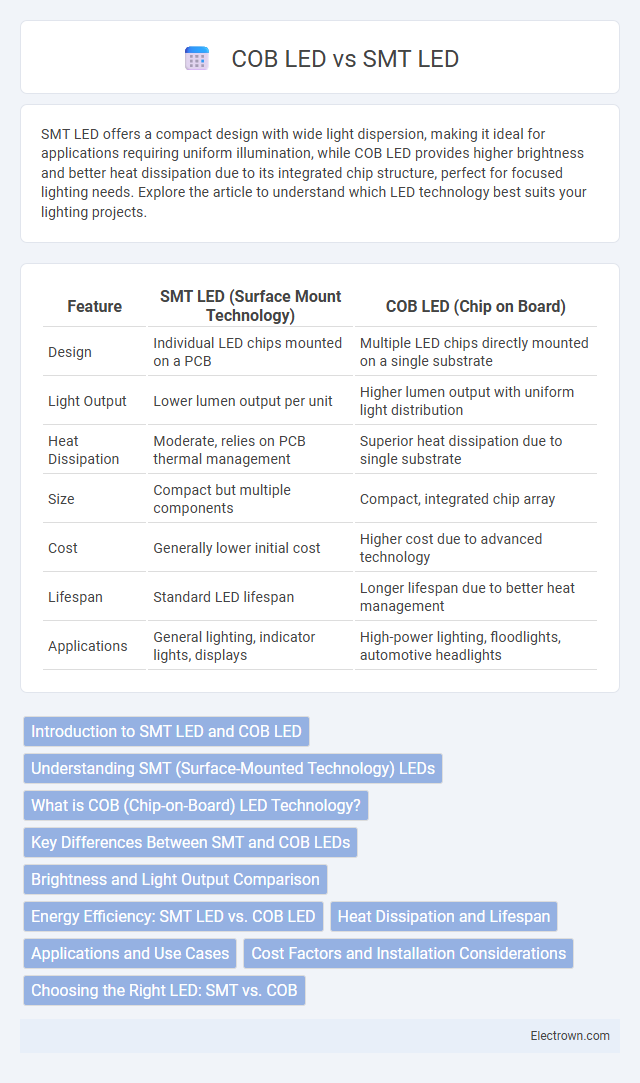

SMT LED offers a compact design with wide light dispersion, making it ideal for applications requiring uniform illumination, while COB LED provides higher brightness and better heat dissipation due to its integrated chip structure, perfect for focused lighting needs. Explore the article to understand which LED technology best suits your lighting projects.

Table of Comparison

| Feature | SMT LED (Surface Mount Technology) | COB LED (Chip on Board) |

|---|---|---|

| Design | Individual LED chips mounted on a PCB | Multiple LED chips directly mounted on a single substrate |

| Light Output | Lower lumen output per unit | Higher lumen output with uniform light distribution |

| Heat Dissipation | Moderate, relies on PCB thermal management | Superior heat dissipation due to single substrate |

| Size | Compact but multiple components | Compact, integrated chip array |

| Cost | Generally lower initial cost | Higher cost due to advanced technology |

| Lifespan | Standard LED lifespan | Longer lifespan due to better heat management |

| Applications | General lighting, indicator lights, displays | High-power lighting, floodlights, automotive headlights |

Introduction to SMT LED and COB LED

SMT LED (Surface-Mounted Technology Light Emitting Diode) features individual diodes mounted directly onto a circuit board, offering versatile applications with compact size and efficient heat dissipation. COB LED (Chip on Board Light Emitting Diode) integrates multiple LED chips into a single module, providing uniform light output and higher lumen density ideal for high-intensity lighting. Understanding these technologies helps you select the best LED solution based on brightness, energy efficiency, and design requirements.

