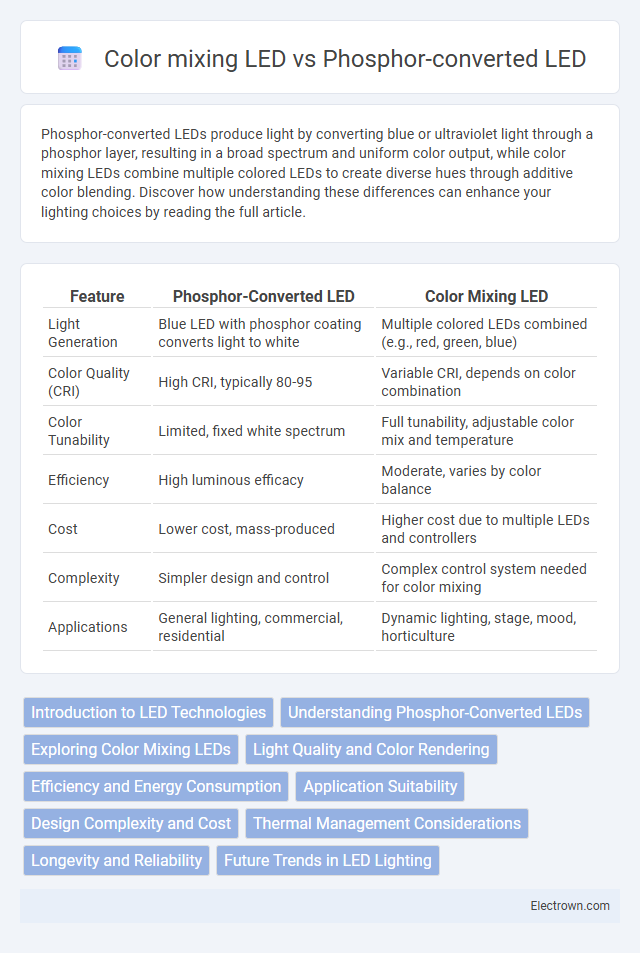

Phosphor-converted LEDs produce light by converting blue or ultraviolet light through a phosphor layer, resulting in a broad spectrum and uniform color output, while color mixing LEDs combine multiple colored LEDs to create diverse hues through additive color blending. Discover how understanding these differences can enhance your lighting choices by reading the full article.

Table of Comparison

| Feature | Phosphor-Converted LED | Color Mixing LED |

|---|---|---|

| Light Generation | Blue LED with phosphor coating converts light to white | Multiple colored LEDs combined (e.g., red, green, blue) |

| Color Quality (CRI) | High CRI, typically 80-95 | Variable CRI, depends on color combination |

| Color Tunability | Limited, fixed white spectrum | Full tunability, adjustable color mix and temperature |

| Efficiency | High luminous efficacy | Moderate, varies by color balance |

| Cost | Lower cost, mass-produced | Higher cost due to multiple LEDs and controllers |

| Complexity | Simpler design and control | Complex control system needed for color mixing |

| Applications | General lighting, commercial, residential | Dynamic lighting, stage, mood, horticulture |

Introduction to LED Technologies

Phosphor-converted LEDs utilize a blue or UV LED chip combined with a phosphor coating to produce white light by converting the emitted wavelength, enabling high color rendering index and energy efficiency. Color mixing LEDs employ separate red, green, and blue LED chips that blend their light output to create a wide spectrum of colors, allowing precise color tuning and dynamic lighting effects. Both technologies offer distinct advantages in applications ranging from general lighting to display and entertainment systems, driven by differing mechanisms in light generation and color production.

Understanding Phosphor-Converted LEDs

Phosphor-converted LEDs (pc-LEDs) use a blue or ultraviolet LED chip coated with a phosphor material that absorbs the primary light and re-emits it at different wavelengths to produce white light. This technology offers high color stability, energy efficiency, and simplified manufacturing compared to color mixing LEDs, which combine multiple colored LEDs to create white or various hues. Understanding the phosphor conversion process is key to optimizing color rendering index (CRI), luminous efficacy, and thermal management in lighting applications.

