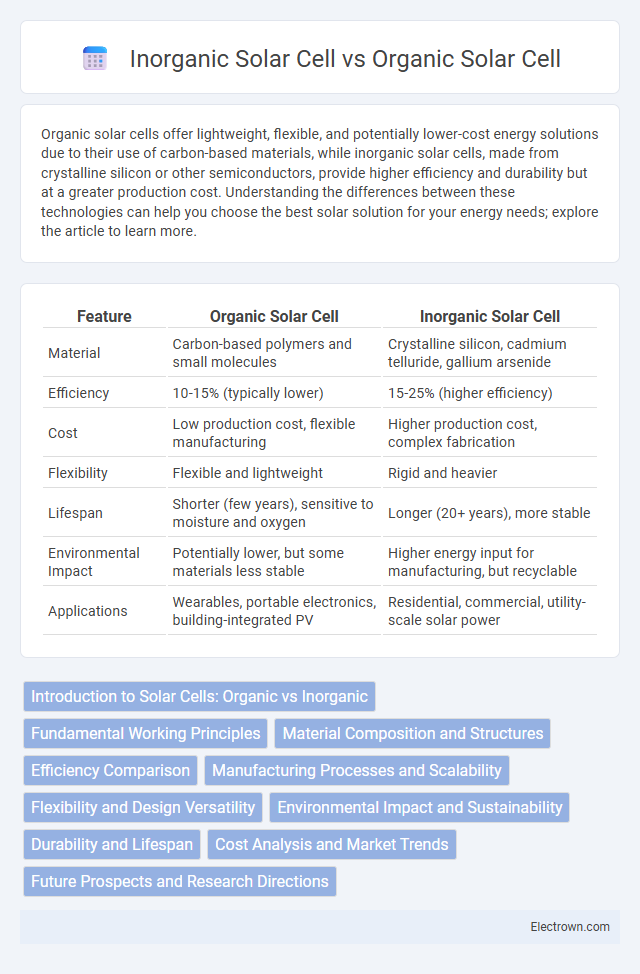

Organic solar cells offer lightweight, flexible, and potentially lower-cost energy solutions due to their use of carbon-based materials, while inorganic solar cells, made from crystalline silicon or other semiconductors, provide higher efficiency and durability but at a greater production cost. Understanding the differences between these technologies can help you choose the best solar solution for your energy needs; explore the article to learn more.

Table of Comparison

| Feature | Organic Solar Cell | Inorganic Solar Cell |

|---|---|---|

| Material | Carbon-based polymers and small molecules | Crystalline silicon, cadmium telluride, gallium arsenide |

| Efficiency | 10-15% (typically lower) | 15-25% (higher efficiency) |

| Cost | Low production cost, flexible manufacturing | Higher production cost, complex fabrication |

| Flexibility | Flexible and lightweight | Rigid and heavier |

| Lifespan | Shorter (few years), sensitive to moisture and oxygen | Longer (20+ years), more stable |

| Environmental Impact | Potentially lower, but some materials less stable | Higher energy input for manufacturing, but recyclable |

| Applications | Wearables, portable electronics, building-integrated PV | Residential, commercial, utility-scale solar power |

Introduction to Solar Cells: Organic vs Inorganic

Organic solar cells use carbon-based materials such as polymers and small molecules to convert sunlight into electricity, offering flexibility and lightweight advantages. Inorganic solar cells, primarily composed of silicon and other crystalline materials, provide higher efficiency and stability with a well-established manufacturing process. Both technologies play crucial roles in photovoltaics, with organic cells excelling in versatility and cost-effectiveness, while inorganic cells dominate in performance and commercial applications.

Fundamental Working Principles

Organic solar cells operate based on the photoactive polymers or small molecules that absorb sunlight and generate excitons, which then dissociate into free charge carriers at donor-acceptor interfaces. In contrast, inorganic solar cells, typically made from crystalline silicon or other semiconductors, rely on the p-n junction to separate photogenerated electron-hole pairs and drive current through an external circuit. The difference in exciton diffusion lengths and charge transport mechanisms fundamentally distinguishes organic solar cells' efficiency and material flexibility from the higher charge mobility and stability observed in inorganic solar cells.

