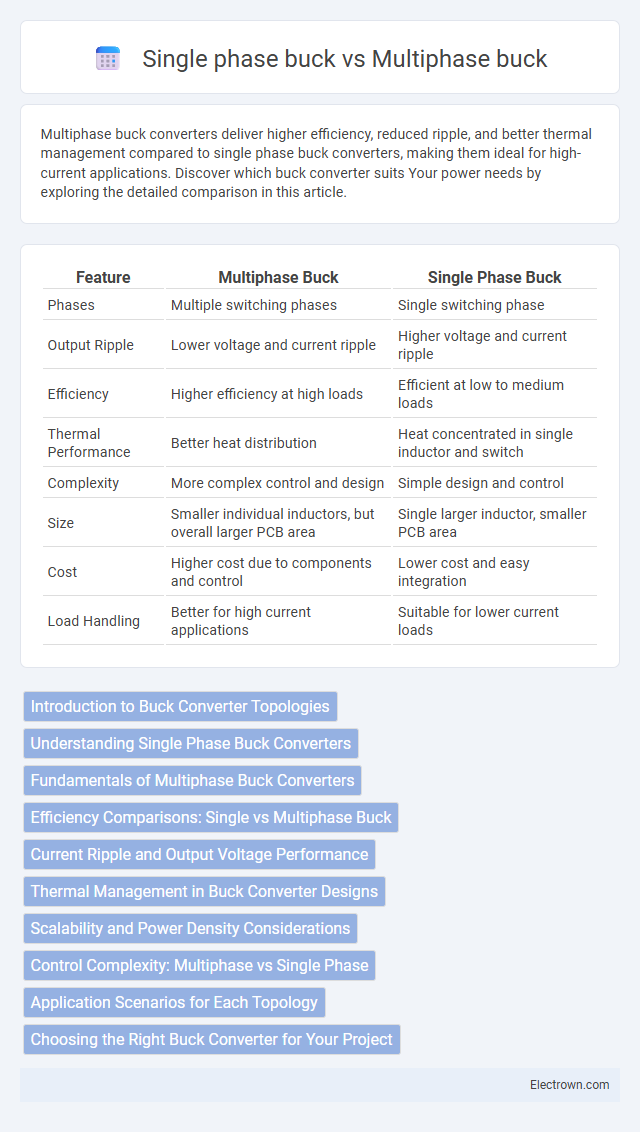

Multiphase buck converters deliver higher efficiency, reduced ripple, and better thermal management compared to single phase buck converters, making them ideal for high-current applications. Discover which buck converter suits Your power needs by exploring the detailed comparison in this article.

Table of Comparison

| Feature | Multiphase Buck | Single Phase Buck |

|---|---|---|

| Phases | Multiple switching phases | Single switching phase |

| Output Ripple | Lower voltage and current ripple | Higher voltage and current ripple |

| Efficiency | Higher efficiency at high loads | Efficient at low to medium loads |

| Thermal Performance | Better heat distribution | Heat concentrated in single inductor and switch |

| Complexity | More complex control and design | Simple design and control |

| Size | Smaller individual inductors, but overall larger PCB area | Single larger inductor, smaller PCB area |

| Cost | Higher cost due to components and control | Lower cost and easy integration |

| Load Handling | Better for high current applications | Suitable for lower current loads |

Introduction to Buck Converter Topologies

Multiphase buck converters distribute current across multiple phases, reducing ripple and improving efficiency compared to single phase buck converters which rely on a single switching element. Your choice between single phase and multiphase buck topologies affects thermal management, output voltage stability, and transient response in power delivery systems. Multiphase designs are particularly advantageous for high-current applications requiring lower input/output voltage differentials and enhanced EMI performance.

Understanding Single Phase Buck Converters

Single phase buck converters regulate voltage by switching a single inductor and transistor, making them simpler but less efficient at higher currents compared to multiphase designs. Your power supply design benefits from single phase buck converters due to their straightforward control and lower electromagnetic interference in low to moderate current applications. However, they may experience higher ripple voltages and thermal stress than multiphase buck converters, which distribute the load across multiple phases for improved performance.

Fundamentals of Multiphase Buck Converters

Multiphase buck converters use multiple synchronized switching phases to reduce input current ripple and improve thermal performance compared to single phase buck converters. By interleaving several buck converter phases, they achieve lower output voltage ripple and higher efficiency in power delivery, ideal for high-current applications like CPUs and GPUs. Your power system benefits from enhanced transient response and reduced electromagnetic interference with a well-designed multiphase buck converter architecture.

Efficiency Comparisons: Single vs Multiphase Buck

Multiphase buck converters offer higher efficiency than single-phase bucks by distributing current across multiple phases, reducing conduction losses and thermal stress. Your system benefits from improved transient response and better thermal management, enabling higher power density and reliability. Single-phase buck converters, while simpler, typically experience greater power loss under heavy loads due to concentrated current flow and higher ripple.

Current Ripple and Output Voltage Performance

Multiphase buck converters significantly reduce current ripple by distributing the load across multiple phases, resulting in smoother input current and enhanced efficiency compared to single-phase buck converters. This improved current ripple management leads to better output voltage regulation and lower voltage ripple, which is critical for sensitive electronic applications. In contrast, single-phase buck converters experience higher current ripple and voltage fluctuations due to the reliance on a single switching element.

Thermal Management in Buck Converter Designs

Multiphase buck converters distribute current load across multiple phases, significantly reducing thermal stress compared to single-phase buck converters by lowering individual component currents and spreading heat dissipation. Enhanced thermal management in multiphase designs leads to improved efficiency, extended component lifespan, and more compact PCB layouts due to reduced need for bulky heat sinks. In contrast, single-phase buck converters concentrate heat in fewer components, often requiring extensive cooling solutions to prevent thermal runaway and maintain stable operation.

Scalability and Power Density Considerations

Multiphase buck converters offer superior scalability and power density compared to single-phase buck designs by distributing current across multiple phases, reducing thermal stress and enabling smaller inductors and capacitors. This parallel operation enhances transient response and efficiency, allowing your power supply to handle higher loads without compromising size or performance. Single-phase buck converters, while simpler, are limited in scalability and typically require larger components to manage equivalent power levels, resulting in lower overall power density.

Control Complexity: Multiphase vs Single Phase

Multiphase buck converters exhibit higher control complexity compared to single-phase buck converters due to the need for phase interleaving and precise current balancing among multiple phases. The control algorithms for multiphase designs must manage phase synchronization, transient response coordination, and load sharing to optimize efficiency and reduce output ripple. Single-phase buck converters feature simpler control schemes centered on a single switching element, making their design and implementation less intricate.

Application Scenarios for Each Topology

Multiphase buck converters are ideal for high-current applications such as CPUs, GPUs, and power-intensive data centers where efficient heat dissipation and reduced input/output ripple are critical. Single-phase buck converters better suit low to moderate power devices like small microcontrollers, sensors, and battery-powered gadgets due to their simpler design and lower cost. The choice hinges on current requirements, thermal management, and noise sensitivity, making multiphase optimal for demanding power regulation and single-phase preferred for compact, less complex systems.

Choosing the Right Buck Converter for Your Project

Multiphase buck converters offer higher efficiency and better thermal management compared to single-phase buck converters, making them ideal for high-current and low-voltage applications in your project. Single-phase buck converters are simpler, cost-effective, and sufficient for low to moderate power requirements, ensuring ease of implementation and reduced complexity. When choosing the right buck converter, consider your project's current demand, efficiency needs, and thermal constraints to optimize performance and reliability.

Multiphase buck vs Single phase buck Infographic

electrown.com

electrown.com