Thermoelectric coolers provide precise temperature control with no moving parts, making them ideal for compact electronics and silent operation, while forced air cooling relies on fans to dissipate heat efficiently but can generate noise and require more space. Explore the rest of the article to discover which cooling method best suits your specific application and performance needs.

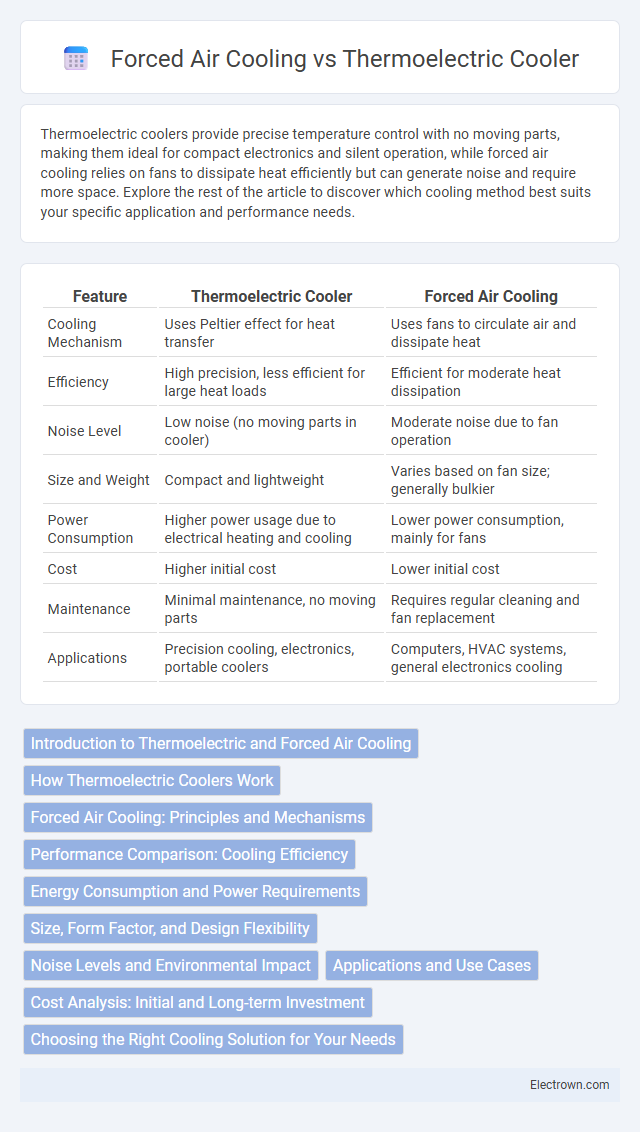

Table of Comparison

| Feature | Thermoelectric Cooler | Forced Air Cooling |

|---|---|---|

| Cooling Mechanism | Uses Peltier effect for heat transfer | Uses fans to circulate air and dissipate heat |

| Efficiency | High precision, less efficient for large heat loads | Efficient for moderate heat dissipation |

| Noise Level | Low noise (no moving parts in cooler) | Moderate noise due to fan operation |

| Size and Weight | Compact and lightweight | Varies based on fan size; generally bulkier |

| Power Consumption | Higher power usage due to electrical heating and cooling | Lower power consumption, mainly for fans |

| Cost | Higher initial cost | Lower initial cost |

| Maintenance | Minimal maintenance, no moving parts | Requires regular cleaning and fan replacement |

| Applications | Precision cooling, electronics, portable coolers | Computers, HVAC systems, general electronics cooling |

Introduction to Thermoelectric and Forced Air Cooling

Thermoelectric coolers use the Peltier effect to transfer heat across semiconductor materials, enabling precise temperature control in compact devices without moving parts. Forced air cooling relies on fans or blowers to dissipate heat by increasing airflow over components, making it effective for high-power electronics and systems with substantial heat generation. Your choice between thermoelectric and forced air cooling depends on factors like cooling efficiency, noise levels, size constraints, and energy consumption.

