A magneto generates electrical current through permanent magnets and rotating coils, making it ideal for ignition systems in small engines without requiring a battery, while an alternator produces electricity using electromagnets and is commonly found in vehicles to charge the battery and power electrical systems. Discover how understanding the key differences between a magneto and an alternator can enhance your knowledge of engine performance and electrical efficiency by reading the full article.

Table of Comparison

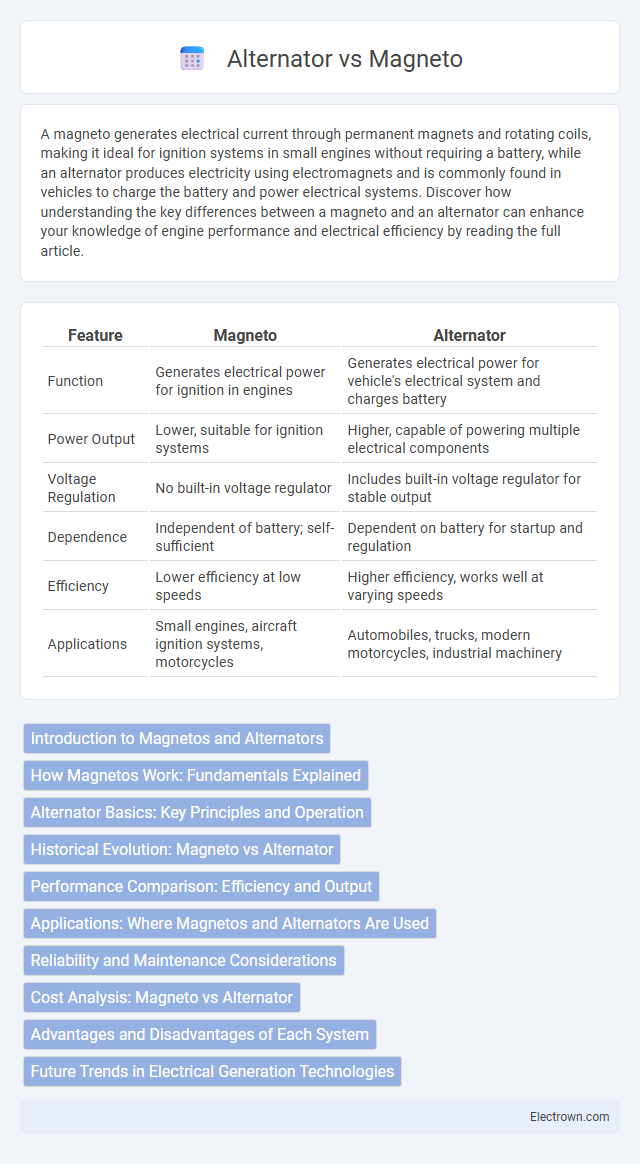

| Feature | Magneto | Alternator |

|---|---|---|

| Function | Generates electrical power for ignition in engines | Generates electrical power for vehicle's electrical system and charges battery |

| Power Output | Lower, suitable for ignition systems | Higher, capable of powering multiple electrical components |

| Voltage Regulation | No built-in voltage regulator | Includes built-in voltage regulator for stable output |

| Dependence | Independent of battery; self-sufficient | Dependent on battery for startup and regulation |

| Efficiency | Lower efficiency at low speeds | Higher efficiency, works well at varying speeds |

| Applications | Small engines, aircraft ignition systems, motorcycles | Automobiles, trucks, modern motorcycles, industrial machinery |

Introduction to Magnetos and Alternators

Magnetos and alternators are essential components in engine ignition and electrical systems, where magnetos generate electricity through rotating magnets and coils without requiring an external power source, making them ideal for small engines or aviation applications. Alternators produce alternating current by rotating a magnetic field within stationary coils and rely on an external battery for excitation, commonly used in automotive and industrial engines to provide stable electrical power. The fundamental difference lies in their energy generation methods: magnetos are self-contained generators, while alternators depend on external power to initiate and maintain electric output.

