Dielectric resonator oscillators (DROs) offer higher frequency stability and lower phase noise compared to quartz oscillators, making them ideal for microwave and high-frequency applications where precision is crucial. Discover how understanding the differences between these oscillators can enhance Your electronic designs by reading the rest of the article.

Table of Comparison

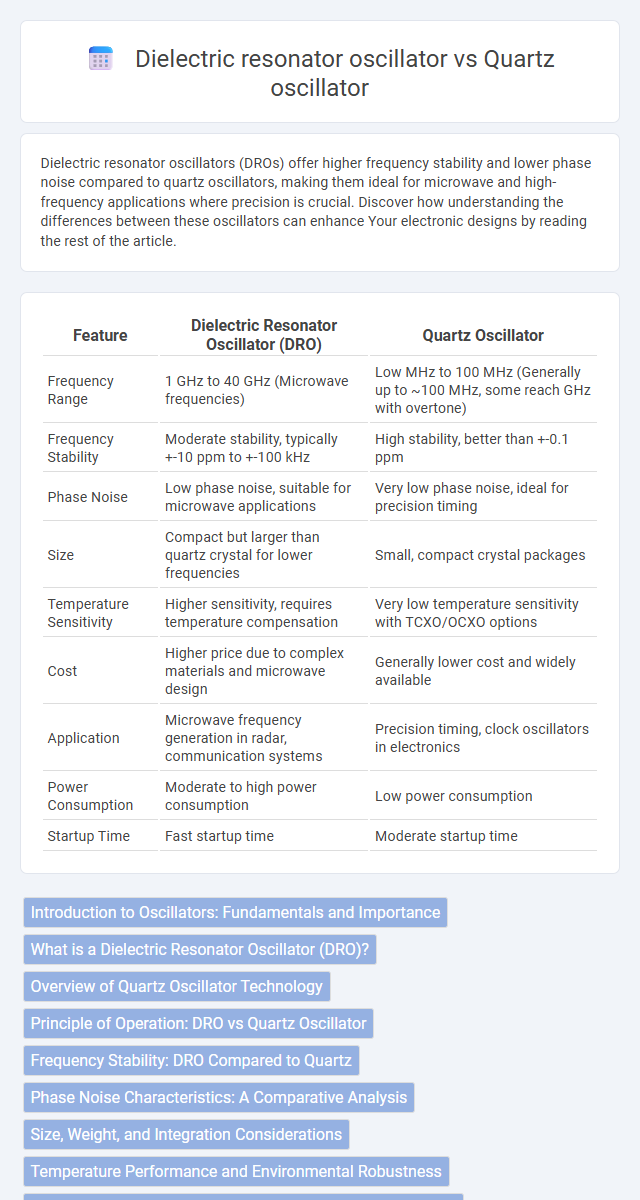

| Feature | Dielectric Resonator Oscillator (DRO) | Quartz Oscillator |

|---|---|---|

| Frequency Range | 1 GHz to 40 GHz (Microwave frequencies) | Low MHz to 100 MHz (Generally up to ~100 MHz, some reach GHz with overtone) |

| Frequency Stability | Moderate stability, typically +-10 ppm to +-100 kHz | High stability, better than +-0.1 ppm |

| Phase Noise | Low phase noise, suitable for microwave applications | Very low phase noise, ideal for precision timing |

| Size | Compact but larger than quartz crystal for lower frequencies | Small, compact crystal packages |

| Temperature Sensitivity | Higher sensitivity, requires temperature compensation | Very low temperature sensitivity with TCXO/OCXO options |

| Cost | Higher price due to complex materials and microwave design | Generally lower cost and widely available |

| Application | Microwave frequency generation in radar, communication systems | Precision timing, clock oscillators in electronics |

| Power Consumption | Moderate to high power consumption | Low power consumption |

| Startup Time | Fast startup time | Moderate startup time |

Introduction to Oscillators: Fundamentals and Importance

Dielectric resonator oscillators (DROs) utilize high-permittivity ceramic materials to achieve stable resonance frequencies with low phase noise, whereas quartz oscillators rely on the piezoelectric properties of quartz crystals for precise frequency control and long-term stability. Both oscillator types play crucial roles in signal generation and frequency reference applications, with DROs favored in high-frequency microwave circuits and quartz oscillators prevalent in clock generation for timekeeping and telecommunications. Understanding the fundamentals of these oscillators highlights their importance in maintaining signal integrity and synchronization across a wide range of electronic systems.

