Piezo transformers utilize mechanical vibrations in piezoelectric materials to convert voltage, offering compact size and high efficiency ideal for low-power applications, whereas magnetic transformers rely on electromagnetic induction with coils and cores to handle higher power levels, often resulting in larger, heavier components. Explore the rest of this article to understand which transformer suits your specific needs and applications.

Table of Comparison

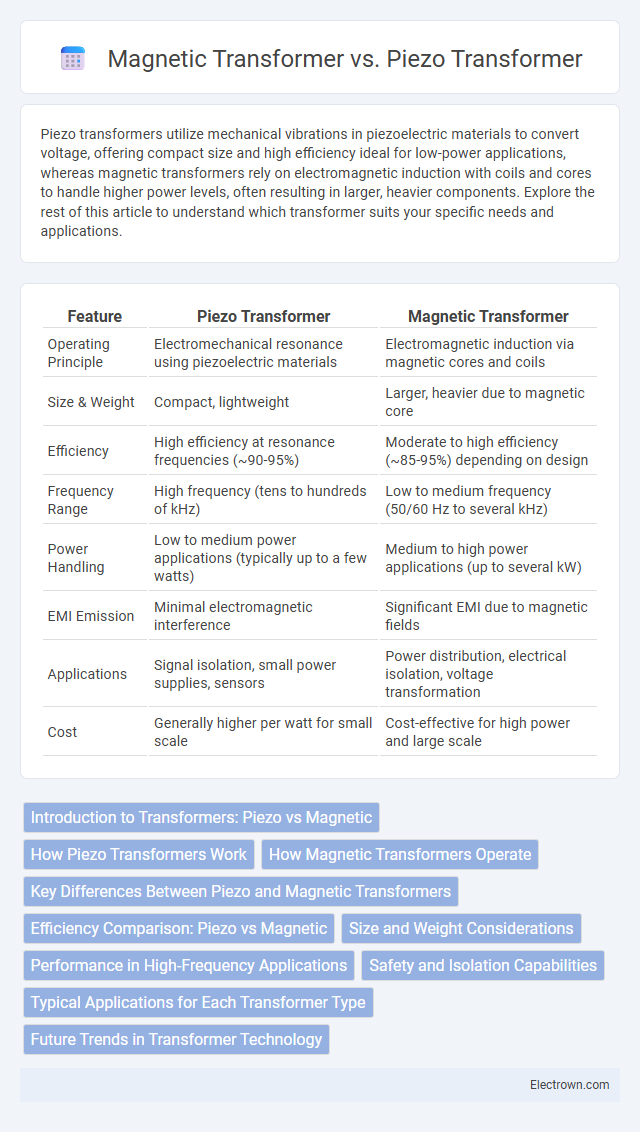

| Feature | Piezo Transformer | Magnetic Transformer |

|---|---|---|

| Operating Principle | Electromechanical resonance using piezoelectric materials | Electromagnetic induction via magnetic cores and coils |

| Size & Weight | Compact, lightweight | Larger, heavier due to magnetic core |

| Efficiency | High efficiency at resonance frequencies (~90-95%) | Moderate to high efficiency (~85-95%) depending on design |

| Frequency Range | High frequency (tens to hundreds of kHz) | Low to medium frequency (50/60 Hz to several kHz) |

| Power Handling | Low to medium power applications (typically up to a few watts) | Medium to high power applications (up to several kW) |

| EMI Emission | Minimal electromagnetic interference | Significant EMI due to magnetic fields |

| Applications | Signal isolation, small power supplies, sensors | Power distribution, electrical isolation, voltage transformation |

| Cost | Generally higher per watt for small scale | Cost-effective for high power and large scale |

Introduction to Transformers: Piezo vs Magnetic

Piezo transformers utilize the piezoelectric effect to convert electrical energy into mechanical vibrations, resulting in voltage transformation with high efficiency and compact design. Magnetic transformers rely on electromagnetic induction between coils to transfer energy, typically featuring larger size and heavier weight but proven reliability in various electrical applications. Your choice depends on factors like size constraints, efficiency requirements, and operating frequency, with piezo transformers excelling in high-frequency, lightweight scenarios, while magnetic transformers remain dominant in power distribution and low-frequency uses.

