pHEMT (Pseudomorphic High Electron Mobility Transistor) and mHEMT (Metamorphic High Electron Mobility Transistor) differ mainly in their substrate and channel material, affecting performance in high-frequency applications. Understanding these distinctions can enhance your choice for specific RF or microwave designs; explore the rest of the article to learn how each technology impacts your system.

Table of Comparison

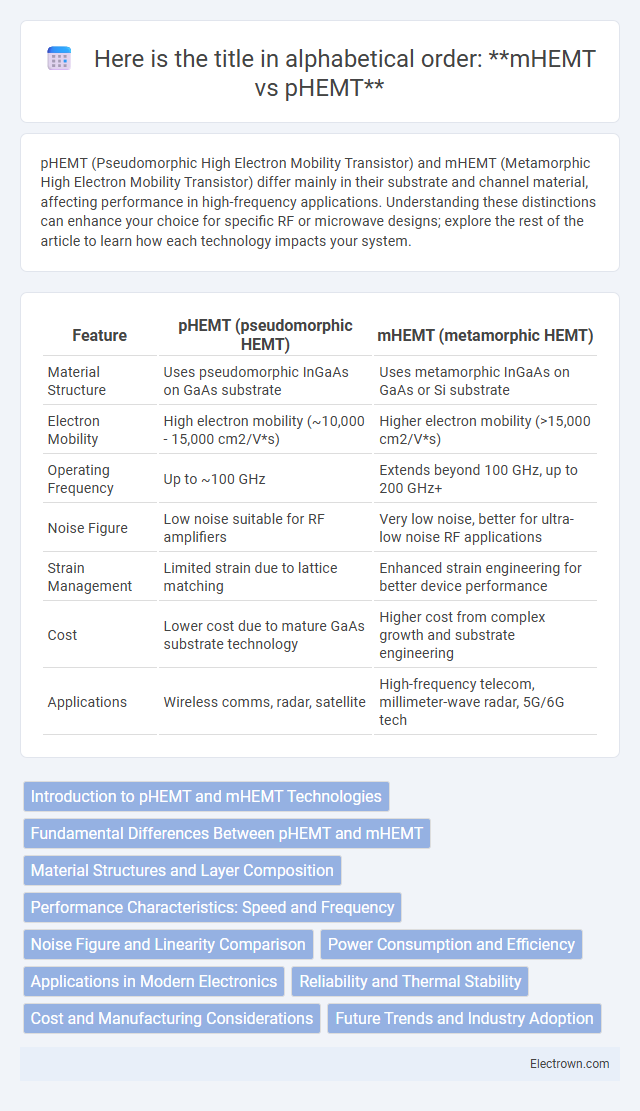

| Feature | pHEMT (pseudomorphic HEMT) | mHEMT (metamorphic HEMT) |

|---|---|---|

| Material Structure | Uses pseudomorphic InGaAs on GaAs substrate | Uses metamorphic InGaAs on GaAs or Si substrate |

| Electron Mobility | High electron mobility (~10,000 - 15,000 cm2/V*s) | Higher electron mobility (>15,000 cm2/V*s) |

| Operating Frequency | Up to ~100 GHz | Extends beyond 100 GHz, up to 200 GHz+ |

| Noise Figure | Low noise suitable for RF amplifiers | Very low noise, better for ultra-low noise RF applications |

| Strain Management | Limited strain due to lattice matching | Enhanced strain engineering for better device performance |

| Cost | Lower cost due to mature GaAs substrate technology | Higher cost from complex growth and substrate engineering |

| Applications | Wireless comms, radar, satellite | High-frequency telecom, millimeter-wave radar, 5G/6G tech |

Introduction to pHEMT and mHEMT Technologies

pHEMT (pseudomorphic High Electron Mobility Transistor) technology utilizes a strained semiconductor layer to achieve high electron mobility and enhanced frequency performance, making it ideal for high-frequency RF applications. mHEMT (metamorphic High Electron Mobility Transistor) technology employs a metamorphic buffer layer, allowing the integration of lattice-mismatched materials to extend device operation into higher frequency ranges and improve breakdown voltage. Both pHEMT and mHEMT technologies are critical for advanced telecommunications and radar systems, with mHEMTs offering greater flexibility in substrate choice and enhanced power-handling capabilities.