Understanding SMT (Surface-Mounted Technology) LEDs

SMT LEDs feature compact, chip-like components mounted directly onto printed circuit boards, enabling efficient heat dissipation and flexible design integration. Compared to COB (Chip on Board) LEDs, SMT LEDs offer individual control over each diode, resulting in customizable brightness and color effects. Their small size and ease of installation make SMT LEDs ideal for applications requiring precise lighting arrangements and high versatility.

What is COB (Chip-on-Board) LED Technology?

COB (Chip-on-Board) LED technology involves mounting multiple LED chips directly onto a single substrate, creating a uniform and intense light source with improved thermal management. Unlike SMT (Surface-Mounted Technology) LEDs, which consist of individual diodes placed separately, COB LEDs provide higher lumen density and better energy efficiency. Your lighting applications benefit from COB LEDs through enhanced brightness, reduced heat generation, and a compact design ideal for focused illumination.

Key Differences Between SMT and COB LEDs

SMT LEDs feature multiple individual light-emitting diodes mounted separately on a circuit board, offering flexible design and easy heat dissipation, whereas COB LEDs consist of a single chip with numerous LED chips packed tightly, providing higher light intensity and uniform illumination. The efficiency of COB LEDs results in better thermal management and longer lifespan compared to SMT LEDs, which may suffer from uneven light distribution. Understanding these key differences helps you choose the right LED technology for applications requiring either versatility or concentrated brightness.

Brightness and Light Output Comparison

COB LED technology delivers higher brightness and superior light output compared to SMT LED due to its larger, single-chip design that allows for better heat dissipation and uniform illumination. SMT LEDs, composed of multiple small chips, typically produce less intense and more scattered light with lower lumen output per unit. Your choice depends on whether you prioritize intense, focused brightness from COB LEDs or the flexibility and cost-effectiveness of SMT LEDs.

Energy Efficiency: SMT LED vs. COB LED

SMT LEDs offer higher energy efficiency due to their compact size and advanced semiconductor technology, enabling lower power consumption and less heat generation. COB LEDs, while effective in delivering intense brightness, generally consume more energy as they use larger chip arrays that produce more heat and require additional cooling. Choosing SMT LED technology results in better performance per watt, making it ideal for sustainable lighting solutions with reduced energy costs.

Heat Dissipation and Lifespan

SMT LED modules typically offer better heat dissipation due to their separated diodes on a larger substrate, reducing thermal buildup and enhancing durability. COB LED technology, while compact and bright, concentrates heat in a smaller area, which can lead to faster thermal degradation if not properly managed. Optimizing your lighting system with effective heat sinks will extend the lifespan of either SMT or COB LEDs, ensuring longer-lasting performance.

Applications and Use Cases

SMT LEDs excel in applications requiring surface-mounted components with high versatility, such as in electronic displays, indicator lights, and general lighting where compact size and efficient heat dissipation are crucial. COB LEDs are ideal for high-intensity lighting needs, including street lights, automotive headlights, and stage lighting, offering superior brightness and uniform light distribution due to their integrated chip design. Your choice between SMT and COB LEDs depends on the specific lighting requirements of your project, balancing factors like brightness, heat management, and spatial constraints.

Cost Factors and Installation Considerations

SMT LED technology generally offers lower manufacturing costs due to its simpler assembly and use of smaller, discrete components compared to COB LED, which requires a more complex chip-on-board process. Installation of SMT LEDs is typically easier and more flexible because they can be mounted on various substrates and adjusted for different lighting applications, whereas COB LEDs demand precise thermal management and robust heat sinks to maintain performance and longevity. Cost factors for COB LEDs are higher but justified by superior lumen output and uniform light distribution ideal for high-intensity applications.

Choosing the Right LED: SMT vs. COB

SMT LEDs offer versatility with individually packaged diodes suitable for applications requiring precise light distribution and easier maintenance. COB LEDs provide higher lumen density and better thermal management, making them ideal for high-intensity lighting and uniform illumination. Selecting between SMT and COB depends on factors like brightness needs, heat dissipation, and the specific lighting application environment.

SMT LED vs COB LED Infographic

electrown.com

electrown.com