Synchronous rectification uses MOSFETs to reduce voltage drop and improve efficiency compared to traditional diode rectification, which relies on semiconductor diodes causing higher power losses. Explore the rest of the article to understand how your power conversion choices impact performance and efficiency.

Table of Comparison

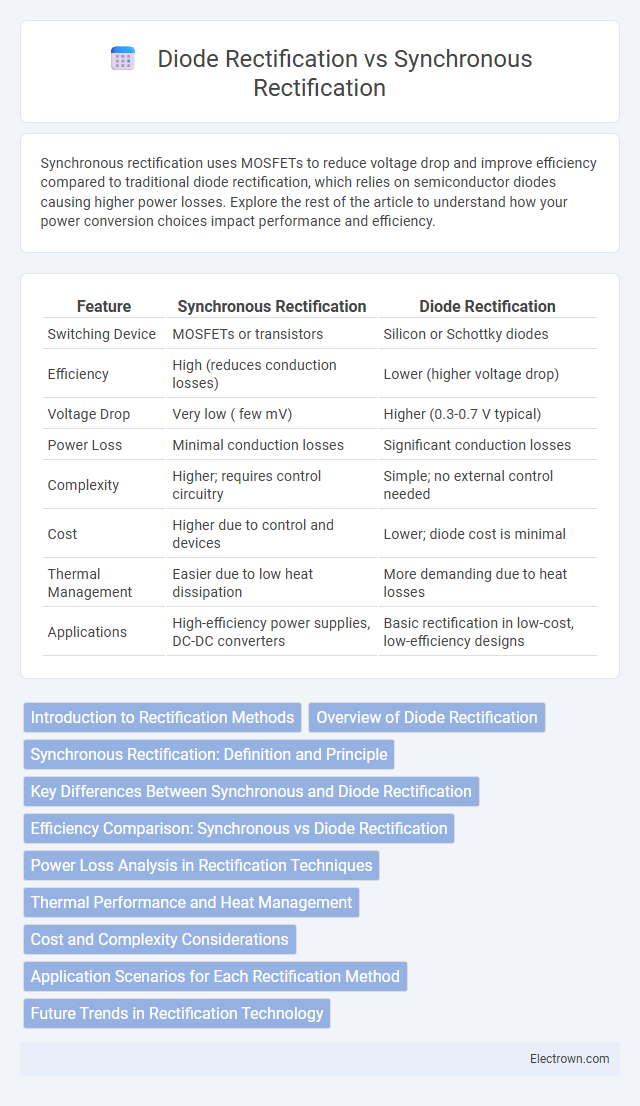

| Feature | Synchronous Rectification | Diode Rectification |

|---|---|---|

| Switching Device | MOSFETs or transistors | Silicon or Schottky diodes |

| Efficiency | High (reduces conduction losses) | Lower (higher voltage drop) |

| Voltage Drop | Very low ( few mV) | Higher (0.3-0.7 V typical) |

| Power Loss | Minimal conduction losses | Significant conduction losses |

| Complexity | Higher; requires control circuitry | Simple; no external control needed |

| Cost | Higher due to control and devices | Lower; diode cost is minimal |

| Thermal Management | Easier due to low heat dissipation | More demanding due to heat losses |

| Applications | High-efficiency power supplies, DC-DC converters | Basic rectification in low-cost, low-efficiency designs |

Introduction to Rectification Methods

Synchronous rectification utilizes MOSFETs controlled by a switching circuit to reduce conduction losses compared to traditional diode rectification, which relies on semiconductor diodes for current flow direction control. This method significantly improves efficiency, especially in low-voltage, high-current applications, by minimizing forward voltage drop. In contrast, diode rectification is simpler and more cost-effective but suffers higher power dissipation due to the inherent voltage drop across diodes.