Exploring Color Mixing LEDs

Color mixing LEDs combine multiple LED chips of different colors, such as red, green, and blue, to produce a wide spectrum of customizable lighting hues with precise control over color rendering. Phosphor-converted LEDs rely on a blue or UV LED coated with phosphor materials to transform emitted light into a broader, often white, color spectrum, typically offering less color flexibility. Exploring color mixing LEDs reveals their advantage in dynamic lighting applications where tailored ambiance and accurate color tuning are essential for Your desired environment.

Light Quality and Color Rendering

Phosphor-converted LEDs offer high luminous efficiency with smooth, consistent white light and a broad color spectrum, resulting in superior color rendering index (CRI) values typically above 80. Color mixing LEDs combine multiple monochromatic light sources to create various hues but often suffer from uneven spectral distributions and lower CRI, which can affect the accuracy and vibrancy of colors. The uniform spectral output of phosphor-converted LEDs generally provides more natural and visually comfortable illumination compared to the variable spectral quality of color mixing LEDs.

Efficiency and Energy Consumption

Phosphor-converted LEDs typically offer higher energy efficiency by converting blue light to white light through a phosphor layer, resulting in less power consumption for the same brightness compared to color mixing LEDs. Color mixing LEDs combine red, green, and blue light to produce white light but often require more energy to achieve desired luminance, leading to higher energy consumption. Your choice between these technologies should consider phosphor-converted LEDs for better efficiency and reduced electricity costs.

Application Suitability

Phosphor-converted LEDs excel in applications requiring consistent white light with high color rendering for indoor and commercial lighting, making them ideal for office, retail, and residential environments. Color mixing LEDs offer precise control of RGB light, enabling dynamic color effects suitable for stage lighting, architectural installations, and entertainment venues. Your choice depends on whether you need stable, high-quality white illumination or versatile, customizable color outputs for specialized lighting purposes.

Design Complexity and Cost

Phosphor-converted LEDs feature simpler design architecture by using a blue LED chip coated with a phosphor layer to produce white light, resulting in lower manufacturing costs and streamlined assembly. Color mixing LEDs rely on multiple monochromatic LED chips combined within a single fixture, increasing design complexity, calibration requirements, and production expenses. Your choice depends on whether cost efficiency or precise color control is the priority in your lighting application.

Thermal Management Considerations

Phosphor-converted LEDs generate heat concentrated around the phosphor layer, requiring efficient thermal dissipation to maintain luminous efficacy and color stability. Color mixing LEDs distribute heat more evenly across multiple LED chips, potentially simplifying thermal management but necessitating careful design to prevent thermal crosstalk. Effective heat sinks and active cooling solutions are critical in both technologies to avoid thermal degradation and ensure consistent performance.

Longevity and Reliability

Phosphor-converted LEDs typically offer greater longevity and reliability due to their simpler design, which reduces thermal stress and minimizes component degradation over time. In contrast, color mixing LEDs consist of multiple LED chips of different colors that can experience uneven aging and color shift, potentially shortening overall lifespan. Studies show phosphor-converted LEDs maintain consistent light output and color stability for over 50,000 hours, whereas color mixing LEDs may require more maintenance to preserve performance.

Future Trends in LED Lighting

Phosphor-converted LEDs continue evolving with improved efficiency and color rendering, making them suitable for a broad range of applications where natural light quality is crucial. Color mixing LEDs offer dynamic control over color output, enabling personalized lighting experiences and adaptive environments that cater to smart home and commercial needs. Your choice between these technologies will increasingly depend on the demand for customization and energy-saving features as the LED lighting industry advances toward more intelligent and sustainable solutions.

Phosphor-converted LED vs Color mixing LED Infographic

electrown.com

electrown.com