What is a Dielectric Resonator Oscillator (DRO)?

A Dielectric Resonator Oscillator (DRO) is a high-frequency oscillator that utilizes a dielectric resonator to generate stable microwave signals with low phase noise. Its core component is a ceramic dielectric resonator that provides a high-quality factor (Q) resonance, enabling precise frequency control mainly in the GHz range. DROs are widely used in applications such as radar, communication systems, and test equipment requiring compact size and superior frequency stability compared to quartz oscillators at microwave frequencies.

Overview of Quartz Oscillator Technology

Quartz oscillator technology uses piezoelectric quartz crystals to generate highly stable and precise frequencies by exploiting the crystal's mechanical resonance. This technology is crucial in applications requiring low phase noise and temperature stability, such as clocks, radios, and communication devices. You benefit from quartz oscillators' excellent frequency accuracy and long-term stability compared to dielectric resonator oscillators.

Principle of Operation: DRO vs Quartz Oscillator

Dielectric resonator oscillators (DROs) use a dielectric resonator made of ceramic material to generate oscillations through electromagnetic resonance at microwave frequencies, offering high frequency stability and low phase noise. Quartz oscillators rely on the piezoelectric effect of quartz crystals, where mechanical vibrations within the crystal produce highly stable oscillations primarily at lower frequencies. The DRO principle is based on electromagnetic resonance in dielectric materials, while quartz oscillators depend on the mechanical resonance of the quartz crystal lattice.

Frequency Stability: DRO Compared to Quartz

Dielectric resonator oscillators (DROs) offer excellent frequency stability with low phase noise, making them suitable for microwave and high-frequency applications, while quartz oscillators generally provide superior long-term frequency stability due to their intrinsic material properties and lower temperature coefficients. DROs exhibit frequency stability typically in the range of 10^-8 to 10^-9 over temperature variations, whereas quartz oscillators can achieve stability levels down to 10^-10 or better with temperature compensation. The choice between DRO and quartz oscillators depends on the required frequency range and the environmental conditions influencing stability performance.

Phase Noise Characteristics: A Comparative Analysis

Dielectric resonator oscillators (DROs) exhibit lower phase noise at high frequencies due to their high Q-factor dielectric materials, making them ideal for microwave applications. Quartz oscillators offer superior phase noise performance at lower frequencies, benefiting from the piezoelectric properties of quartz crystals that provide exceptional frequency stability. Comparing phase noise, DROs excel above several GHz, while quartz oscillators dominate in the low MHz to hundreds of MHz range.

Size, Weight, and Integration Considerations

Dielectric resonator oscillators (DROs) are significantly smaller and lighter than quartz oscillators due to the compact nature of dielectric materials and their minimal packaging requirements. DROs allow easier integration into high-frequency circuits and modules because of their planar form factor, while quartz oscillators often require larger enclosures and more substantial mounting structures. This size and weight benefit makes DROs preferable in applications demanding miniaturization and high integration density, such as modern communication equipment and radar systems.

Temperature Performance and Environmental Robustness

Dielectric resonator oscillators (DROs) offer superior temperature performance with minimal frequency drift across a wide temperature range, making them ideal for stable applications under varying thermal conditions. Quartz oscillators, while precise, tend to exhibit greater frequency fluctuations as temperature changes, requiring additional compensation circuits for enhanced stability. Your choice depends on the environmental robustness needed; DROs withstand harsher environments with better resistance to vibration and humidity compared to quartz oscillators.

Application Areas: Where DROs and Quartz Oscillators Excel

Dielectric resonator oscillators (DROs) excel in high-frequency applications such as radar systems, satellite communications, and microwave transmitters due to their superior phase noise performance and frequency stability at microwave bands. Quartz oscillators are preferred in precision timing devices, clocks, and low-frequency communication systems for their exceptional frequency accuracy and long-term stability. Your choice between DRO and quartz oscillators depends largely on the specific frequency requirements and environmental conditions of your application.

Choosing the Right Oscillator: Key Decision Factors

Dielectric resonator oscillators (DROs) offer superior frequency stability and low phase noise, making them ideal for high-frequency RF applications, whereas quartz oscillators excel in cost-effectiveness and long-term frequency accuracy for lower-frequency uses. Key decision factors include operating frequency range, phase noise requirements, temperature stability, size constraints, and environmental robustness. Selecting the right oscillator depends on balancing performance needs with application-specific parameters such as signal purity and budget limitations.

Dielectric resonator oscillator vs quartz oscillator Infographic

electrown.com

electrown.com