Isolation amplifiers provide galvanic separation to protect sensitive electronics from high voltages and noise, while instrumentation amplifiers focus on precise, low-level signal amplification with high input impedance and common-mode rejection. Understanding the differences can help you choose the right amplifier for your specific application--continue reading to explore their key features and use cases.

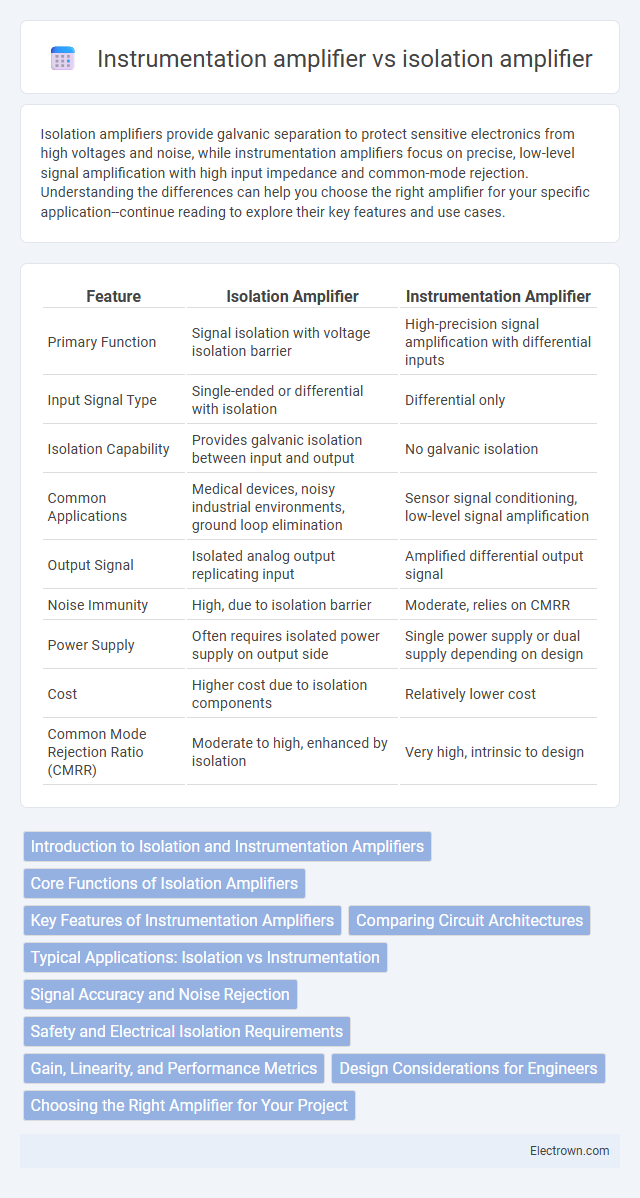

Table of Comparison

| Feature | Isolation Amplifier | Instrumentation Amplifier |

|---|---|---|

| Primary Function | Signal isolation with voltage isolation barrier | High-precision signal amplification with differential inputs |

| Input Signal Type | Single-ended or differential with isolation | Differential only |

| Isolation Capability | Provides galvanic isolation between input and output | No galvanic isolation |

| Common Applications | Medical devices, noisy industrial environments, ground loop elimination | Sensor signal conditioning, low-level signal amplification |

| Output Signal | Isolated analog output replicating input | Amplified differential output signal |

| Noise Immunity | High, due to isolation barrier | Moderate, relies on CMRR |

| Power Supply | Often requires isolated power supply on output side | Single power supply or dual supply depending on design |

| Cost | Higher cost due to isolation components | Relatively lower cost |

| Common Mode Rejection Ratio (CMRR) | Moderate to high, enhanced by isolation | Very high, intrinsic to design |

Introduction to Isolation and Instrumentation Amplifiers

Isolation amplifiers provide electrical isolation between input and output, protecting your system from high voltages and noise interference, making them ideal for medical, industrial, and measurement applications. Instrumentation amplifiers offer precise, stable gain with high input impedance and excellent common-mode rejection, specifically designed to amplify low-level differential signals accurately. Both amplifiers enhance signal integrity but serve distinct purposes based on isolation needs and signal conditions.