Material Composition and Structures

Organic solar cells utilize carbon-based polymers or small molecules with flexible, lightweight structures, whereas inorganic solar cells primarily consist of crystalline silicon or thin-film materials like cadmium telluride and copper indium gallium selenide, known for their rigid, robust architecture. The layered design of organic cells allows for tunable absorption properties and potential for low-cost, large-area fabrication, while inorganic cells exhibit higher efficiency and long-term stability due to their well-established semiconductor properties. Understanding the distinct material composition and structural differences helps optimize Your solar technology choice for specific applications and performance goals.

Efficiency Comparison

Organic solar cells typically exhibit lower power conversion efficiencies, ranging from 10% to 15%, compared to inorganic solar cells like silicon-based panels, which achieve efficiencies exceeding 20% and reaching up to 26% in laboratory settings. The efficiency gap arises due to the intrinsic material properties, with inorganic cells benefiting from superior charge carrier mobility and longer exciton diffusion lengths. Innovations in organic photovoltaic materials and device architecture continue to narrow this efficiency disparity, but inorganic cells remain the benchmark for high-performance solar energy conversion.

Manufacturing Processes and Scalability

Organic solar cells utilize solution-based processes like spin coating and printing, enabling low-cost, flexible, and large-area manufacturing with potential for roll-to-roll production. Inorganic solar cells, typically based on silicon wafers, require high-temperature, vacuum-based fabrication techniques such as chemical vapor deposition, resulting in higher production costs and limited scalability. The scalability advantage of organic cells is counterbalanced by their lower efficiency and stability compared to the more mature, high-efficiency inorganic solar technologies.

Flexibility and Design Versatility

Organic solar cells offer superior flexibility and design versatility due to their lightweight, thin-film structure, enabling integration into curved surfaces and wearable devices. Inorganic solar cells, although typically more rigid and brittle, provide higher efficiency but lack the adaptability for innovative shapes and flexible applications. Your choice between these technologies depends on whether design flexibility or power output is the primary priority for your project.

Environmental Impact and Sustainability

Organic solar cells offer a lower environmental impact due to their use of non-toxic, abundant materials and energy-efficient manufacturing processes, which reduce carbon emissions and waste. Inorganic solar cells, typically made from silicon or rare metals, involve energy-intensive production and generate more hazardous waste, posing sustainability challenges. Your choice between these technologies can influence long-term ecological footprints and alignment with green energy goals.

Durability and Lifespan

Organic solar cells typically exhibit shorter durability and lifespans, often ranging from 1 to 5 years due to sensitivity to environmental factors like moisture, oxygen, and UV light. In contrast, inorganic solar cells, such as silicon-based panels, offer significantly longer lifespans, commonly exceeding 25 years, with robust performance stability under harsh weather conditions. Advanced encapsulation techniques for organic cells are improving their longevity but have yet to match the proven durability of inorganic counterparts.

Cost Analysis and Market Trends

Organic solar cells offer lower production costs due to inexpensive materials and flexible manufacturing processes, making them attractive for affordable, lightweight applications. Inorganic solar cells, particularly silicon-based, dominate the market with higher efficiency and stability, but entail greater manufacturing expenses and complex supply chains. Your choice depends on balancing budget constraints with performance needs, as market trends show growing interest in organic cells for niche uses and ongoing investment in inorganic technology for mass-scale energy solutions.

Future Prospects and Research Directions

Organic solar cells show promising future prospects due to their flexibility, lightweight design, and potential for low-cost, large-area production, making them ideal for integration into wearable electronics and building materials. Research is focused on improving their power conversion efficiency, stability, and lifespan through advanced polymer synthesis, interface engineering, and tandem cell architectures. Your best option for high efficiency and durability currently remains inorganic solar cells, but ongoing hybrid approaches combining organic and inorganic materials may unlock new performance thresholds.

Organic solar cell vs Inorganic solar cell Infographic

electrown.com

electrown.com