How Magnetos Work: Fundamentals Explained

Magnetos generate electricity by using a rotating magnet to produce a changing magnetic field, which induces current in the coil windings. This self-contained ignition system operates independently of a battery, making it highly reliable for aircraft and small engines. The fundamental principle relies on electromagnetic induction, converting mechanical energy into electrical energy to create high-voltage sparks needed for ignition.

Alternator Basics: Key Principles and Operation

An alternator operates by converting mechanical energy into electrical energy using electromagnetic induction, where a rotating magnetic field created by the rotor induces alternating current (AC) in the stator windings. Key principles involve the rotor's field winding energized by a small DC current, producing a magnetic flux that constantly changes as the rotor spins within the stator, generating AC voltage. The alternator's voltage regulator maintains output voltage consistency, making it essential for automotive applications and replacing traditional magneto systems due to its higher efficiency and reliable power supply.

Historical Evolution: Magneto vs Alternator

The magneto, developed in the late 19th century, was the primary ignition source in early internal combustion engines due to its ability to generate current without a battery. Alternators, introduced in the mid-20th century, rapidly replaced magnetos by providing more efficient electrical output and better support for vehicle electrical systems at varying engine speeds. The shift from magneto to alternator marks a significant evolution in automotive electrical technology, enhancing reliability and power generation for modern vehicles.

Performance Comparison: Efficiency and Output

Magnetos generate electrical power independently from the engine's battery system, providing consistent output even at low speeds, which is crucial for reliable ignition performance in aviation and small engines. Alternators, on the other hand, produce higher efficiency and greater electrical output at varying engine speeds, making them ideal for modern vehicles with multiple electronic components requiring stable power supply. Understanding these differences helps you choose the right system based on efficiency needs and output demands for your specific application.

Applications: Where Magnetos and Alternators Are Used

Magnetos are commonly used in small engines, aircraft, and vintage cars due to their self-contained ignition system that does not rely on a battery. Alternators, on the other hand, are prevalent in modern automobiles, trucks, and motorcycles as they efficiently generate electrical power to recharge batteries and support electrical components. Understanding the applications can help you choose the appropriate system for reliable engine performance and electrical power generation.

Reliability and Maintenance Considerations

Magnetos offer high reliability with their self-contained ignition system, requiring minimal maintenance due to the absence of external power sources and batteries. Alternators, while generally dependable, depend on battery and electrical system health, increasing maintenance complexity and potential failure points. Regular inspection and upkeep of brushes, bearings, and connections are crucial for magnetos, whereas alternators demand more frequent electrical diagnostics and battery condition monitoring.

Cost Analysis: Magneto vs Alternator

Magnetos typically have a higher initial cost compared to alternators due to their durable, self-contained design requiring less external power. Alternators often prove more cost-effective over time, as their maintenance and repair expenses are generally lower and they benefit from widespread availability of parts. When evaluating total lifecycle costs, alternators tend to offer better value in modern automotive and industrial applications, while magnetos remain preferable for specific high-reliability or off-grid scenarios despite the upfront premium.

Advantages and Disadvantages of Each System

Magnetos provide reliable and independent power generation without requiring a battery, making them ideal for aviation and small engines where consistent ignition is critical. However, their mechanical complexity and weight can be drawbacks compared to alternators, which offer lighter design, higher efficiency, and the ability to charge a battery while supplying electrical power. Your choice between magneto and alternator systems depends on the specific application, balancing reliability against efficiency and maintenance needs.

Future Trends in Electrical Generation Technologies

The future of electrical generation technologies is rapidly shifting from traditional magneto and alternator systems toward advanced smart grid integration and renewable energy sources like solar and wind that demand highly efficient power electronics. Magnetos, once favored in low-maintenance applications, face obsolescence due to their limited scalability and inability to interface with digital controls, whereas alternators evolve with improved materials and electronics to support hybrid and electric vehicles. Your choice of electrical generation technology must consider these trends to ensure compatibility with next-generation energy systems and sustainability goals.

Magneto vs Alternator Infographic

electrown.com

electrown.com