Direct bandgap materials enable electrons to transition between the valence and conduction bands without changing momentum, making them highly efficient for optoelectronic devices like LEDs and laser diodes. Understanding these differences can improve Your knowledge of semiconductor applications--explore the rest of the article for detailed insights.

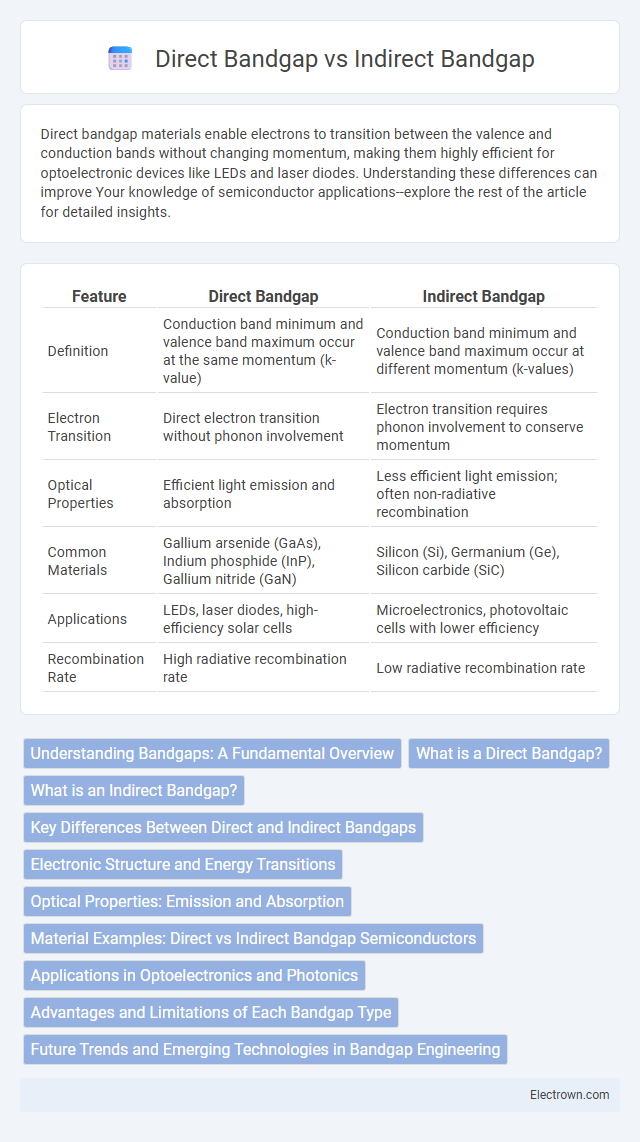

Table of Comparison

| Feature | Direct Bandgap | Indirect Bandgap |

|---|---|---|

| Definition | Conduction band minimum and valence band maximum occur at the same momentum (k-value) | Conduction band minimum and valence band maximum occur at different momentum (k-values) |

| Electron Transition | Direct electron transition without phonon involvement | Electron transition requires phonon involvement to conserve momentum |

| Optical Properties | Efficient light emission and absorption | Less efficient light emission; often non-radiative recombination |

| Common Materials | Gallium arsenide (GaAs), Indium phosphide (InP), Gallium nitride (GaN) | Silicon (Si), Germanium (Ge), Silicon carbide (SiC) |

| Applications | LEDs, laser diodes, high-efficiency solar cells | Microelectronics, photovoltaic cells with lower efficiency |

| Recombination Rate | High radiative recombination rate | Low radiative recombination rate |

Understanding Bandgaps: A Fundamental Overview

Direct bandgap semiconductors allow electrons to transition directly between the conduction band and valence band without a change in momentum, enabling efficient light emission in devices like LEDs and laser diodes. Indirect bandgap materials require a phonon to conserve momentum during electron transitions, which reduces their radiative recombination efficiency and makes them less suitable for optoelectronic applications. Understanding these bandgap types is crucial for selecting materials in semiconductor physics and designing photonic devices.

What is a Direct Bandgap?

A direct bandgap occurs when the minimum of the conduction band and the maximum of the valence band align at the same momentum value, allowing electrons to directly recombine with holes and emit photons efficiently. Materials like Gallium Arsenide (GaAs) exhibit a direct bandgap, making them ideal for optoelectronic devices such as LEDs and laser diodes. Your choice of semiconductor material impacts the efficiency of light emission based on whether it possesses a direct or indirect bandgap.

