Auto transformers share a single winding for both primary and secondary circuits, offering higher efficiency and cost savings, while isolation transformers have separate windings providing complete electrical separation for enhanced safety and noise reduction. Explore the rest of the article to understand which transformer suits your specific electrical needs best.

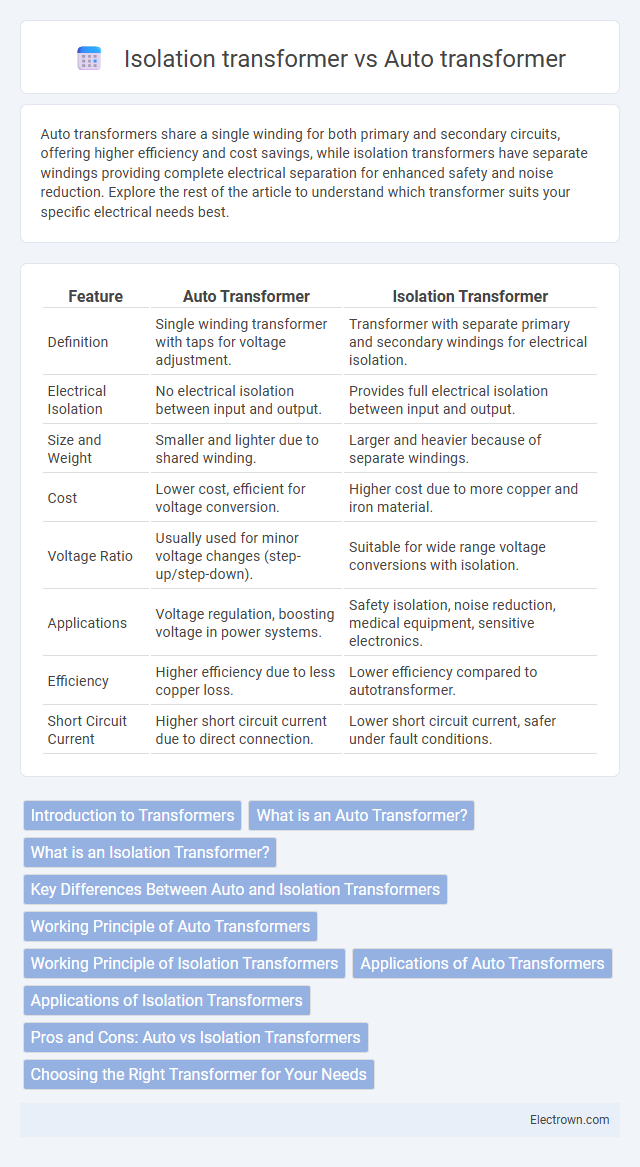

Table of Comparison

| Feature | Auto Transformer | Isolation Transformer |

|---|---|---|

| Definition | Single winding transformer with taps for voltage adjustment. | Transformer with separate primary and secondary windings for electrical isolation. |

| Electrical Isolation | No electrical isolation between input and output. | Provides full electrical isolation between input and output. |

| Size and Weight | Smaller and lighter due to shared winding. | Larger and heavier because of separate windings. |

| Cost | Lower cost, efficient for voltage conversion. | Higher cost due to more copper and iron material. |

| Voltage Ratio | Usually used for minor voltage changes (step-up/step-down). | Suitable for wide range voltage conversions with isolation. |

| Applications | Voltage regulation, boosting voltage in power systems. | Safety isolation, noise reduction, medical equipment, sensitive electronics. |

| Efficiency | Higher efficiency due to less copper loss. | Lower efficiency compared to autotransformer. |

| Short Circuit Current | Higher short circuit current due to direct connection. | Lower short circuit current, safer under fault conditions. |

Introduction to Transformers

Transformers are electrical devices designed to transfer electrical energy between circuits through electromagnetic induction. An Auto transformer uses a single winding that acts as both the primary and secondary, sharing part of the coil, resulting in a more compact and efficient design for voltage regulation. In contrast, an Isolation transformer features separate primary and secondary windings, providing electrical isolation and enhancing safety by preventing direct electrical connection between input and output circuits.

