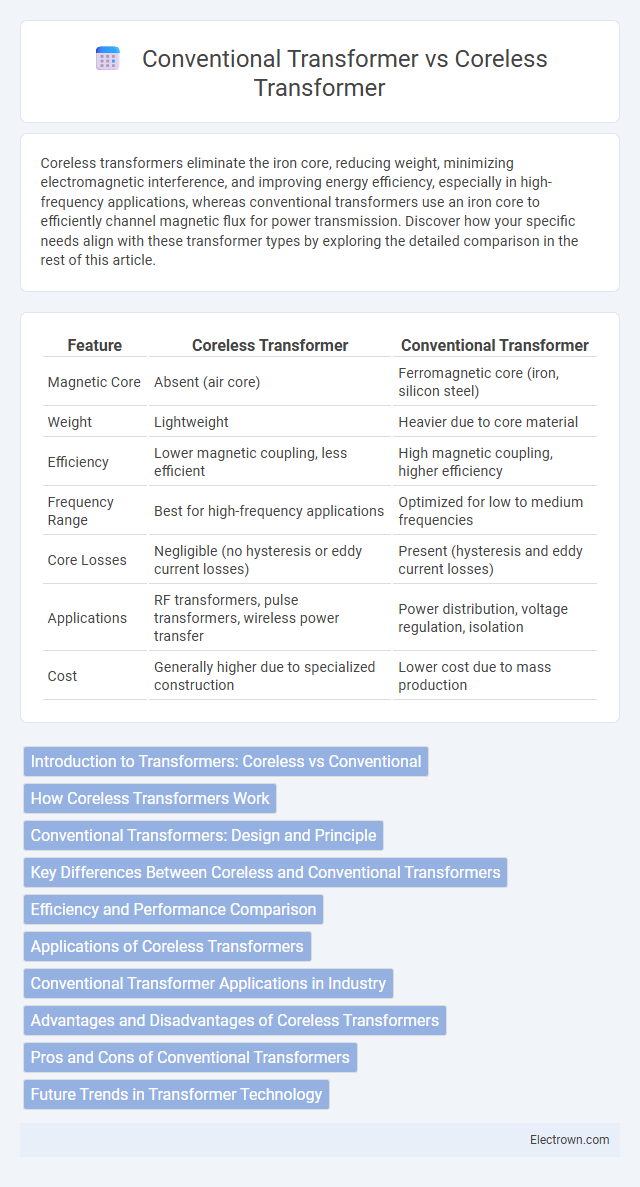

Coreless transformers eliminate the iron core, reducing weight, minimizing electromagnetic interference, and improving energy efficiency, especially in high-frequency applications, whereas conventional transformers use an iron core to efficiently channel magnetic flux for power transmission. Discover how your specific needs align with these transformer types by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | Coreless Transformer | Conventional Transformer |

|---|---|---|

| Magnetic Core | Absent (air core) | Ferromagnetic core (iron, silicon steel) |

| Weight | Lightweight | Heavier due to core material |

| Efficiency | Lower magnetic coupling, less efficient | High magnetic coupling, higher efficiency |

| Frequency Range | Best for high-frequency applications | Optimized for low to medium frequencies |

| Core Losses | Negligible (no hysteresis or eddy current losses) | Present (hysteresis and eddy current losses) |

| Applications | RF transformers, pulse transformers, wireless power transfer | Power distribution, voltage regulation, isolation |

| Cost | Generally higher due to specialized construction | Lower cost due to mass production |

Introduction to Transformers: Coreless vs Conventional

Coreless transformers use air or non-magnetic materials as the core, reducing energy losses and electromagnetic interference, making them ideal for high-frequency applications. Conventional transformers feature magnetic cores made from laminated silicon steel, enhancing magnetic flux efficiency and enabling higher power transfer for low-frequency, high-load conditions. The choice between coreless and conventional transformers depends on application requirements such as frequency, efficiency, size, and electromagnetic compatibility.