How Thermoelectric Coolers Work

Thermoelectric coolers (TECs) operate on the Peltier effect, where an electrical current passes through two different semiconductors, creating a temperature difference that transfers heat from one side to the other. Unlike forced air cooling, which relies on airflow to dissipate heat from components, TECs provide precise temperature control without moving parts, enabling efficient cooling in compact electronic devices. Your choice between these methods depends on factors like size constraints, noise tolerance, and the specific cooling requirements of your application.

Forced Air Cooling: Principles and Mechanisms

Forced air cooling operates by actively moving air across heat-generating components to dissipate thermal energy efficiently. It utilizes fans to enhance airflow velocity, increasing convective heat transfer rates and reducing the temperature of electronic devices or systems. Your choice of forced air cooling ensures consistent thermal management by maintaining optimal airflow patterns, preventing localized overheating.

Performance Comparison: Cooling Efficiency

Thermoelectric coolers offer precise temperature control and rapid cooling by exploiting the Peltier effect but generally have lower cooling efficiency compared to forced air cooling systems, which dissipate heat more effectively through airflow. Forced air cooling achieves higher thermal transfer rates and can handle larger heat loads with less energy consumption, making it more efficient for high-performance or industrial applications. Thermoelectric coolers are preferred for compact, low-noise environments despite their limited cooling capacity and higher power usage.

Energy Consumption and Power Requirements

Thermoelectric coolers generally consume more power due to their solid-state cooling technology, which relies on the Peltier effect and requires a continuous electric current to maintain temperature differences. Forced air cooling systems use fans to move air over heat sinks and are typically more energy-efficient, consuming less power for equivalent heat dissipation in consumer electronics and industrial applications. Power requirements for thermoelectric coolers increase proportionally with the cooling load, while forced air coolers maintain relatively stable and lower energy usage under similar conditions.

Size, Form Factor, and Design Flexibility

Thermoelectric coolers (TECs) offer compact size and versatile form factors, making them ideal for applications requiring small, integrated cooling solutions. Unlike forced air cooling, which depends on bulky fans and heat sinks, TECs can be designed into thin, flat modules, enhancing design flexibility in constrained spaces. TECs provide precise temperature control without moving parts, enabling quiet operation and innovative product designs where space and noise are critical factors.

Noise Levels and Environmental Impact

Thermoelectric coolers operate silently due to the absence of moving parts, making them ideal for noise-sensitive environments, whereas forced air cooling relies on fans that generate noticeable noise levels. Thermoelectric devices use solid-state Peltier elements, which reduce environmental impact by avoiding the use of refrigerants and minimizing energy consumption compared to traditional air cooling systems. Choosing a thermoelectric cooler can help you achieve quieter operation while contributing to a more eco-friendly cooling solution.

Applications and Use Cases

Thermoelectric coolers excel in precision temperature control for applications like electronics cooling, medical devices, and portable refrigeration where compact size and silent operation are critical. Forced air cooling is widely used in computer systems, industrial machinery, and HVAC units due to its efficiency in dissipating heat over large surfaces and maintaining airflow. Your choice depends on whether you need targeted cooling with no moving parts or broad, airflow-driven thermal management.

Cost Analysis: Initial and Long-term Investment

Thermoelectric coolers typically have higher initial costs due to their advanced Peltier technology, whereas forced air cooling systems are generally more affordable upfront with simpler components like fans and heat sinks. Over the long term, thermoelectric coolers demand less maintenance and offer energy efficiency benefits that can reduce operational expenses, while forced air systems may incur higher costs from frequent fan replacements and increased power consumption. Assessing your budget should include both upfront expenses and ongoing costs to determine which cooling solution delivers better value for your application.

Choosing the Right Cooling Solution for Your Needs

Thermoelectric coolers offer precise temperature control with compact, vibration-free operation, making them ideal for applications requiring localized cooling or silent environments. Forced air cooling is typically more cost-effective and efficient for general heat dissipation, using fans to rapidly remove heat from larger surfaces or components. Your choice depends on factors like noise tolerance, cooling precision, space constraints, and power consumption requirements.

Thermoelectric cooler vs forced air cooling Infographic

electrown.com

electrown.com