What is an Auto Transformer?

An auto transformer is a single-winding transformer where a portion of the winding is common to both the primary and secondary circuits, enabling voltage transformation with increased efficiency and reduced size compared to isolation transformers. It provides voltage step-up or step-down by tapping into different points on the same coil, making it suitable for applications requiring small voltage adjustments. Unlike isolation transformers, auto transformers do not provide electrical isolation between primary and secondary sides, which limits their use in safety-critical scenarios.

What is an Isolation Transformer?

An Isolation Transformer is a device designed to electrically separate the input power source from the output load, providing safety by isolating your equipment from direct contact with the primary power supply. Unlike Auto Transformers, isolation transformers have separate primary and secondary windings, which minimizes the risk of electric shock and reduces noise and interference in sensitive electronic devices. This electrical isolation ensures enhanced protection for critical applications and prevents ground loop problems.

Key Differences Between Auto and Isolation Transformers

Auto transformers share a single winding that acts as both primary and secondary, enabling voltage adjustment with higher efficiency and a smaller size, whereas isolation transformers have separate primary and secondary windings providing galvanic isolation for improved safety. Isolation transformers prevent direct electrical connection between input and output, reducing noise and protecting against electric shocks, while auto transformers do not offer isolation but are more cost-effective for voltage step-up or step-down applications. The key difference lies in electrical isolation, with isolation transformers ensuring safer operation in sensitive equipment, and auto transformers offering compact design and efficiency where isolation is not required.

Working Principle of Auto Transformers

Auto transformers operate by sharing a portion of their winding between the primary and secondary circuits, utilizing electromagnetic induction to transfer electrical energy. Unlike isolation transformers, they have a single continuous winding with taps at different points to adjust voltage levels, improving efficiency and reducing size and cost. This working principle allows auto transformers to provide voltage transformation with a common winding, but without electrical isolation between input and output.

Working Principle of Isolation Transformers

Isolation transformers operate by magnetically coupling the primary and secondary windings without a direct electrical connection, ensuring electrical isolation between input and output. They transfer power through electromagnetic induction, which effectively blocks noise, reduces ground loops, and enhances safety by isolating your devices from the main power supply. This principle makes them essential for sensitive electronic equipment requiring clean power and protection from electrical faults.

Applications of Auto Transformers

Auto transformers are commonly used in voltage regulation, motor starting, and power distribution systems due to their efficiency and cost-effectiveness. These transformers are ideal for applications requiring variable voltage adjustments or where isolation from the supply is not critical. Your equipment can benefit from the compact size and reduced copper usage of auto transformers, especially in scenarios such as voltage boosting or bucking in industrial machinery.

Applications of Isolation Transformers

Isolation transformers are commonly used in medical equipment to ensure patient safety by preventing electric shock through galvanic isolation. They are also essential in industrial settings for protecting sensitive instrumentation and control systems from electrical noise and voltage spikes. Furthermore, isolation transformers are employed in audio and telecommunication equipment to reduce ground loops and enhance signal integrity.

Pros and Cons: Auto vs Isolation Transformers

Auto transformers offer higher efficiency and smaller size due to their shared winding design, making them cost-effective for voltage adjustment applications where isolation is not critical. However, they lack galvanic isolation, exposing connected equipment to potential electrical faults and limiting their use in sensitive or safety-critical environments. In contrast, isolation transformers provide complete electrical separation between primary and secondary circuits, enhancing safety by preventing ground loops and electrical shocks, but they are typically bulkier, more expensive, and less efficient due to separate windings.

Choosing the Right Transformer for Your Needs

Choosing the right transformer depends on your specific electrical requirements, where an auto transformer offers a cost-effective and efficient solution for voltage regulation within a limited range, ideal for applications with similar input and output voltages. Isolation transformers provide superior safety by electrically separating the input and output, making them essential for sensitive equipment or environments requiring noise reduction and fault isolation. Understanding whether your primary need is voltage adjustment or electrical isolation will guide you to the best choice for your system's performance and safety.

Auto transformer vs Isolation transformer Infographic

electrown.com

electrown.com