Planar resonators offer compact size and ease of integration with printed circuit boards, making them ideal for high-frequency applications, while lumped resonators, composed of discrete inductors and capacitors, provide design flexibility and are preferable for low-frequency circuits. To understand how each resonator can enhance Your specific circuit design and application, explore the full article for detailed comparisons and practical insights.

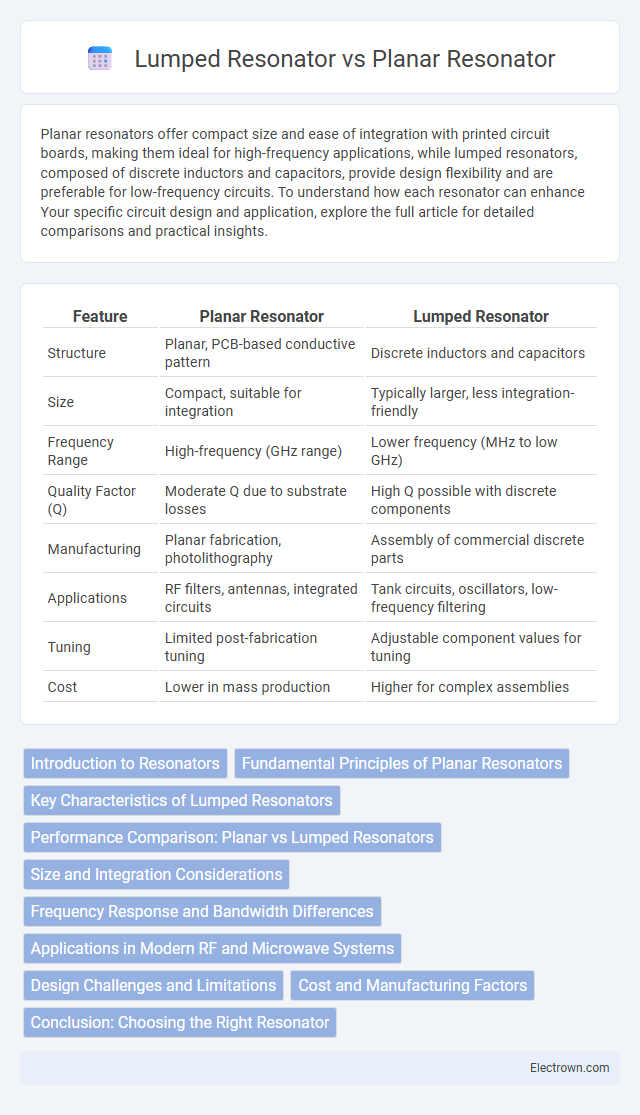

Table of Comparison

| Feature | Planar Resonator | Lumped Resonator |

|---|---|---|

| Structure | Planar, PCB-based conductive pattern | Discrete inductors and capacitors |

| Size | Compact, suitable for integration | Typically larger, less integration-friendly |

| Frequency Range | High-frequency (GHz range) | Lower frequency (MHz to low GHz) |

| Quality Factor (Q) | Moderate Q due to substrate losses | High Q possible with discrete components |

| Manufacturing | Planar fabrication, photolithography | Assembly of commercial discrete parts |

| Applications | RF filters, antennas, integrated circuits | Tank circuits, oscillators, low-frequency filtering |

| Tuning | Limited post-fabrication tuning | Adjustable component values for tuning |

| Cost | Lower in mass production | Higher for complex assemblies |

Introduction to Resonators

Planar resonators, characterized by their compact, flat structures fabricated on substrates using microstrip or stripline technologies, offer high quality factors and integration with microwave circuits, making them ideal for modern RF applications. Lumped resonators, consisting of discrete inductors and capacitors, provide simple, easily tunable resonant circuits with lower frequencies, commonly used in filters and oscillators. Both resonator types are fundamental in frequency selection and signal processing within communication systems, but their design choices impact size, performance, and integration complexity.