Fundamental Differences Between pHEMT and mHEMT

pHEMT (pseudomorphic High Electron Mobility Transistor) utilizes a strained layer of InGaAs on GaAs substrate to enhance electron mobility by creating a two-dimensional electron gas, while mHEMT (metamorphic High Electron Mobility Transistor) employs a metamorphic buffer layer to integrate higher indium content InGaAs on a GaAs substrate for improved electron velocity and reduced parasitic capacitance. The fundamental difference lies in the substrate and channel engineering, where pHEMT uses a lattice-matched pseudomorphic layer and mHEMT incorporates a metamorphic buffer to enable wider bandgap material integration. Your choice between pHEMT and mHEMT depends on the specific application requirements for frequency, noise performance, and thermal management.

Material Structures and Layer Composition

pHEMTs utilize a pseudomorphic GaAs/InGaAs heterojunction that forms a high-electron-mobility channel, combining a strained InGaAs layer on a GaAs substrate to enhance electron mobility while maintaining lattice matching. mHEMTs employ metamorphic buffers allowing for a relaxed InP or InGaAs layer on GaAs substrates, enabling the integration of higher indium content channels with improved electron velocity and reduced parasitic capacitance. The key difference lies in the buffer design: pHEMTs rely on thin pseudomorphic layers for performance, whereas mHEMTs use thicker metamorphic buffer layers to achieve superior mobility and scaling potential.

Performance Characteristics: Speed and Frequency

pHEMT devices offer high electron mobility and are well-known for their excellent speed and frequency response, typically operating efficiently up to around 40 GHz. mHEMTs, which integrate metamorphic buffer layers, achieve even higher cutoff frequencies exceeding 60 GHz, enabling superior performance in millimeter-wave and high-speed communication applications. The enhanced electron mobility and reduced parasitic capacitance in mHEMTs contribute significantly to their faster switching speeds and greater frequency handling capabilities compared to conventional pHEMTs.

Noise Figure and Linearity Comparison

pHEMT devices generally provide a lower noise figure, making them ideal for applications requiring ultra-low noise amplification, such as radar and satellite communications. mHEMTs, however, offer superior linearity and power handling, which is crucial for high-frequency wireless communication systems where signal distortion must be minimized. Your choice between pHEMT and mHEMT should balance the need for noise performance against linearity requirements to optimize overall system efficiency.

Power Consumption and Efficiency

mHEMTs offer significantly lower power consumption compared to pHEMTs due to their advanced material composition and improved electron mobility, resulting in higher efficiency in high-frequency applications. Your choice between pHEMT and mHEMT should consider that mHEMT devices provide better thermal performance and reduced energy loss, which enhances overall system longevity and reduces operational costs. Power efficiency gains with mHEMT technology make it ideal for next-generation communications and radar systems demanding minimal energy use without sacrificing performance.

Applications in Modern Electronics

pHEMTs excel in high-frequency applications such as satellite communications and radar systems due to their low noise figure and high gain, making them ideal for RF front-end components. mHEMTs outperform pHEMTs in millimeter-wave frequencies above 100 GHz, enabling advanced 5G networks and terahertz imaging systems with superior electron mobility and thermal stability. Both transistor types are integral in modern electronics, with pHEMTs dominating lower GHz ranges and mHEMTs pushing the boundaries of ultrahigh-frequency performance.

Reliability and Thermal Stability

pHEMTs exhibit high reliability and moderate thermal stability, making them suitable for applications with less extreme temperature variations. mHEMTs offer enhanced thermal stability and greater reliability due to improved material interfaces and reduced lattice mismatch, which ensures consistent performance in high-temperature environments. Your choice between pHEMT and mHEMT should consider the thermal conditions and long-term operational reliability required for your specific application.

Cost and Manufacturing Considerations

pHEMT devices generally offer lower manufacturing costs due to simpler epitaxial structures and well-established fabrication processes, making them a cost-effective choice for high-frequency applications. mHEMTs, incorporating metamorphic buffer layers, involve more complex and time-consuming growth techniques, which increase production expenses and yield challenges. Your selection between pHEMT and mHEMT should weigh these cost factors against performance requirements in specific semiconductor applications.

Future Trends and Industry Adoption

mHEMT technology demonstrates superior high-frequency performance and energy efficiency compared to pHEMT, driving exponential growth in applications such as 5G, satellite communications, and radar systems. The semiconductor industry increasingly prioritizes mHEMT for its enhanced electron mobility and reduced noise figures, enabling next-generation wireless infrastructure with higher bandwidth and lower power consumption. Market projections indicate mHEMT adoption will outpace pHEMT as manufacturers focus on scalable, cost-efficient production methods to meet escalating demands for advanced RF and microwave components.

pHEMT vs mHEMT Infographic

electrown.com

electrown.com