Isolated buck converters provide electrical separation between input and output, enhancing safety and reducing noise interference, while non-isolated buck converters offer simpler design and higher efficiency without galvanic isolation. Discover which buck converter best suits your power supply needs by exploring the detailed comparison in the rest of this article.

Table of Comparison

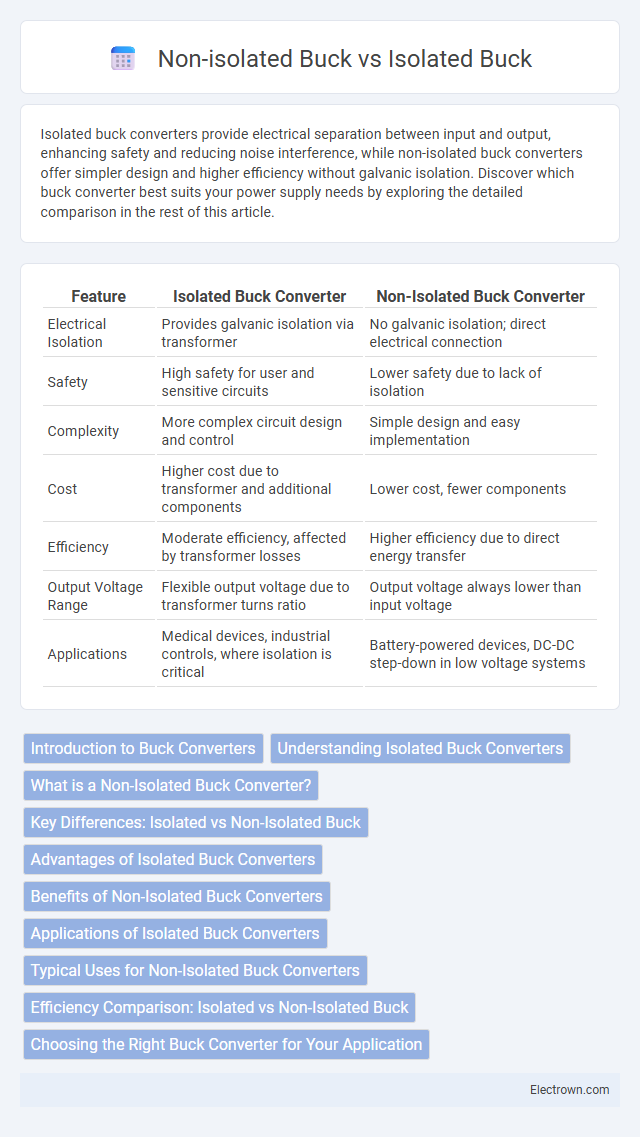

| Feature | Isolated Buck Converter | Non-Isolated Buck Converter |

|---|---|---|

| Electrical Isolation | Provides galvanic isolation via transformer | No galvanic isolation; direct electrical connection |

| Safety | High safety for user and sensitive circuits | Lower safety due to lack of isolation |

| Complexity | More complex circuit design and control | Simple design and easy implementation |

| Cost | Higher cost due to transformer and additional components | Lower cost, fewer components |

| Efficiency | Moderate efficiency, affected by transformer losses | Higher efficiency due to direct energy transfer |

| Output Voltage Range | Flexible output voltage due to transformer turns ratio | Output voltage always lower than input voltage |

| Applications | Medical devices, industrial controls, where isolation is critical | Battery-powered devices, DC-DC step-down in low voltage systems |

Introduction to Buck Converters

Buck converters efficiently step down voltage from a higher input to a lower output by switching elements and energy storage components. Isolated buck converters incorporate transformers to provide galvanic isolation and voltage scaling, enhancing safety and flexibility in applications requiring separation between input and output grounds. Non-isolated buck converters use direct electrical connections without isolation, offering simpler design, higher efficiency, and cost-effectiveness in low-voltage scenarios where isolation is not critical.

