Microstrip and stripline are two common types of transmission lines used in high-frequency circuit design, with microstrip placed on the surface of the PCB and stripline embedded between dielectric layers, affecting signal integrity and electromagnetic interference differently. Understanding the advantages and limitations of each can help you choose the best solution for your specific circuit requirements; explore the rest of this article to learn more about their differences and applications.

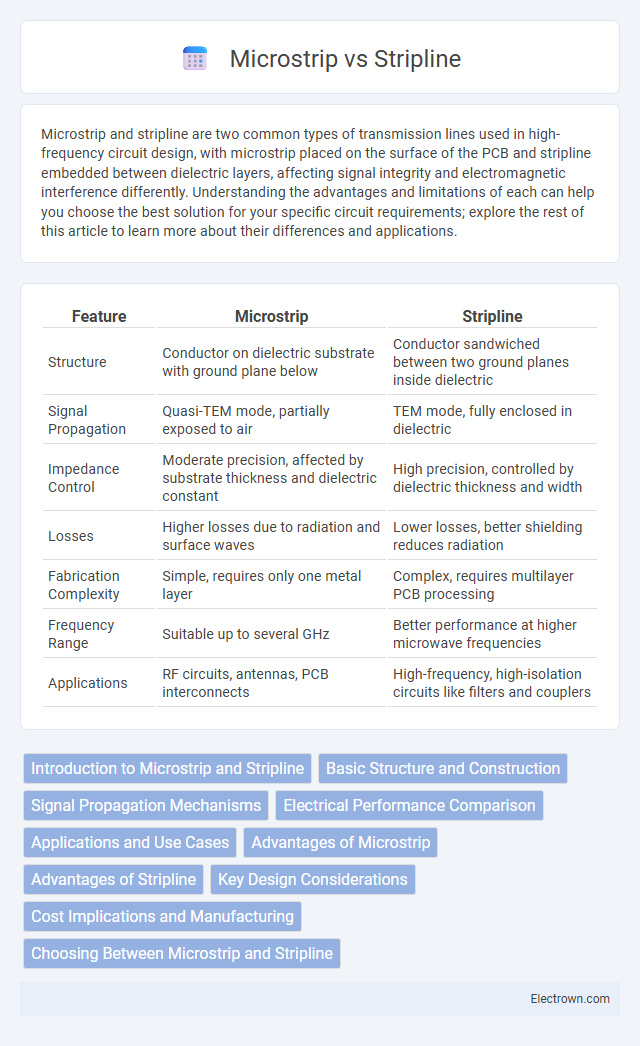

Table of Comparison

| Feature | Microstrip | Stripline |

|---|---|---|

| Structure | Conductor on dielectric substrate with ground plane below | Conductor sandwiched between two ground planes inside dielectric |

| Signal Propagation | Quasi-TEM mode, partially exposed to air | TEM mode, fully enclosed in dielectric |

| Impedance Control | Moderate precision, affected by substrate thickness and dielectric constant | High precision, controlled by dielectric thickness and width |

| Losses | Higher losses due to radiation and surface waves | Lower losses, better shielding reduces radiation |

| Fabrication Complexity | Simple, requires only one metal layer | Complex, requires multilayer PCB processing |

| Frequency Range | Suitable up to several GHz | Better performance at higher microwave frequencies |

| Applications | RF circuits, antennas, PCB interconnects | High-frequency, high-isolation circuits like filters and couplers |

Introduction to Microstrip and Stripline

Microstrip and Stripline are two fundamental types of transmission lines used in high-frequency circuit design, each offering distinct structural and performance characteristics. Microstrip consists of a conductive strip separated from a ground plane by a dielectric layer, providing easy access for component mounting and testing. Stripline, on the other hand, sandwiches the conductive strip between two ground planes, resulting in improved signal shielding and reduced electromagnetic interference, which can enhance the integrity of your high-frequency signals.