Overview of Diode Rectification

Diode rectification uses semiconductor diodes to convert alternating current (AC) to direct current (DC) by allowing current to flow in only one direction, creating a simple and reliable conversion method. This approach, while widely used, typically results in higher power losses due to the forward voltage drop across the diode, usually around 0.7V for silicon diodes. Understanding these losses is essential for evaluating the efficiency of power supplies and comparing diode rectification with synchronous rectification technologies.

Synchronous Rectification: Definition and Principle

Synchronous rectification is a power conversion technique that uses actively controlled MOSFETs instead of conventional diodes to achieve lower conduction losses during the rectification process. The principle relies on switching the MOSFETs in synchronization with the input AC signal to allow current flow with minimal voltage drop, significantly improving efficiency in DC-DC converters and power supplies. This method reduces heat dissipation and enhances overall system performance, especially in low-voltage, high-current applications.

Key Differences Between Synchronous and Diode Rectification

Synchronous rectification uses MOSFETs instead of diodes to reduce voltage drop and improve efficiency, especially at low output voltages and high currents. Diode rectification relies on the inherent forward voltage drop of diodes, which causes higher power losses and heat dissipation. Key differences include the lower conduction losses and better thermal performance of synchronous rectifiers compared to the simplicity and robustness of diode rectifiers.

Efficiency Comparison: Synchronous vs Diode Rectification

Synchronous rectification offers significantly higher efficiency than traditional diode rectification by replacing diodes with low-resistance MOSFETs, which reduces conduction losses especially at low voltage and high current. This improvement can boost power conversion efficiency by up to 10% or more, making synchronous rectifiers ideal for applications requiring minimal energy dissipation. By choosing synchronous rectification, you optimize your power supply design for maximum energy savings and thermal performance.

Power Loss Analysis in Rectification Techniques

Synchronous rectification significantly reduces power loss compared to diode rectification by replacing diodes with low-resistance MOSFETs that have lower forward voltage drop, leading to higher efficiency especially in low voltage, high current applications. Diode rectifiers exhibit increased conduction losses due to their fixed forward voltage drop (typically 0.7V for silicon diodes), resulting in greater power dissipation and heat generation. This reduction in conduction loss with synchronous rectification decreases overall power loss, improves thermal performance, and enables more compact power supply designs.

Thermal Performance and Heat Management

Synchronous rectification offers superior thermal performance compared to diode rectification by utilizing low-resistance MOSFETs instead of diodes, significantly reducing conduction losses and heat generation. This enhanced efficiency minimizes the need for extensive heat sinks and improves overall system reliability in high-current applications. Proper heat management in synchronous rectifiers extends device lifespan and enables compact designs with better thermal dissipation characteristics.

Cost and Complexity Considerations

Synchronous rectification typically incurs higher upfront costs and increased circuit complexity due to the need for MOSFETs and driver circuitry, compared to the simpler, more cost-effective diode rectification using standard diodes. Your power supply design must weigh these factors against efficiency gains, as diode rectification offers ease of implementation and lower component costs but suffers from higher conduction losses. Selecting synchronous rectification can improve energy efficiency and thermal performance but demands careful design and potentially higher production expenses.

Application Scenarios for Each Rectification Method

Synchronous rectification excels in high-efficiency power supplies, such as DC-DC converters in computers and electric vehicles, where minimizing power loss is crucial. Diode rectification remains effective in low-cost, low-current applications like simple AC adapters and basic power supplies where efficiency is less critical. Your choice depends on balancing efficiency demands and cost constraints within your specific application scenario.

Future Trends in Rectification Technology

Synchronous rectification is rapidly advancing due to its superior efficiency and reduced power loss compared to traditional diode rectification, making it a preferred choice in modern power electronics. Future trends emphasize integrating wide-bandgap semiconductors like GaN and SiC, which enable higher switching frequencies and improved thermal performance, further enhancing synchronous rectifier design. Your power systems will benefit from these innovations through enhanced energy conversion efficiency and reduced heat generation, driving the evolution of smarter, more compact rectification solutions.

synchronous rectification vs diode rectification Infographic

electrown.com

electrown.com