GaAs FETs excel in high-frequency applications due to their superior electron mobility and lower noise figure, making them ideal for microwave and RF amplifiers, while SiGe HBTs offer better linearity and integration with silicon-based circuits, enhancing digital and analog performance in mixed-signal environments. Discover the detailed comparisons and understand which technology suits Your specific application needs by reading the full article.

Table of Comparison

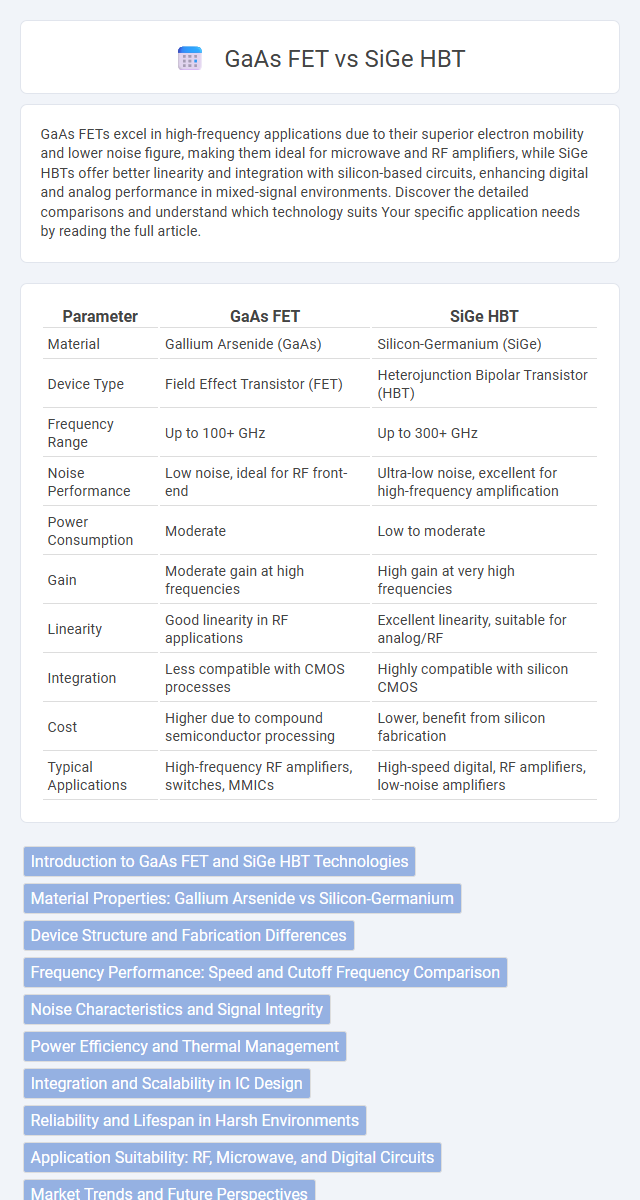

| Parameter | GaAs FET | SiGe HBT |

|---|---|---|

| Material | Gallium Arsenide (GaAs) | Silicon-Germanium (SiGe) |

| Device Type | Field Effect Transistor (FET) | Heterojunction Bipolar Transistor (HBT) |

| Frequency Range | Up to 100+ GHz | Up to 300+ GHz |

| Noise Performance | Low noise, ideal for RF front-end | Ultra-low noise, excellent for high-frequency amplification |

| Power Consumption | Moderate | Low to moderate |

| Gain | Moderate gain at high frequencies | High gain at very high frequencies |

| Linearity | Good linearity in RF applications | Excellent linearity, suitable for analog/RF |

| Integration | Less compatible with CMOS processes | Highly compatible with silicon CMOS |

| Cost | Higher due to compound semiconductor processing | Lower, benefit from silicon fabrication |

| Typical Applications | High-frequency RF amplifiers, switches, MMICs | High-speed digital, RF amplifiers, low-noise amplifiers |

Introduction to GaAs FET and SiGe HBT Technologies

GaAs FET (Gallium Arsenide Field-Effect Transistor) technology leverages the high electron mobility of gallium arsenide to achieve superior high-frequency performance and low noise, making it ideal for RF and microwave applications. SiGe HBT (Silicon-Germanium Heterojunction Bipolar Transistor) technology integrates silicon-germanium alloys into bipolar transistors, enhancing carrier mobility and enabling higher speed and gain while maintaining compatibility with standard silicon CMOS processes. Both technologies serve critical roles in high-speed communication systems, with GaAs FET excelling in power and frequency, and SiGe HBT offering cost-effective integration and thermal stability.