Basic Structure and Construction

Microstrip consists of a conductive strip separated from a ground plane by a dielectric substrate, with the signal line exposed to air on one side, enabling easier fabrication and inspection. Stripline features a conductive strip embedded between two ground planes within a homogeneous dielectric medium, providing better isolation and symmetric electromagnetic fields. Your choice between microstrip and stripline depends on the desired impedance control, signal integrity, and manufacturing constraints.

Signal Propagation Mechanisms

Microstrip and stripline are both transmission line structures used in high-frequency circuits, with distinct signal propagation mechanisms affecting their performance. Microstrip signals propagate primarily along the dielectric interface between the conductor and the air, resulting in partially unshielded electromagnetic fields and higher radiation losses. Stripline confines the signal completely within a homogeneous dielectric material between two ground planes, providing better shielding, lower crosstalk, and more consistent impedance, which benefits your high-frequency signal integrity.

Electrical Performance Comparison

Microstrip exhibits higher radiation loss and surface wave excitation compared to stripline, impacting signal integrity at high frequencies. Stripline offers superior electromagnetic shielding and lower crosstalk due to its enclosed dielectric structure, enhancing noise immunity. Understanding these electrical performance differences helps optimize your PCB design for either signal fidelity or cost-effectiveness.

Applications and Use Cases

Microstrip is widely used in wireless communication devices, radar systems, and satellite equipment due to its ease of fabrication and accessibility for surface mounting. Stripline finds applications in high-speed digital circuits, RF filters, and connectors where superior signal integrity and reduced electromagnetic interference are critical. Both technologies serve essential roles in microwave and RF engineering, with microstrip favored for cost-effective, compact designs and stripline preferred in environments demanding rigorous noise isolation.

Advantages of Microstrip

Microstrip offers easier fabrication and testing compared to stripline due to its single-layer structure and accessibility from the top side. The reduced manufacturing cost and simplified integration with surface-mount components make microstrip ideal for compact and cost-sensitive RF circuits. You benefit from greater design flexibility and straightforward impedance control, enhancing overall performance in wireless communication systems.

Advantages of Stripline

Stripline offers superior electromagnetic shielding compared to microstrip, resulting in reduced signal interference and crosstalk, which enhances signal integrity in high-frequency circuits. Its fully enclosed design supports better controlled impedance and consistent transmission line characteristics, making it ideal for sensitive RF and microwave applications. Your PCB designs benefit from stripline's ability to minimize radiation losses and support multilayer stack-ups for compact, high-performance layouts.

Key Design Considerations

Microstrip and stripline differ in electromagnetic field confinement, affecting signal integrity and crosstalk in high-frequency circuits. Microstrip's ease of fabrication suits flexible designs where surface mounting is required, while stripline offers superior shielding and reduced interference due to its embedded conductor layer. Your choice depends on factors like impedance control, dielectric constant, and manufacturing complexity to optimize performance in RF and microwave applications.

Cost Implications and Manufacturing

Microstrip circuits generally offer lower manufacturing costs due to simpler fabrication processes and fewer material layers compared to stripline structures, which require precise alignment and additional dielectric layers. The cost efficiency of microstrip makes it favorable for high-volume production and prototyping, while stripline's complexity and superior electromagnetic shielding often justify its higher expense in critical applications. Choosing between microstrip and stripline involves balancing budget constraints with performance requirements and production capabilities.

Choosing Between Microstrip and Stripline

Choosing between microstrip and stripline depends on your design's requirements for signal integrity, electromagnetic interference (EMI) shielding, and manufacturing complexity. Microstrip offers easier fabrication and visual inspection, suitable for less critical high-frequency signals, while stripline provides superior EMI suppression and controlled impedance, ideal for sensitive RF or microwave circuits. Evaluating your application's frequency range, environmental conditions, and cost constraints will help determine the optimal transmission line technology.

Microstrip vs Stripline Infographic

electrown.com

electrown.com