Understanding Isolated Buck Converters

Isolated buck converters use transformers to provide galvanic isolation between input and output, enhancing safety and reducing noise interference in sensitive applications. Non-isolated buck converters directly connect input and output grounds, offering simpler design and higher efficiency but lacking isolation benefits. Understanding isolated buck converters helps you choose the right power supply topology for critical systems requiring electrical isolation and reliable voltage regulation.

What is a Non-Isolated Buck Converter?

A non-isolated buck converter is a DC-DC step-down power supply that directly connects the input and output grounds, allowing efficient voltage reduction without the use of galvanic isolation components like transformers. It employs a high-speed switching transistor, an inductor, and a diode or synchronous rectifier to convert higher input voltage to a lower output voltage while maintaining continuous conduction mode for stable current flow. This design offers simpler circuitry, lower cost, and higher efficiency, making it ideal for applications requiring compact, reliable power conversion without the need for electrical isolation.

Key Differences: Isolated vs Non-Isolated Buck

Isolated buck converters provide electrical separation between input and output through a transformer, enhancing safety and reducing noise interference, whereas non-isolated buck converters have a direct electrical connection, offering simpler design and higher efficiency for low-voltage applications. The isolation in isolated buck converters enables higher voltage step-down flexibility and better protection in sensitive systems, while non-isolated types are typically smaller and more cost-effective. Your choice depends on the specific requirements for isolation, safety, and efficiency in your power supply design.

Advantages of Isolated Buck Converters

Isolated buck converters offer enhanced safety and noise immunity by physically separating the input and output grounds, which reduces the risk of ground loops and electrical interference in sensitive applications. They provide superior protection for downstream components through galvanic isolation, ensuring that high voltage spikes or faults do not propagate across the system. This isolation enables flexible system design choices, allowing different parts of the device to operate at varying voltage levels without direct electrical connection.

Benefits of Non-Isolated Buck Converters

Non-isolated buck converters offer a simpler design with fewer components, resulting in higher efficiency and reduced cost compared to isolated buck converters. They provide a direct electrical connection between input and output, enabling faster transient response and improved power density, making them ideal for applications requiring compact and efficient power regulation. Your system benefits from reduced size and complexity while maintaining reliable voltage step-down performance.

Applications of Isolated Buck Converters

Isolated buck converters are widely used in applications requiring electrical separation between input and output for safety, noise reduction, and ground loop elimination, such as medical devices, telecommunications, and industrial equipment. Your system benefits from isolated buck converters when galvanic isolation is critical to protect sensitive components and ensure compliance with regulatory standards. In contrast, non-isolated buck converters are preferred for simpler, cost-effective voltage step-down tasks where isolation is not necessary.

Typical Uses for Non-Isolated Buck Converters

Non-isolated buck converters are typically used in applications requiring efficient step-down voltage conversion within the same ground reference, such as in DC power supplies for microcontrollers, battery-powered devices, and consumer electronics. These converters are favored for their compact design, low cost, and high efficiency in powering low-voltage digital circuits from higher voltage sources. Non-isolated buck converters are ideal when electrical isolation is unnecessary, simplifying circuit design and reducing overall system complexity.

Efficiency Comparison: Isolated vs Non-Isolated Buck

Non-isolated buck converters typically achieve higher efficiency due to their simpler design, which minimizes energy losses by eliminating the need for additional isolation components such as transformers or optocouplers. Isolated buck converters, while providing enhanced safety and noise immunity through galvanic isolation, often experience slightly lower efficiency due to increased complexity and additional conversion stages. Your choice should weigh the efficiency benefits of non-isolated designs against the isolation requirements for specific applications.

Choosing the Right Buck Converter for Your Application

Isolated buck converters provide electrical separation between input and output, enhancing safety and noise reduction, making them ideal for medical or industrial applications requiring galvanic isolation. Non-isolated buck converters offer higher efficiency and simpler design, suited for low-voltage power supplies in consumer electronics or embedded systems. Selecting the right buck converter depends on factors such as isolation requirements, efficiency, size constraints, and application-specific safety standards.

Isolated buck vs Non-isolated buck Infographic

electrown.com

electrown.com