How Coreless Transformers Work

Coreless transformers operate using air or non-magnetic materials instead of traditional iron cores, relying on tightly wound coils to generate magnetic fields through electromagnetic induction. This design minimizes core losses, reduces noise, and enables high-frequency operation with greater efficiency. Without a ferromagnetic core, coreless transformers offer lighter weight and improved thermal performance while maintaining effective energy transfer between primary and secondary windings.

Conventional Transformers: Design and Principle

Conventional transformers consist of laminated iron cores that provide a low-reluctance path for magnetic flux, enhancing energy transfer between primary and secondary windings. Their design relies on Faraday's law of electromagnetic induction, where alternating current in the primary coil generates a varying magnetic flux in the iron core, inducing voltage in the secondary coil. You benefit from efficient voltage transformation and minimal energy loss, making conventional transformers ideal for power distribution systems.

Key Differences Between Coreless and Conventional Transformers

Coreless transformers eliminate the iron core, resulting in reduced weight, lower electromagnetic interference, and higher frequency operation compared to conventional transformers with laminated steel cores. Conventional transformers rely on the magnetic properties of the core to achieve high efficiency and voltage regulation, whereas coreless designs sacrifice some efficiency for faster response and compact size. Your choice depends on specific application needs like size constraints, frequency range, and sensitivity to magnetic fields.

Efficiency and Performance Comparison

Coreless transformers offer improved efficiency over conventional transformers by eliminating core losses such as hysteresis and eddy currents, resulting in reduced energy dissipation and heat generation. Their design allows for higher frequency operation, enhancing performance in applications like power electronics and wireless charging where size and weight are critical. Conventional transformers, while generally robust and cost-effective, exhibit lower efficiency at high frequencies due to core material limitations and increased core losses.

Applications of Coreless Transformers

Coreless transformers excel in applications requiring minimal electromagnetic interference and lightweight design, such as biomedical devices, wireless power transfer, and precision instrumentation. Their air-core structure enables high-frequency operation and rapid response times, making them ideal for sensitive electronic circuits and pulse transformers. Your choice of a coreless transformer enhances performance in environments where low magnetic flux and compact size are essential.

Conventional Transformer Applications in Industry

Conventional transformers are extensively used in industries for voltage regulation, power distribution, and electrical isolation due to their robust iron-core design that efficiently handles high power levels. Applications include heavy machinery operation, manufacturing plants, and power grids where maintaining stable voltage and reducing energy loss are critical. Their ability to provide reliable performance at high frequencies and voltages makes them indispensable in industrial power systems.

Advantages and Disadvantages of Coreless Transformers

Coreless transformers offer reduced electromagnetic interference and eliminate core losses, making them ideal for high-frequency applications and improving energy efficiency. Their lightweight and compact design provide greater flexibility in portable devices, but they generally exhibit lower inductance and power handling capacity compared to conventional transformers with iron cores. You should weigh these benefits against the potential trade-offs in voltage regulation and cost when selecting the appropriate transformer type.

Pros and Cons of Conventional Transformers

Conventional transformers with iron cores offer high magnetic permeability, which enhances efficiency and minimizes energy loss through improved flux conduction. Their robust design ensures durability and stable voltage regulation, but the iron core causes increased weight and hysteresis losses, leading to noise and heat generation. You may find conventional transformers less suitable for lightweight or high-frequency applications due to their bulk and core-related losses.

Future Trends in Transformer Technology

Coreless transformers, characterized by reduced electromagnetic losses and enhanced efficiency, are increasingly adopted in compact electronics and renewable energy systems, signaling a shift toward eco-friendly and lightweight solutions. Conventional transformers, while still prevalent in high-power applications for their robust performance and reliability, are gradually integrating advanced materials and smart monitoring technologies to improve efficiency and operational lifespan. Your choice between coreless and conventional transformers should consider emerging trends like energy-efficient designs, IoT-enabled diagnostics, and sustainability requirements shaping the future of transformer technology.

coreless transformer vs conventional transformer Infographic

electrown.com

electrown.com