Core Functions of Isolation Amplifiers

Isolation amplifiers provide galvanic isolation between input and output signals, protecting sensitive equipment by eliminating ground loops and reducing noise interference. They are designed to safely transfer analog signals across different voltage potentials by using transformers, optical, or capacitive coupling. Unlike instrumentation amplifiers, which primarily amplify differential signals while rejecting common-mode noise, isolation amplifiers emphasize signal integrity and safety in hazardous or high-voltage environments.

Key Features of Instrumentation Amplifiers

Instrumentation amplifiers feature high input impedance, low output impedance, and excellent common-mode rejection ratio (CMRR), ensuring precise amplification of low-level differential signals in noisy environments. They offer adjustable gain through external resistors, allowing customization for various medical, industrial, and sensor applications. Your choice of an instrumentation amplifier ensures accurate, stable signal conditioning critical for data acquisition and measurement tasks.

Comparing Circuit Architectures

Isolation amplifiers use optocouplers, transformers, or capacitive coupling to provide galvanic isolation between input and output stages, enabling noise reduction and safety in high-voltage environments. Instrumentation amplifiers utilize a differential amplifier configuration with precision resistors and multiple op-amps to achieve high input impedance, low offset, and accurate gain for precise low-level signal acquisition. While isolation amplifiers emphasize electrical isolation and signal integrity across isolating barriers, instrumentation amplifiers prioritize precise differential signal amplification in low-noise, low-offset applications.

Typical Applications: Isolation vs Instrumentation

Isolation amplifiers are typically used in medical equipment, industrial process control, and measurement systems where electrical isolation is critical to protect users and sensitive circuits from high voltages or noise. Instrumentation amplifiers excel in applications requiring precise, low-level signal amplification with high input impedance, such as strain gauge measurements, sensor signal conditioning, and data acquisition systems. Your choice depends on whether patient safety and signal isolation or accurate signal amplification in noisy environments is the primary requirement.

Signal Accuracy and Noise Rejection

Isolation amplifiers provide superior noise rejection by electrically isolating the input from the output, effectively eliminating ground loop interference and common-mode noise. Instrumentation amplifiers excel in signal accuracy through high input impedance and precise gain settings, ensuring minimal signal distortion and excellent common-mode rejection ratio (CMRR). For applications demanding both high signal fidelity and robust noise immunity, the choice depends on whether isolation from high-voltage or ground noise is critical versus achieving ultra-precise gain and linearity.

Safety and Electrical Isolation Requirements

Isolation amplifiers provide galvanic isolation, protecting Your equipment and personnel from high voltage surges and ground loops by decoupling input and output signals. Instrumentation amplifiers, while offering high precision and low noise amplification, lack inherent electrical isolation, making them less suitable for critical safety environments. Choosing an isolation amplifier is essential when meeting stringent safety and electrical isolation requirements in industrial and medical applications.

Gain, Linearity, and Performance Metrics

An isolation amplifier provides galvanic isolation while maintaining signal integrity, making it suitable for high-voltage environments, with moderate gain accuracy and low non-linearity typically below 0.01%. Instrumentation amplifiers excel in gain precision, often offering gains adjustable up to 1000 with high linearity and low offset voltage, ideal for sensitive signal measurements. Your choice depends on performance metrics such as common-mode rejection ratio (CMRR), input impedance, and noise level, where instrumentation amplifiers generally deliver superior gain linearity and noise performance but lack isolation capabilities.

Design Considerations for Engineers

Isolation amplifiers require careful attention to galvanic isolation, noise immunity, and high common-mode voltage rejection, ensuring signal integrity in harsh environments. Instrumentation amplifiers emphasize precision, low offset voltage, high input impedance, and excellent gain accuracy for accurate differential signal amplification. Designers must evaluate your application's voltage levels, safety standards, and measurement accuracy to select the appropriate amplifier type.

Choosing the Right Amplifier for Your Project

Choosing the right amplifier depends on your project's requirements for signal integrity and safety; isolation amplifiers excel in breaking ground loops and providing galvanic isolation, ideal for high-voltage or noisy environments. Instrumentation amplifiers offer high input impedance, precision, and low noise, making them suitable for accurate low-level signal amplification in biomedical or sensor applications. Evaluate factors such as common-mode voltage, noise rejection, and isolation needs to determine the optimal amplifier type for your specific signal conditioning task.

Isolation amplifier vs instrumentation amplifier Infographic

electrown.com

electrown.com