What is an Indirect Bandgap?

An indirect bandgap is a characteristic of certain semiconductors where the maximum of the valence band and the minimum of the conduction band occur at different momentum values in the Brillouin zone. This momentum mismatch requires phonon involvement for electron transitions, leading to less efficient optical emission compared to direct bandgap materials. Silicon is a prime example of an indirect bandgap semiconductor, impacting its performance in optoelectronic devices.

Key Differences Between Direct and Indirect Bandgaps

Direct bandgap semiconductors allow electrons to directly transition between the conduction band minimum and valence band maximum, enabling efficient light emission critical for optoelectronic devices like LEDs and laser diodes. Indirect bandgap materials require a phonon interaction for electron transition due to momentum mismatch, resulting in lower radiative recombination rates and less efficient light emission, commonly found in silicon. The key difference lies in the momentum conservation during electron transitions, which directly influences the material's optical properties and suitability for specific applications.

Electronic Structure and Energy Transitions

Direct bandgap materials exhibit electronic structures where the conduction band minimum and valence band maximum align at the same momentum, enabling efficient energy transitions through photon emission. In contrast, indirect bandgap materials have conduction band minima and valence band maxima at different momentum values, requiring phonon involvement for energy transitions and resulting in less efficient radiative recombination. Your choice between these materials significantly impacts optoelectronic device performance, especially in light-emitting applications.

Optical Properties: Emission and Absorption

Direct bandgap semiconductors exhibit efficient optical emission and strong absorption due to the alignment of conduction band minimum and valence band maximum at the same momentum, facilitating direct electron-hole recombination and photon interaction. Indirect bandgap materials require phonon involvement for emission and absorption processes, resulting in weaker photoluminescence and lower optical absorption efficiency. This fundamental difference makes direct bandgap materials preferable for light-emitting devices and high-performance photodetectors.

Material Examples: Direct vs Indirect Bandgap Semiconductors

Direct bandgap semiconductors such as gallium arsenide (GaAs) and indium phosphide (InP) enable efficient light emission due to the alignment of conduction band minimum and valence band maximum at the same momentum. Indirect bandgap semiconductors like silicon (Si) and germanium (Ge) require phonon assistance for electron transitions, resulting in lower optical emission efficiency. These material characteristics crucially influence their applications, with direct bandgap materials preferred for optoelectronic devices and indirect bandgap materials commonly used in microelectronics.

Applications in Optoelectronics and Photonics

Direct bandgap semiconductors, such as gallium arsenide (GaAs), are highly efficient for optoelectronic devices like LEDs and laser diodes due to their ability to emit light directly when electrons recombine with holes. Indirect bandgap materials, like silicon, have limited light emission efficiency, making them more suitable for electronic devices rather than photonics. Your choice of material directly impacts the performance and efficiency of photonic applications, especially in developing high-speed optical communication systems and photodetectors.

Advantages and Limitations of Each Bandgap Type

Direct bandgap semiconductors enable efficient light emission, making them ideal for LEDs and laser diodes due to their high radiative recombination rates. Indirect bandgap materials, such as silicon, exhibit lower light emission efficiency but excel in electronic applications like transistors and solar cells because of their superior charge carrier mobility and abundance. The limitation of direct bandgap materials lies in their complex fabrication and typically higher cost, whereas indirect bandgap semiconductors face challenges in optoelectronic efficiency but benefit from mature processing technologies and material availability.

Future Trends and Emerging Technologies in Bandgap Engineering

Future trends in bandgap engineering emphasize the development of hybrid perovskite materials with tunable direct bandgaps for enhanced optoelectronic applications, including solar cells and light-emitting diodes. Emerging technologies leverage two-dimensional materials like transition metal dichalcogenides (TMDCs) that exhibit strong direct bandgap properties at the monolayer level, enabling ultrathin and flexible photonic devices. Advanced computational methods and machine learning algorithms accelerate the discovery and optimization of semiconductors with tailored direct or indirect bandgaps to improve energy efficiency and device performance.

Direct bandgap vs Indirect bandgap Infographic

electrown.com

electrown.com