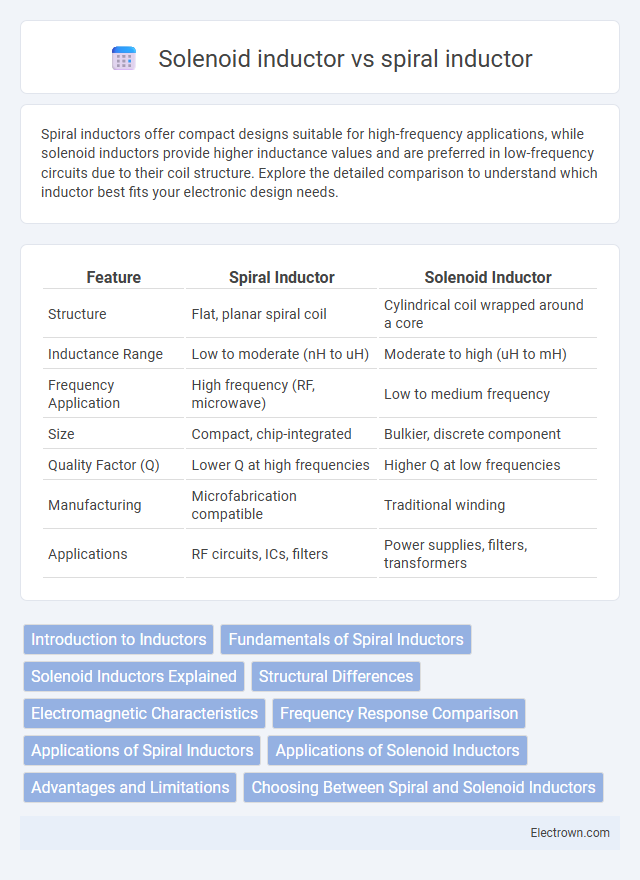

Spiral inductors offer compact designs suitable for high-frequency applications, while solenoid inductors provide higher inductance values and are preferred in low-frequency circuits due to their coil structure. Explore the detailed comparison to understand which inductor best fits your electronic design needs.

Table of Comparison

| Feature | Spiral Inductor | Solenoid Inductor |

|---|---|---|

| Structure | Flat, planar spiral coil | Cylindrical coil wrapped around a core |

| Inductance Range | Low to moderate (nH to uH) | Moderate to high (uH to mH) |

| Frequency Application | High frequency (RF, microwave) | Low to medium frequency |

| Size | Compact, chip-integrated | Bulkier, discrete component |

| Quality Factor (Q) | Lower Q at high frequencies | Higher Q at low frequencies |

| Manufacturing | Microfabrication compatible | Traditional winding |

| Applications | RF circuits, ICs, filters | Power supplies, filters, transformers |

Introduction to Inductors

Spiral inductors and solenoid inductors are essential components in electronic circuits used for energy storage in magnetic fields. Spiral inductors feature planar coil designs ideal for high-frequency applications due to their low parasitic capacitance and compact form factor. Solenoid inductors consist of wire coils wound around a cylindrical core, offering higher inductance values and better magnetic coupling for low-frequency and power applications.

Fundamentals of Spiral Inductors

Spiral inductors are planar components fabricated on semiconductor substrates, utilizing a winding pattern that forms a flat, spiral geometry to generate inductance through magnetic flux linkage. Key factors influencing their performance include the number of turns, spacing between turns, metal thickness, and substrate characteristics which affect parasitic capacitance and quality factor. Your circuit design benefits from spiral inductors when compact, high-frequency inductance is required, differing from solenoid inductors that rely on three-dimensional coils and are more suitable for lower-frequency or higher current applications.

Solenoid Inductors Explained

Solenoid inductors consist of wire coils wrapped around a cylindrical core, offering high inductance and strong magnetic fields in a compact form, ideal for EMI filtering and RF applications. Compared to spiral inductors, solenoids provide greater inductance values due to their 3D coil structure, enabling enhanced energy storage and efficiency in power supplies and inductive sensors. Their design allows for better magnetic flux confinement, reducing losses and improving performance in high-current circuits.

Structural Differences

Spiral inductors are planar components etched on a circuit board, characterized by their flat, coiled geometry, which allows for easy integration in IC designs and compact layouts. Solenoid inductors consist of wire wound around a cylindrical core, creating a three-dimensional coil that provides higher inductance and stronger magnetic fields compared to spiral inductors of similar size. Your choice depends on the structural constraints and required inductance values in your electronic application.

Electromagnetic Characteristics

Spiral inductors exhibit lower inductance and higher parasitic capacitance compared to solenoid inductors, making them more suitable for high-frequency applications. Solenoid inductors generate a stronger magnetic field with higher inductance due to their 3D coil structure, enhancing energy storage in low-frequency circuits. Your choice depends on the electromagnetic characteristics required, with spirals favoring compactness and frequency stability, while solenoids offer higher inductance and magnetic coupling.

Frequency Response Comparison

Spiral inductors generally perform better at higher frequencies due to their planar design, which minimizes parasitic capacitance and resistive losses. Solenoid inductors offer higher inductance values but tend to suffer from lower self-resonant frequencies, limiting their effectiveness in high-frequency applications. When selecting an inductor for your circuit, consider spiral inductors for RF and microwave frequencies, while solenoids are more suitable for low-frequency power applications.

Applications of Spiral Inductors

Spiral inductors are widely used in high-frequency circuits such as RF integrated circuits, voltage-controlled oscillators (VCOs), and chip-scale inductors due to their compact size and ease of integration on semiconductor substrates. Unlike solenoid inductors, which are common in power applications and lower-frequency circuits, spiral inductors excel in microwave frequency ranges and on-chip passive components. Your choice of spiral inductors enables miniaturized designs and improved performance in wireless communication devices and portable electronics.

Applications of Solenoid Inductors

Solenoid inductors are widely used in applications requiring strong magnetic fields and high inductance, such as in transformers, electromagnets, and relay coils. Their cylindrical coil design allows for efficient energy storage in power supplies, RF circuits, and inductive sensors. You'll often find solenoid inductors in devices where space is less constrained and high inductance values are essential.

Advantages and Limitations

Spiral inductors offer compact size and ease of integration into monolithic microwave integrated circuits (MMICs), making them ideal for high-frequency applications such as RF and microwave circuits. Solenoid inductors provide higher inductance values and better magnetic coupling, which is advantageous for low-frequency power applications but come with larger physical dimensions and increased parasitic effects. Your choice depends on the operating frequency and space constraints, balancing between the spiral inductor's miniaturization benefits and the solenoid's superior inductance performance.

Choosing Between Spiral and Solenoid Inductors

Choosing between spiral and solenoid inductors depends on your application's frequency, size constraints, and inductance requirements. Spiral inductors offer compact layouts with low parasitic capacitance, making them ideal for high-frequency integrated circuits. Solenoid inductors provide higher inductance values and better magnetic coupling, suitable for power applications where space allows larger components.

Spiral inductor vs solenoid inductor Infographic

electrown.com

electrown.com