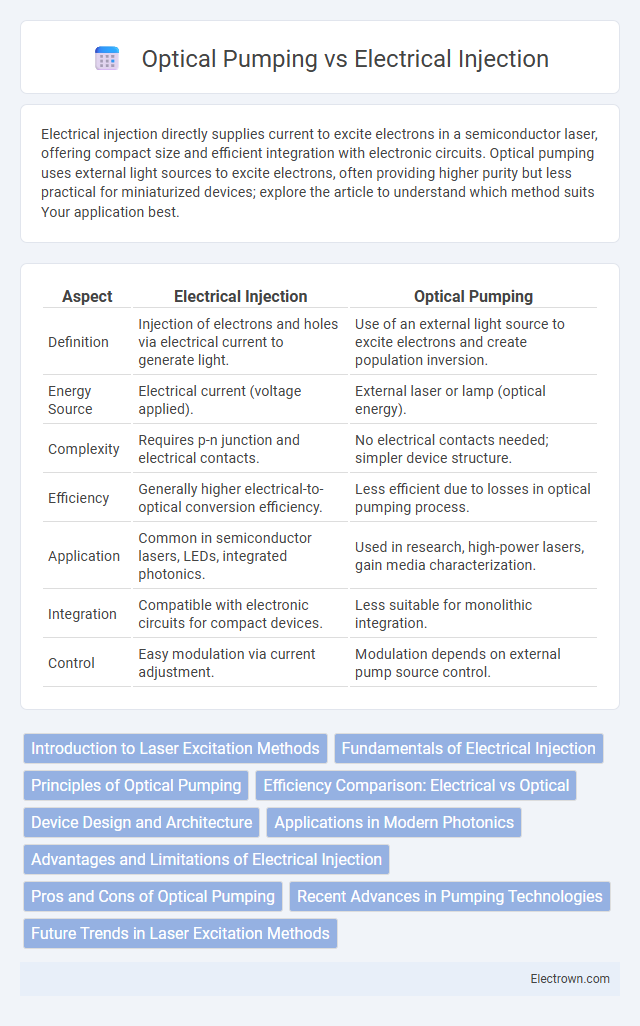

Electrical injection directly supplies current to excite electrons in a semiconductor laser, offering compact size and efficient integration with electronic circuits. Optical pumping uses external light sources to excite electrons, often providing higher purity but less practical for miniaturized devices; explore the article to understand which method suits Your application best.

Table of Comparison

| Aspect | Electrical Injection | Optical Pumping |

|---|---|---|

| Definition | Injection of electrons and holes via electrical current to generate light. | Use of an external light source to excite electrons and create population inversion. |

| Energy Source | Electrical current (voltage applied). | External laser or lamp (optical energy). |

| Complexity | Requires p-n junction and electrical contacts. | No electrical contacts needed; simpler device structure. |

| Efficiency | Generally higher electrical-to-optical conversion efficiency. | Less efficient due to losses in optical pumping process. |

| Application | Common in semiconductor lasers, LEDs, integrated photonics. | Used in research, high-power lasers, gain media characterization. |

| Integration | Compatible with electronic circuits for compact devices. | Less suitable for monolithic integration. |

| Control | Easy modulation via current adjustment. | Modulation depends on external pump source control. |

Introduction to Laser Excitation Methods

Electrical injection and optical pumping are two primary laser excitation methods used to achieve population inversion in laser mediums. Electrical injection directly supplies carriers through current flow in semiconductor lasers, enabling compact, efficient, and easily integrated devices. Optical pumping utilizes an external light source to excite the laser medium, offering precise control over excitation but requiring more complex setups, which may affect your choice depending on the application's scale and environment.

Fundamentals of Electrical Injection

Electrical injection involves directly introducing charge carriers, electrons, and holes, into a semiconductor's active region via electrical contacts, enabling recombination and photon emission. This process is fundamental to devices such as laser diodes and light-emitting diodes (LEDs), where current injection controls the optical output efficiency and wavelength. Electrical injection ensures compact, electrically driven operation essential for integrated photonic circuits and optoelectronic applications.

Principles of Optical Pumping

Optical pumping relies on using light to excite electrons from lower to higher energy states within a semiconductor material, creating a population inversion essential for laser action. This process involves directing an external light source, such as a laser diode or flashlamp, to provide photons that are absorbed by the gain medium, increasing electron energy levels without direct electrical input. Your understanding of optical pumping highlights its advantage in generating coherent light without the need for electrical contacts, making it ideal for certain laser applications.

Efficiency Comparison: Electrical vs Optical

Electrical injection typically offers higher energy efficiency than optical pumping due to direct carrier injection into the active region, minimizing losses associated with light absorption and conversion. Optical pumping requires an external light source, which introduces additional energy overhead and reduces overall system efficiency. Optimizing your device with electrical injection can significantly enhance performance by reducing power consumption and improving photon generation efficiency.

Device Design and Architecture

Electrical injection devices utilize integrated electrodes and semiconductor junctions for direct carrier injection, enabling compact and scalable architectures ideal for on-chip applications. Optical pumping relies on external light sources to excite carriers, which often requires complex alignment and limits miniaturization compared to electrically injected devices. Your choice between these methods depends on the desired device size, integration level, and application-specific performance requirements.

Applications in Modern Photonics

Electrical injection is the primary method for powering semiconductor lasers in integrated photonic circuits, enabling efficient on-chip light sources for optical communication and data transmission. Optical pumping is widely used in high-power solid-state and fiber lasers where precise control of the pump wavelength and intensity enhances output stability, crucial for medical and industrial applications. Both techniques play key roles in photonic devices, with electrical injection dominating compact, low-power applications and optical pumping favored in scalable, high-performance laser systems.

Advantages and Limitations of Electrical Injection

Electrical injection provides direct carrier injection into semiconductor laser diodes, enabling compact, energy-efficient devices with straightforward integration into electronic circuits. This technique offers precise control over current density and facilitates continuous-wave operation at room temperature, critical for practical applications such as telecommunications and data storage. Limitations include challenges in heat dissipation, potential efficiency droop at high current densities, and complex fabrication processes compared to optical pumping methods.

Pros and Cons of Optical Pumping

Optical pumping offers high spatial and temporal coherence, making it ideal for applications requiring precise control over light properties, such as in advanced spectroscopy and quantum computing. It allows for selective excitation of specific energy states without electrical contacts, reducing electrical noise and simplifying device architecture. However, optical pumping requires complex external light sources and precise alignment, which can increase system cost and limit integration into compact, electrically-driven devices.

Recent Advances in Pumping Technologies

Recent advances in electrical injection pumping have improved efficiency and integration in semiconductor laser devices, leveraging novel materials like quantum dots and nanostructures to enhance performance. Optical pumping technologies have seen breakthroughs with high-power diode lasers and ultrafast pulsed sources, enabling precise control over gain media and facilitating applications in spectroscopy and communications. Your choice between electrical injection and optical pumping depends on specific device requirements, including power efficiency, wavelength stability, and fabrication complexity.

Future Trends in Laser Excitation Methods

Future trends in laser excitation methods emphasize the integration of electrical injection techniques to achieve more compact, energy-efficient, and scalable devices for photonic applications. Optical pumping continues to be valuable for high-power and tunable lasers, but advancements in semiconductor materials and nanostructures are driving electrical injection toward widespread use in practical, on-chip laser sources. Your choice of excitation method will increasingly depend on the specific balance between efficiency, device size, and application demands in emerging technologies like integrated photonics and quantum computing.

Electrical injection vs Optical pumping Infographic

electrown.com

electrown.com