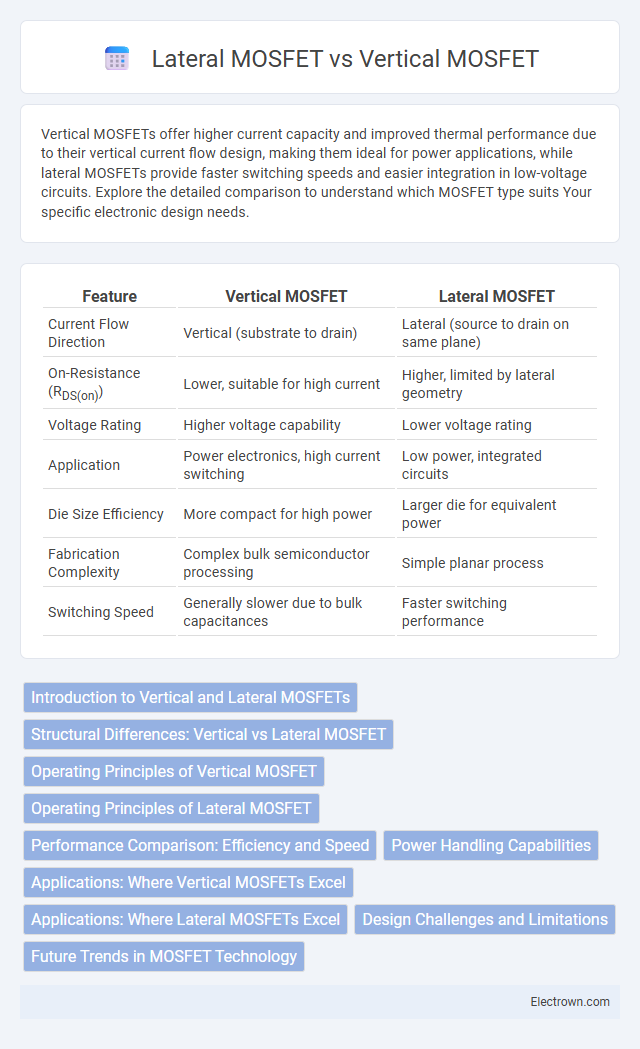

Vertical MOSFETs offer higher current capacity and improved thermal performance due to their vertical current flow design, making them ideal for power applications, while lateral MOSFETs provide faster switching speeds and easier integration in low-voltage circuits. Explore the detailed comparison to understand which MOSFET type suits Your specific electronic design needs.

Table of Comparison

| Feature | Vertical MOSFET | Lateral MOSFET |

|---|---|---|

| Current Flow Direction | Vertical (substrate to drain) | Lateral (source to drain on same plane) |

| On-Resistance (RDS(on)) | Lower, suitable for high current | Higher, limited by lateral geometry |

| Voltage Rating | Higher voltage capability | Lower voltage rating |

| Application | Power electronics, high current switching | Low power, integrated circuits |

| Die Size Efficiency | More compact for high power | Larger die for equivalent power |

| Fabrication Complexity | Complex bulk semiconductor processing | Simple planar process |

| Switching Speed | Generally slower due to bulk capacitances | Faster switching performance |

Introduction to Vertical and Lateral MOSFETs

Vertical MOSFETs feature a current flow perpendicular to the wafer surface, enabling higher current densities and improved efficiency in power applications. Lateral MOSFETs conduct current parallel to the wafer surface, offering simpler integration in low-voltage, high-frequency circuits. Understanding these architectures helps optimize your device selection for specific electrical performance and reliability requirements.

Structural Differences: Vertical vs Lateral MOSFET

Vertical MOSFETs feature a layered structure where current flows vertically from source to drain across the wafer thickness, enabling higher current densities and better heat dissipation. Lateral MOSFETs have current flowing horizontally on the wafer surface, simplifying integration with other components but limiting current capacity and increasing on-resistance. Your choice between vertical and lateral MOSFETs impacts device performance, thermal management, and integration flexibility based on the structural differences.

Operating Principles of Vertical MOSFET

Vertical MOSFETs operate by allowing current to flow vertically from the source at the top through the channel to the drain at the bottom, utilizing the bulk semiconductor substrate as the conduction path. This design leverages a vertical channel along the depth of the substrate, enabling higher current density and improved on-resistance compared to lateral MOSFETs. The vertical structure also supports efficient heat dissipation and scalability for high-power applications in power electronics.

Operating Principles of Lateral MOSFET

Lateral MOSFETs operate with current flowing parallel to the wafer surface, where the source, drain, and gate are arranged side-by-side on the same plane. The lateral structure enables easier integration with other planar devices in CMOS processes, making it ideal for logic circuits. This design provides lower gate-to-drain capacitance and faster switching speeds, but typically supports lower current densities compared to vertical MOSFETs.

Performance Comparison: Efficiency and Speed

Vertical MOSFETs demonstrate superior efficiency and higher current capacity due to their vertical current flow, enabling better heat dissipation and reduced on-resistance compared to Lateral MOSFETs. Lateral MOSFETs typically offer faster switching speeds because of their lower gate charge, making them ideal for high-frequency applications. Your choice between the two should balance the need for efficiency and power handling (favoring Vertical MOSFETs) against the requirement for speed and switching performance (favoring Lateral MOSFETs).

Power Handling Capabilities

Vertical MOSFETs exhibit superior power handling capabilities due to their current flow perpendicular to the wafer surface, enabling lower on-resistance and higher current density. Lateral MOSFETs, with current flowing parallel to the surface, typically face limitations in voltage and current handling because of longer conduction paths and higher resistance. These structural differences make Vertical MOSFETs preferable for high-power applications such as power converters and motor drives.

Applications: Where Vertical MOSFETs Excel

Vertical MOSFETs excel in high-power applications such as power supplies, motor drives, and DC-DC converters due to their low on-resistance and superior current handling capabilities. Their vertical structure allows for efficient heat dissipation and compact size, making them ideal for high-current and high-voltage environments. Your design benefits from enhanced efficiency and reliability when choosing Vertical MOSFETs for demanding power management tasks.

Applications: Where Lateral MOSFETs Excel

Lateral MOSFETs excel in analog and RF applications due to their low noise characteristics and better linearity, making them ideal for integrated circuits in communication devices. Their planar structure allows easy integration with other components on a single chip, enhancing performance in low-voltage, high-frequency environments. Common uses include voltage regulators, sensors, and signal processing circuits where efficient switching and minimal interference are critical.

Design Challenges and Limitations

Vertical MOSFETs face design challenges related to complex fabrication processes, such as precise epitaxial layer growth and intricate doping profiles, which can increase manufacturing costs and affect yield. Their vertical structure limits scalability in lateral device layouts but offers superior current density and breakdown voltage, critical for power applications. Lateral MOSFETs encounter limitations in achieving high breakdown voltages and on-resistance simultaneously due to planar design constraints, restricting their efficiency in high-power or high-voltage scenarios.

Future Trends in MOSFET Technology

Future trends in MOSFET technology emphasize the shift towards vertical MOSFETs due to their superior current density and enhanced thermal performance compared to lateral MOSFETs. Vertical MOSFETs enable higher voltage handling and reduced on-resistance, making them ideal for power electronics in electric vehicles and renewable energy systems. Your choice of MOSFET type will increasingly impact device efficiency and miniaturization as semiconductor technology advances.

Vertical MOSFET vs Lateral MOSFET Infographic

electrown.com

electrown.com