Fundamental Principles of Planar Resonators

Planar resonators operate based on distributed electromagnetic fields confined within a planar structure, typically microstrip or stripline configurations, allowing resonance at specific microwave frequencies through geometric dimensions and substrate properties. Unlike lumped resonators that rely on discrete inductors and capacitors, planar resonators utilize the physical length and width of the transmission line to achieve resonance, which results in lower parasitic losses and better integration in microwave circuits. Key parameters such as effective dielectric constant and conductor geometry dictate the resonant frequency and quality factor, optimizing performance for filters and oscillators in RF and microwave applications.

Key Characteristics of Lumped Resonators

Lumped resonators are characterized by discrete circuit elements such as inductors and capacitors, enabling compact design suitable for low-frequency applications. They offer precise resonance frequency control and easy integration into printed circuit boards (PCBs) due to their well-defined lumped parameters. These resonators typically exhibit lower quality factors compared to planar resonators but provide enhanced tunability and flexibility in compact RF and microwave circuits.

Performance Comparison: Planar vs Lumped Resonators

Planar resonators typically offer higher quality factors (Q-factors) and better frequency stability than lumped resonators due to their distributed element design, which reduces parasitic losses. Lumped resonators, while more compact and easier to integrate in low-frequency applications, often suffer from lower Q-factors and limited power handling capabilities. Consequently, planar resonators are preferred in high-frequency, high-performance RF circuits where enhanced signal integrity and reduced insertion loss are critical.

Size and Integration Considerations

Planar resonators offer compact size and superior integration capabilities on printed circuit boards or semiconductor substrates, making them ideal for miniaturized RF and microwave circuits. Lumped resonators, although potentially smaller at lower frequencies, become impractical for high-frequency applications due to parasitic effects and limited scalability in integrated circuits. The planar design supports easier mass production and compatibility with microfabrication processes, enhancing system-level integration efficiency.

Frequency Response and Bandwidth Differences

Planar resonators typically exhibit narrower bandwidths and higher frequency selectivity compared to lumped resonators, making them ideal for applications requiring sharp frequency response. Lumped resonators offer broader bandwidths due to their discrete circuit elements, allowing greater frequency tunability but with reduced selectivity. Your choice depends on whether you prioritize precise frequency control in planar designs or wider operational bandwidth using lumped components.

Applications in Modern RF and Microwave Systems

Planar resonators offer compact size and easy integration, making them ideal for modern RF and microwave applications such as filters, oscillators, and antennas in wireless communication devices. Lumped resonators provide precise frequency control and are commonly used in low-frequency circuits and miniaturized components for IoT devices and portable electronics. Your choice depends on the specific application requirements, including frequency range, size constraints, and performance demands.

Design Challenges and Limitations

Planar resonators face design challenges such as substrate losses, limited quality factor (Q), and radiation losses that restrict their efficiency at high frequencies. Lumped resonators offer compact size and easier integration but suffer from parasitic capacitance and inductance, which can degrade performance and limit the operating frequency range. Your choice depends on balancing frequency requirements, size constraints, and acceptable loss levels inherent to each resonator type.

Cost and Manufacturing Factors

Planar resonators generally offer lower manufacturing costs due to their simpler fabrication processes compatible with standard PCB techniques, enabling mass production and consistent quality. Lumped resonators often require discrete components and tighter tolerances, which can increase assembly complexity and cost. Your choice depends on balancing cost-efficiency with performance requirements in production volume and application specificity.

Conclusion: Choosing the Right Resonator

Planar resonators excel in compactness and integration for high-frequency applications, offering low loss and easy fabrication on printed circuit boards. Lumped resonators provide precise frequency control and are ideal for low-frequency circuits due to their discrete component nature and versatile tuning options. Selecting the right resonator depends on application frequency, size constraints, and required performance characteristics.

Planar Resonator vs Lumped Resonator Infographic

electrown.com

electrown.com