Material Properties: Gallium Arsenide vs Silicon-Germanium

Gallium Arsenide (GaAs) exhibits higher electron mobility and direct bandgap characteristics, enabling faster switching speeds and lower noise in FET devices compared to Silicon-Germanium (SiGe) HBTs. SiGe offers better compatibility with silicon CMOS processes and improved thermal conductivity, making it suitable for integrated circuits requiring high-frequency performance and thermal stability. Your choice between GaAs FET and SiGe HBT hinges on prioritizing superior electron mobility and speed versus integration capabilities and temperature resilience.

Device Structure and Fabrication Differences

GaAs FETs utilize a field-effect transistor structure with a metal-semiconductor interface forming the gate, relying on high electron mobility in the GaAs channel for fast switching, while SiGe HBTs employ bipolar junction transistors with a silicon-germanium alloy base designed for improved carrier injection and high-frequency performance. Fabrication of GaAs FETs involves epitaxial growth of GaAs layers and complex ion implantation to define the channel and contacts, whereas SiGe HBT fabrication integrates silicon-germanium epitaxy within standard silicon CMOS processes, enabling better compatibility with large-scale silicon manufacturing. The structural distinction in GaAs FETs leads to lower noise figures and high electron velocity, whereas the doped heterojunction in SiGe HBTs enhances current gain and breakdown voltage, optimizing device performance for different RF applications.

Frequency Performance: Speed and Cutoff Frequency Comparison

GaAs FETs exhibit superior frequency performance with cutoff frequencies (fT) often exceeding 100 GHz, making them ideal for ultra-high-speed applications in microwave and millimeter-wave domains. SiGe HBTs, while typically offering lower fT values around 200 GHz at best, provide better integration with silicon-based technologies and improved linearity in RF circuits. The inherent high electron mobility in GaAs devices enables faster switching speeds compared to the heterojunction bandgap engineering in SiGe HBTs, which optimize noise performance rather than maximum speed.

Noise Characteristics and Signal Integrity

GaAs FETs exhibit lower noise figures and superior high-frequency performance compared to SiGe HBTs, making them ideal for ultra-low noise amplifiers in sensitive RF applications. SiGe HBTs offer better linearity and gain stability, enhancing signal integrity in complex communication systems. Understanding these noise characteristics helps you select the appropriate transistor for optimized signal fidelity and system performance.

Power Efficiency and Thermal Management

GaAs FETs demonstrate higher power efficiency due to their superior electron mobility, enabling faster switching speeds and lower power dissipation compared to SiGe HBTs. SiGe HBTs excel in thermal management with better heat tolerance and robust operation at elevated temperatures, making them suitable for high-power applications requiring reliable thermal stability. Your choice between GaAs FET and SiGe HBT will depend on the balance between the need for power efficiency and effective thermal management in your specific application.

Integration and Scalability in IC Design

GaAs FETs offer superior high-frequency performance but face challenges in integration density and scalability compared to SiGe HBTs, which benefit from mature silicon processing technology enabling seamless integration with standard CMOS circuits. SiGe HBTs provide better scalability for complex IC designs due to their compatibility with advanced lithography and wafer fabrication techniques, resulting in lower production costs and enhanced yield. Your choice between GaAs FET and SiGe HBT depends on the required balance between high-frequency performance and integration density within the IC design constraints.

Reliability and Lifespan in Harsh Environments

GaAs FETs exhibit superior resistance to radiation and high-temperature operation, making them highly reliable in harsh environments such as space and military applications. SiGe HBTs offer enhanced thermal stability and improved tolerance to electrostatic discharge, contributing to extended lifespan under fluctuating thermal and electrical stress conditions. Both technologies have optimized device architectures to mitigate degradation mechanisms like hot-electron effects and bias stress, but GaAs FETs generally outperform in extreme radiation hardness while SiGe HBTs excel in thermal cycling endurance.

Application Suitability: RF, Microwave, and Digital Circuits

GaAs FETs deliver superior performance in high-frequency RF and microwave applications due to their high electron mobility and low noise figure, making them ideal for wireless communication systems and radar. SiGe HBTs excel in integrating analog and digital circuits, offering high gain and speed suitable for mixed-signal and digital RF applications such as high-speed data converters and wireless base stations. Understanding your specific application needs helps determine whether GaAs FETs or SiGe HBTs provide the optimal balance of frequency performance, integration capability, and power efficiency.

Market Trends and Future Perspectives

GaAs FETs dominate high-frequency and microwave applications due to superior electron mobility and noise performance, driving growth in 5G infrastructure and satellite communications markets. SiGe HBTs gain traction in high-speed digital and mixed-signal ICs for automotive radar and mmWave 5G, benefiting from CMOS compatibility and cost-efficiency. Ongoing advancements in integration and power efficiency signal robust future demand for both technologies across expanding wireless and defense sectors.

GaAs FET vs SiGe HBT Infographic

electrown.com

electrown.com