How Piezo Transformers Work

Piezo transformers operate by converting electrical energy into mechanical vibrations using piezoelectric materials and then back into electrical energy at a different voltage, enabling efficient voltage transformation with minimal electromagnetic interference. Unlike magnetic transformers that rely on magnetic cores and coils, piezo transformers use mechanical resonance, providing compact size and high-frequency operation ideal for sensitive electronic applications. Your choice of a piezo transformer ensures reduced energy loss and enhanced performance in low-power, high-precision circuits.

How Magnetic Transformers Operate

Magnetic transformers operate by transferring electrical energy between circuits through electromagnetic induction, utilizing coils wrapped around a magnetic core to efficiently step voltage up or down. The magnetic core concentrates the magnetic flux generated by current in the primary coil, inducing a voltage in the secondary coil according to the turns ratio. Your choice between piezo transformers and magnetic transformers depends on factors like size, efficiency, and application-specific voltage requirements.

Key Differences Between Piezo and Magnetic Transformers

Piezo transformers utilize mechanical vibrations to transfer energy, offering higher efficiency, compact size, and reduced electromagnetic interference compared to traditional magnetic transformers that rely on electromagnetic induction. Magnetic transformers tend to be bulkier, heavier, and produce more electromagnetic noise, making piezo transformers ideal for applications requiring precision and minimal signal disturbance. Your choice between these technologies depends on factors like power requirements, size constraints, and noise sensitivity.

Efficiency Comparison: Piezo vs Magnetic

Piezo transformers typically exhibit higher efficiency than magnetic transformers at high frequencies due to lower core losses and reduced electromagnetic interference. Magnetic transformers, while robust and widely used, suffer from energy loss in the form of heat generated by iron core hysteresis and eddy currents. Your choice of transformer impacts overall system efficiency, especially in compact, high-frequency applications where piezo transformers can offer superior energy conversion performance.

Size and Weight Considerations

Piezo transformers are significantly smaller and lighter than magnetic transformers due to their solid-state construction and absence of magnetic cores. Their compact size makes them ideal for applications with strict space and weight limitations, such as portable electronics or medical devices. Choosing a piezo transformer can optimize Your design by reducing overall device dimensions and improving energy efficiency.

Performance in High-Frequency Applications

Piezo transformers offer superior performance in high-frequency applications due to their low electromagnetic interference and high efficiency at frequencies above 100 kHz. Unlike magnetic transformers, which suffer from core losses and limited operating frequency ranges typically below 500 kHz, piezo transformers maintain stable voltage conversion with minimal heat generation. Their compact size and ability to operate efficiently in the MHz range make them ideal for advanced power supply and signal processing systems requiring fast response times and high power density.

Safety and Isolation Capabilities

Piezo transformers offer superior safety due to their inherent galvanic isolation and absence of electromagnetic interference, reducing the risk of electric shock and enhancing noise immunity. Magnetic transformers rely on magnetic cores and coils which can introduce leakage currents and electromagnetic emissions, potentially compromising isolation in sensitive applications. The compact design and ceramic materials of piezo transformers further improve dielectric strength and insulation compared to traditional magnetic transformers.

Typical Applications for Each Transformer Type

Piezo transformers are commonly used in applications requiring compact size, high-frequency operation, and electrical isolation, such as in LCD backlighting, energy harvesting devices, and precision sensors. Magnetic transformers excel in power distribution, voltage step-up or step-down tasks, and isolation in industrial equipment, power supplies, and audio devices due to their ability to handle high power levels efficiently. Understanding the application environment helps you select the most suitable transformer type for optimal performance and reliability.

Future Trends in Transformer Technology

Piezo transformers are gaining traction for their compact size, high efficiency, and ability to operate at higher frequencies, positioning them as a promising alternative to traditional magnetic transformers in next-generation electronics. Future trends emphasize integrating piezoelectric materials with advanced semiconductor technology to enhance power density and reduce electromagnetic interference. Your choice between piezo and magnetic transformers will likely depend on the evolving demands for miniaturization, energy efficiency, and environmental sustainability in transformer applications.

piezo transformer vs magnetic transformer Infographic

electrown.com

electrown.com